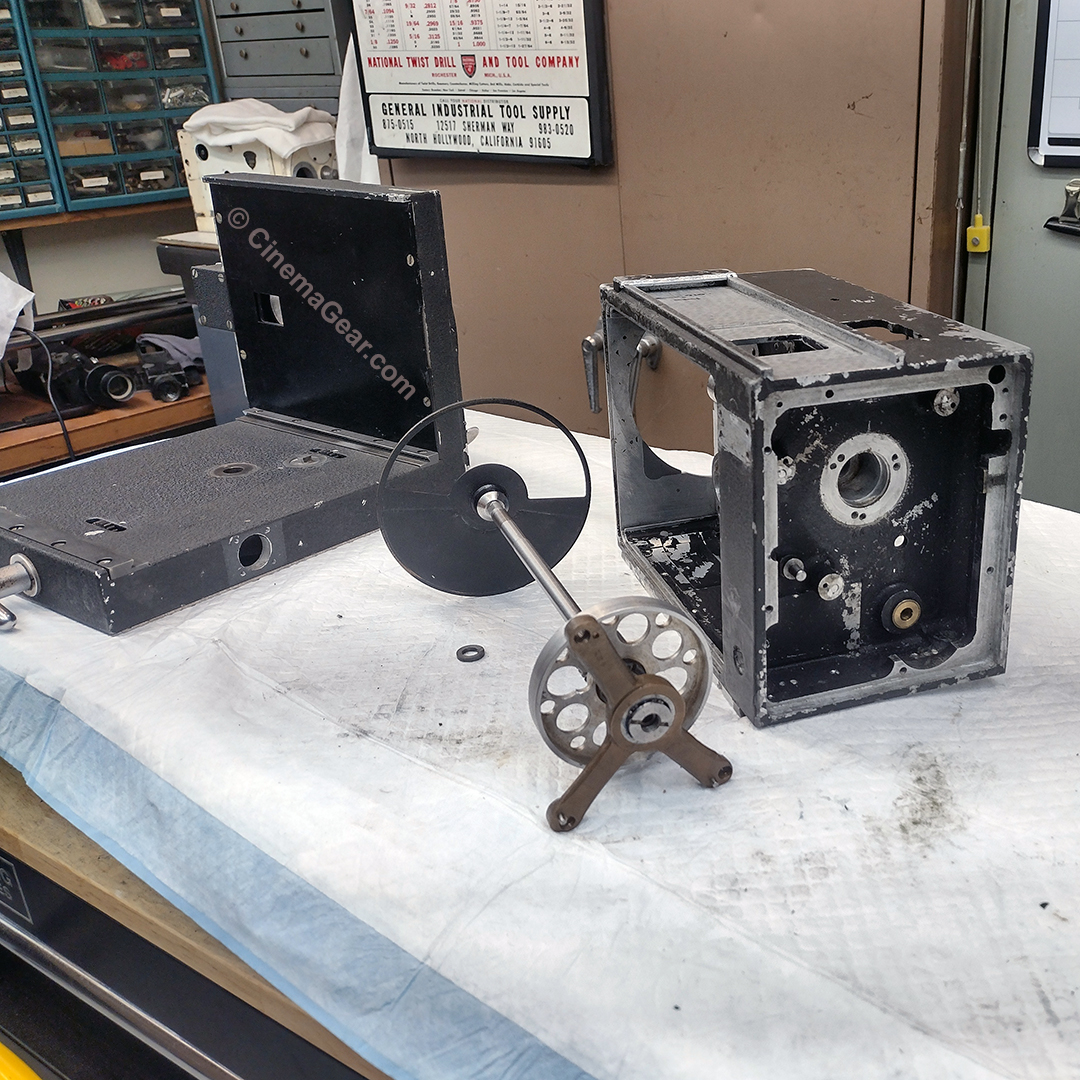

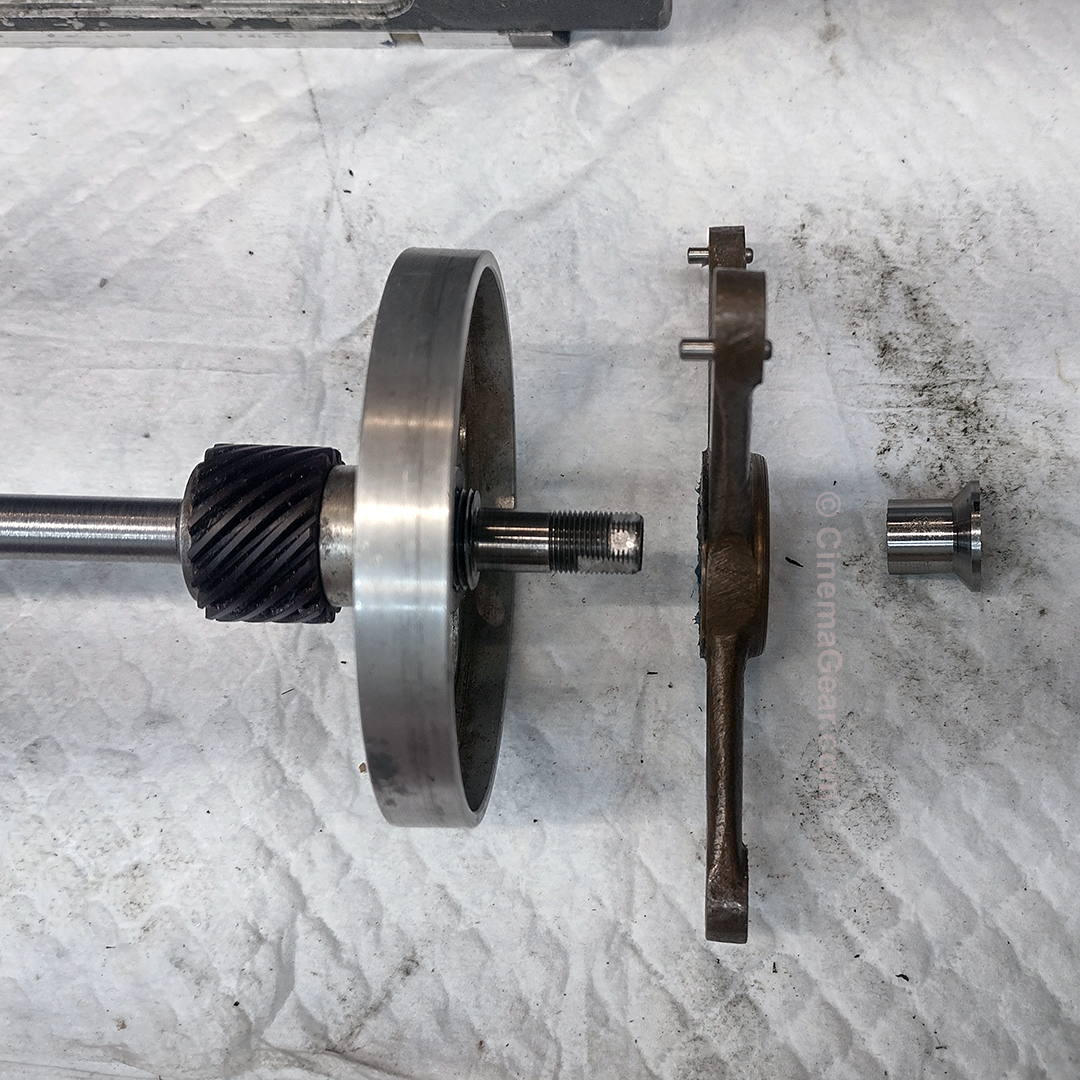

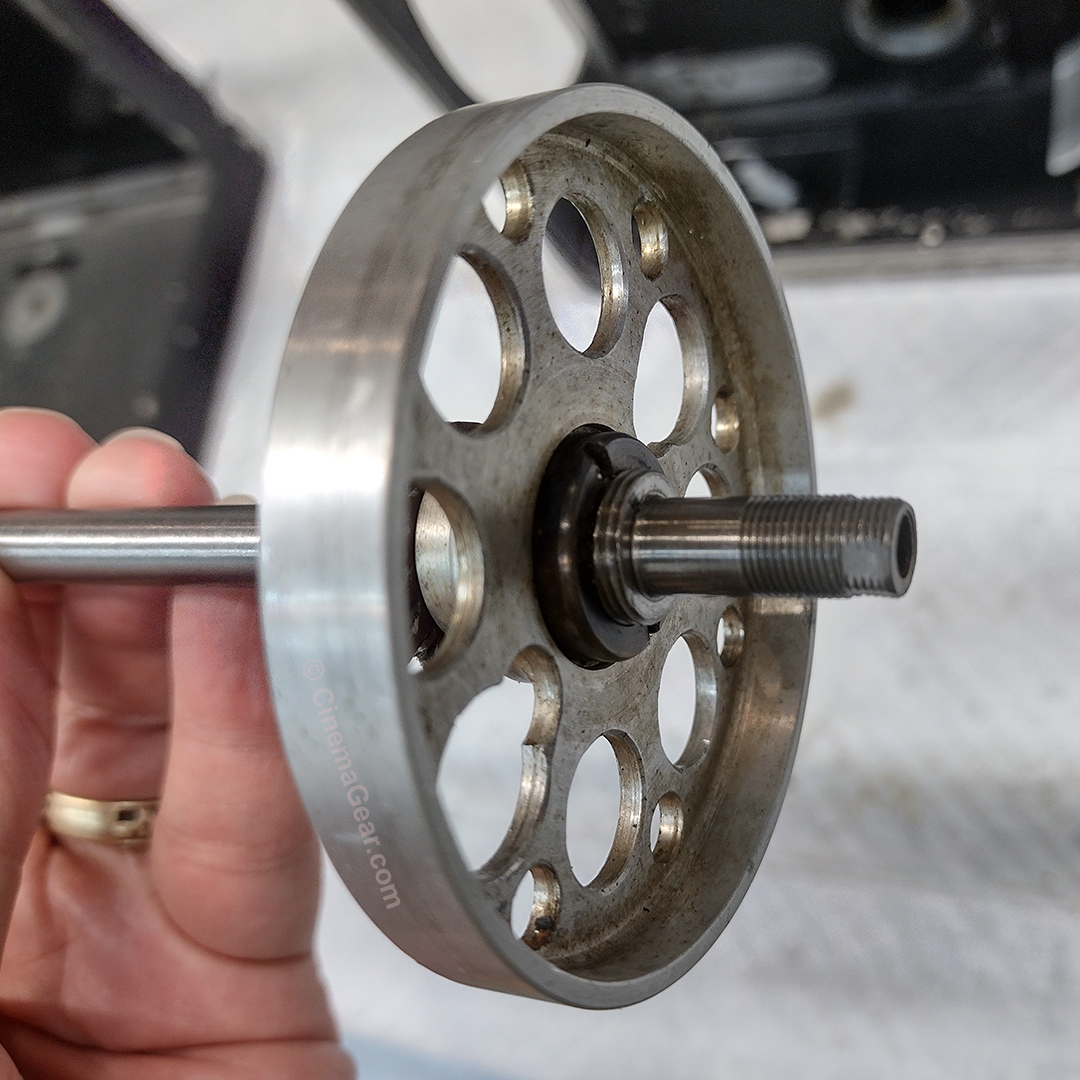

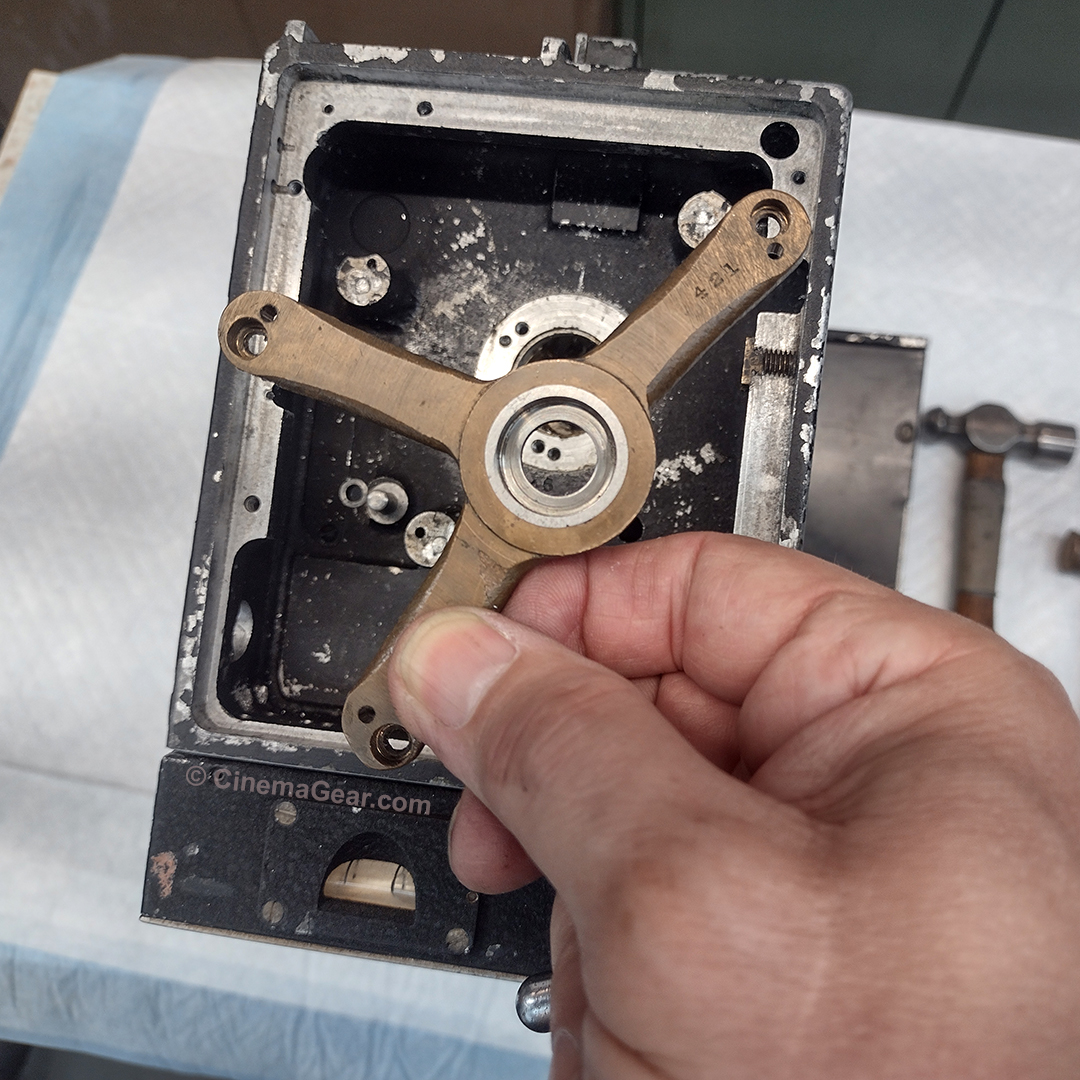

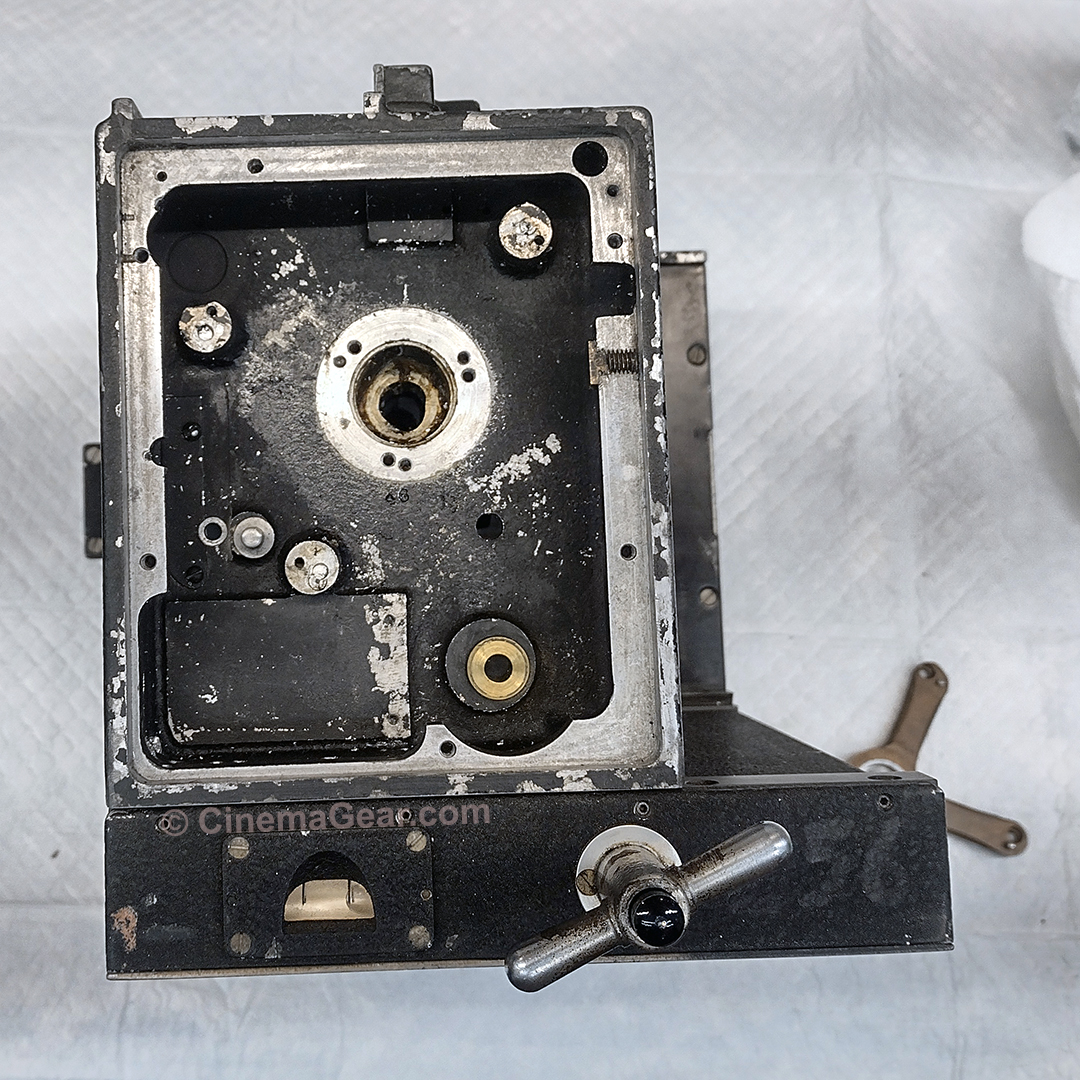

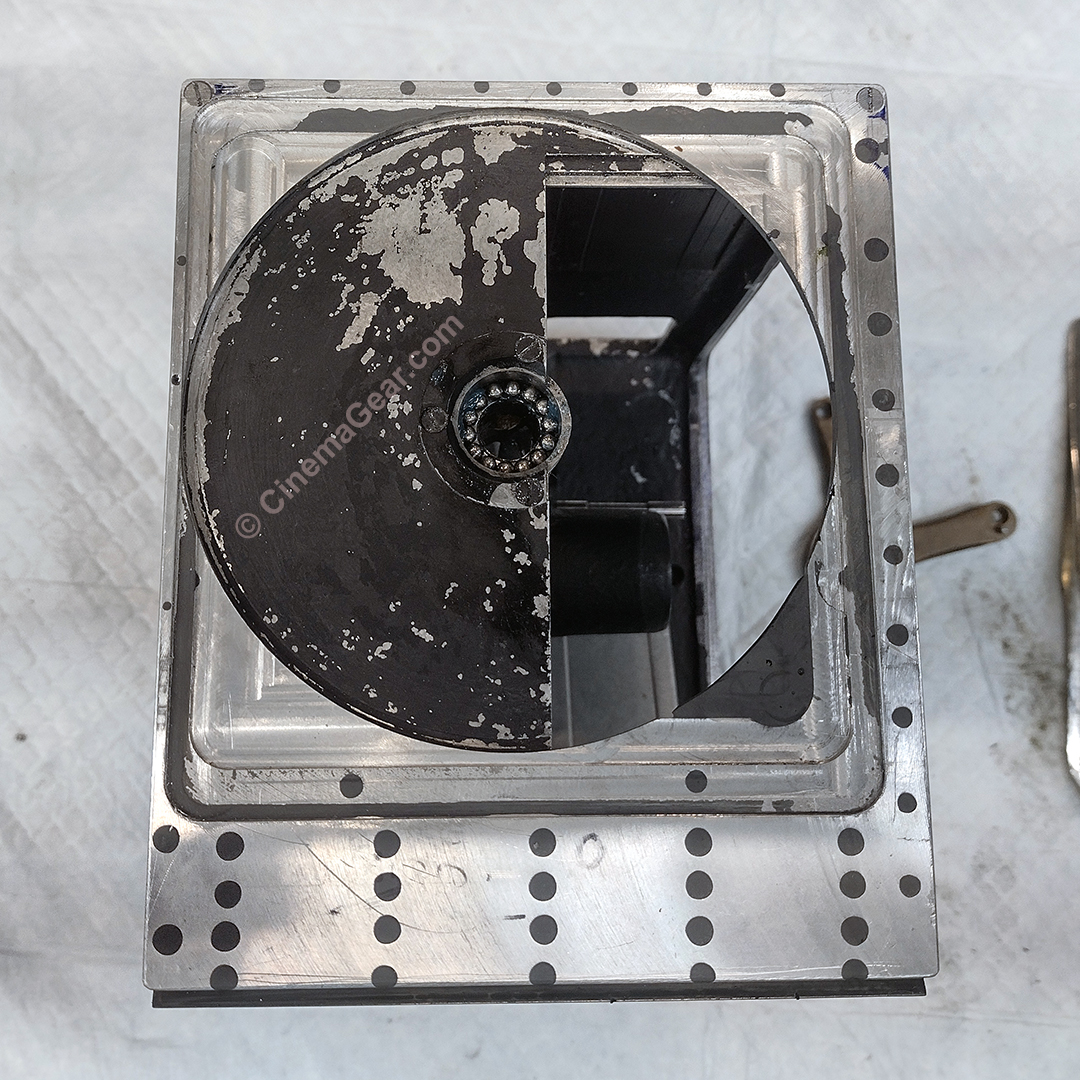

Why is it that the jobs that are supposed to be the simplest always turn out to be the most complicated? Thinking that the most labor-intensive part of the restoration of Mitchell 46 was behind me now, I was supposed to be at the point where I reassemble the working components of the camera, set everything so it is in time, confirm that the camera is now complete, and take it all apart one last time for painting. However, this was apparently not to be just yet. By way of explanation, the main shutter shaft on the Mitchell Standard fits between 2 adjustable bearing races that thread together in order to remove any backlash and keep the main shutter shaft centered to the overall drive components. The previous modifications somehow removed the rear bearing support, filled the holes that they mounted to, and held the rear bearing support in some mysterious way.

My job now was to reinstall the main shutter shaft with a replacement rear bearing support, indicate the main shutter shaft so it is running true and parallel to the shutter’s drive components, drill and tap new mounting holes for the rear bearing support, locate dowel pins, and begin reassembling the camera. The back end of the shutter shaft is threaded at 40 threads per inch. The idea behind this being you could micro-adjust the rear bearing race so the main shutter runs as true and friction-free as possible. This is where my whole day fell apart. The rear bearing race would Not thread back onto the shutter shaft. Rude! So until I can solve that problem, the project is at a standstill. The problem appears to be the threads on the shutter shaft itself, and because this is such a fine thread and the shutter shaft is an irregular shape, I am not yet sure how to repair the threads.