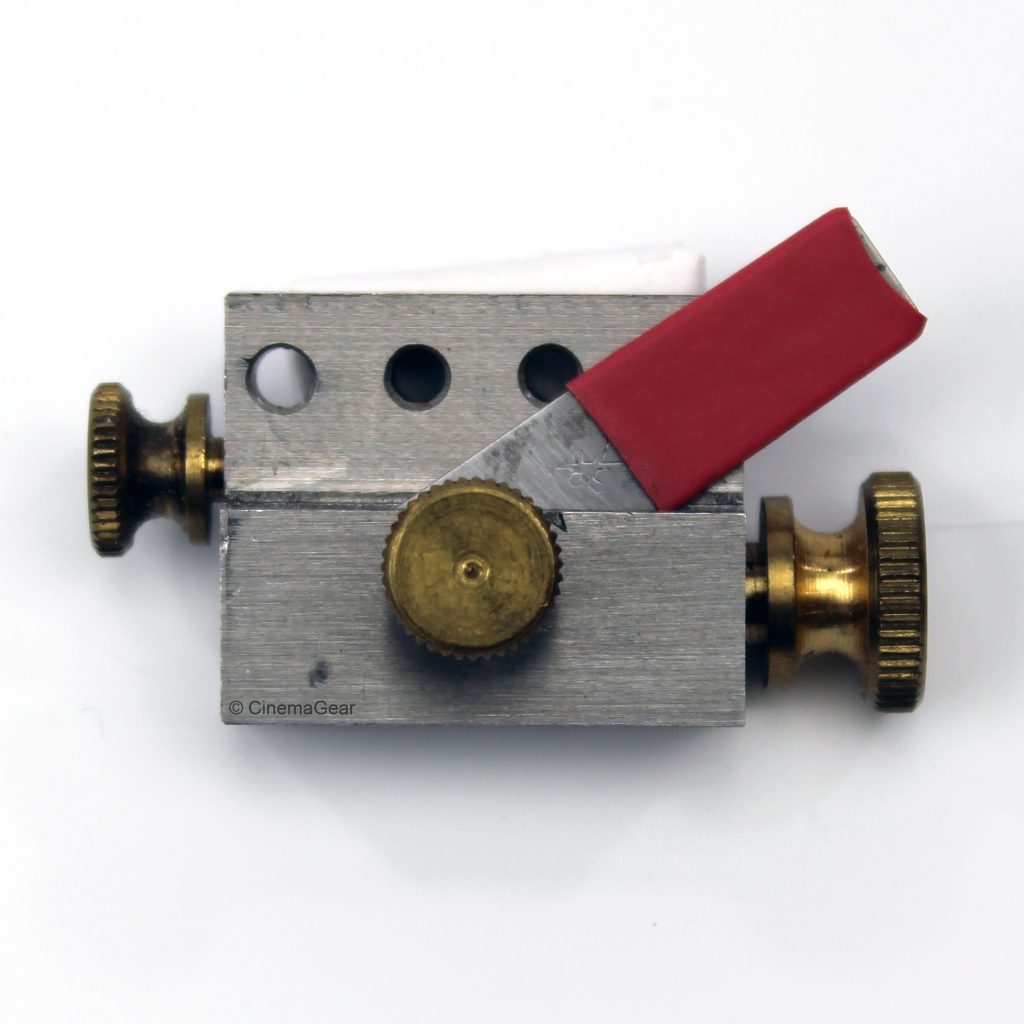

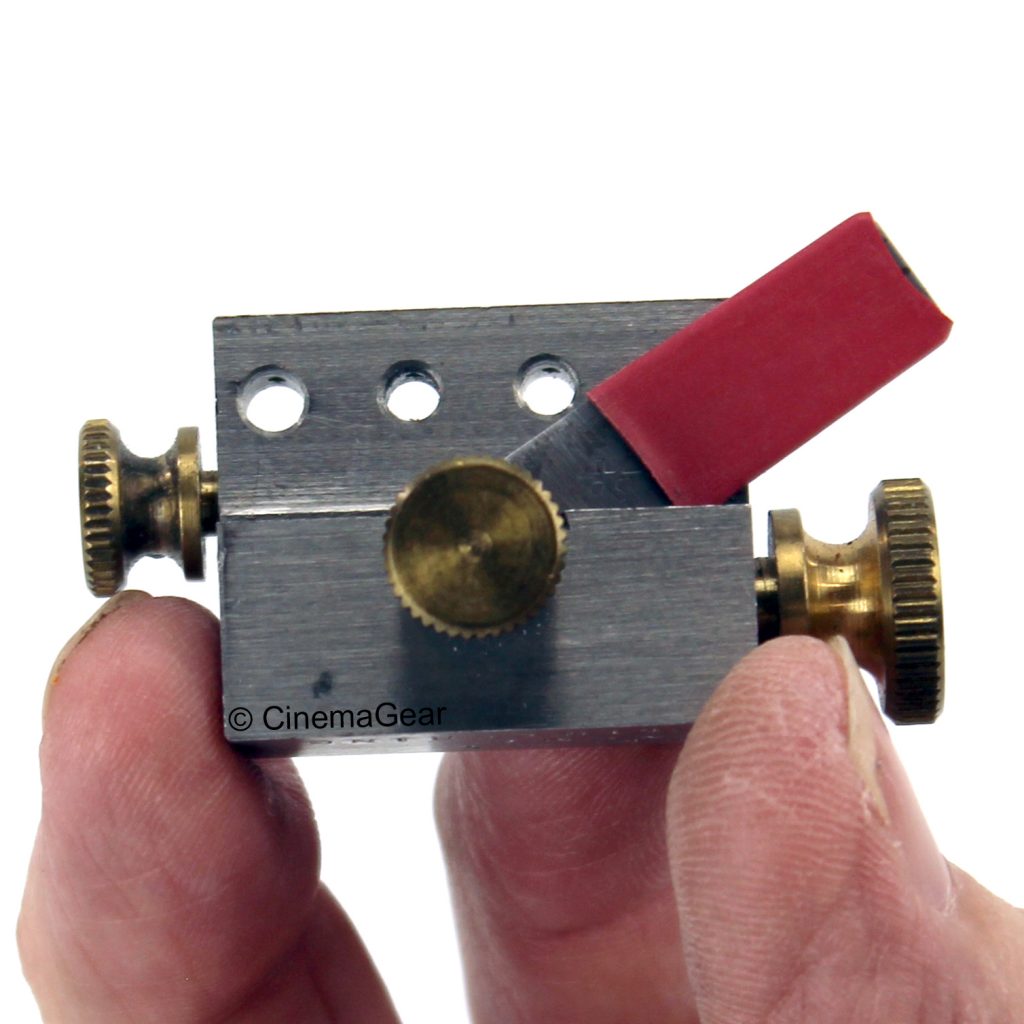

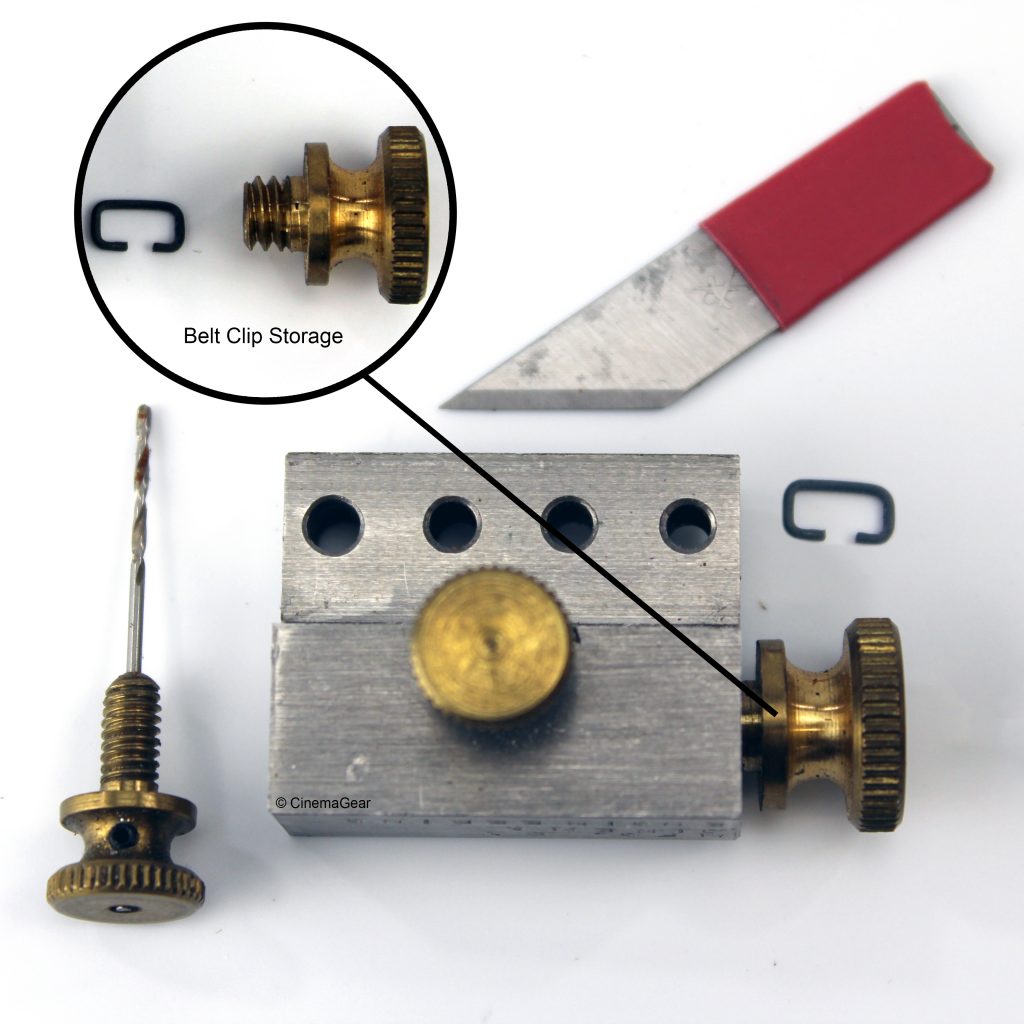

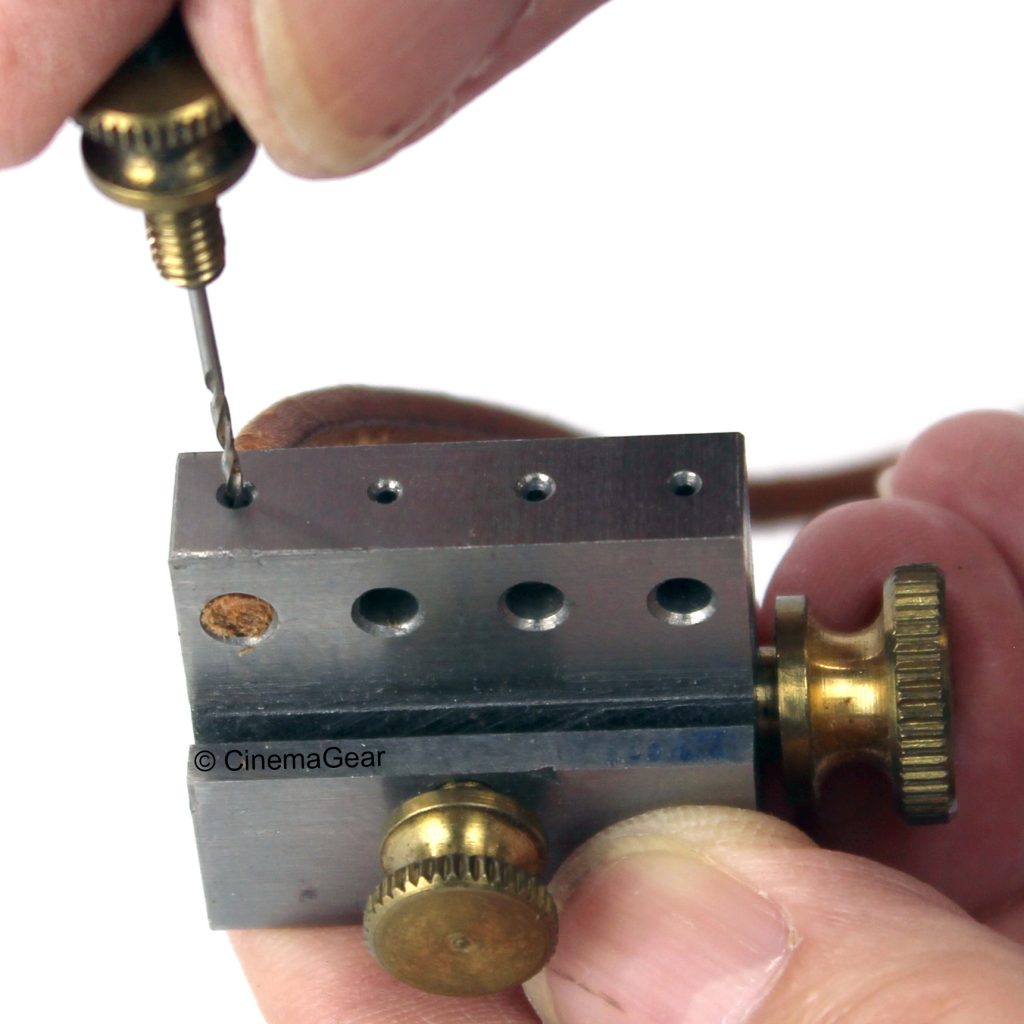

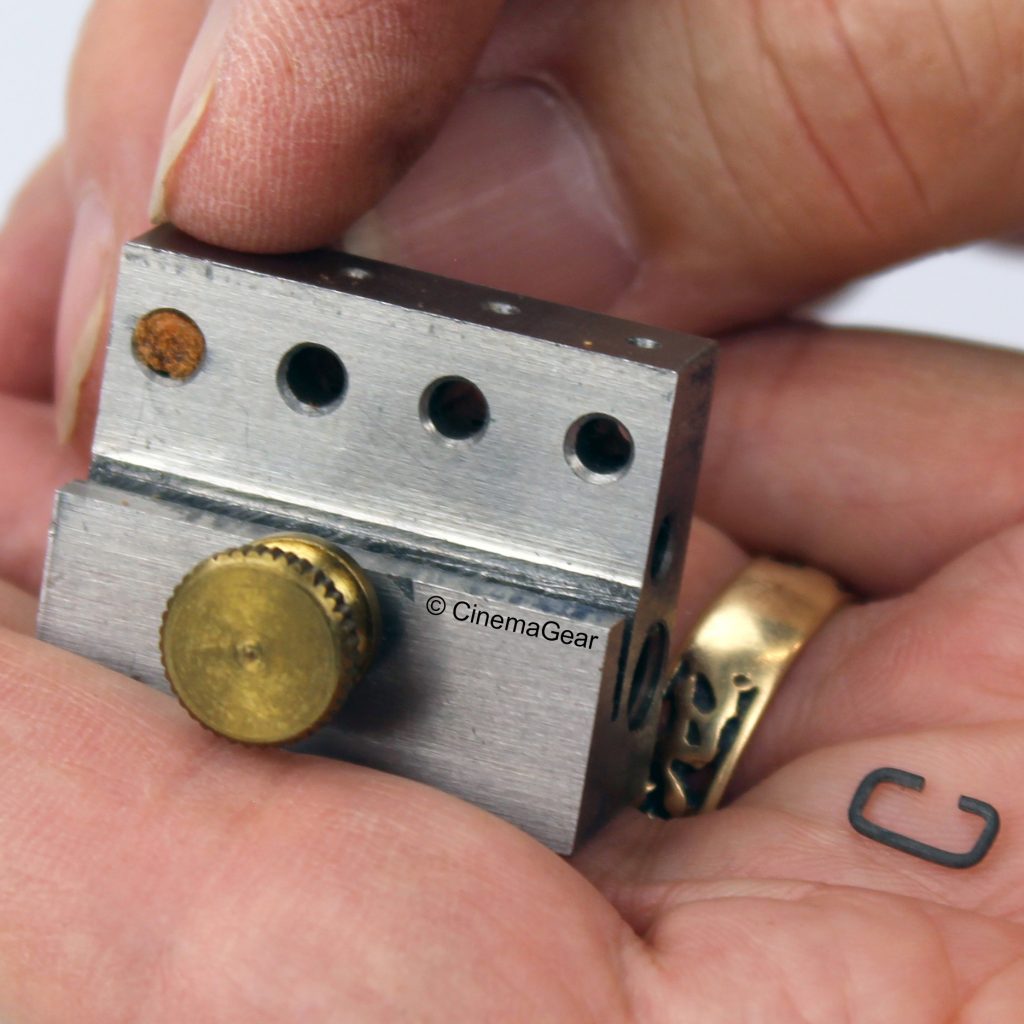

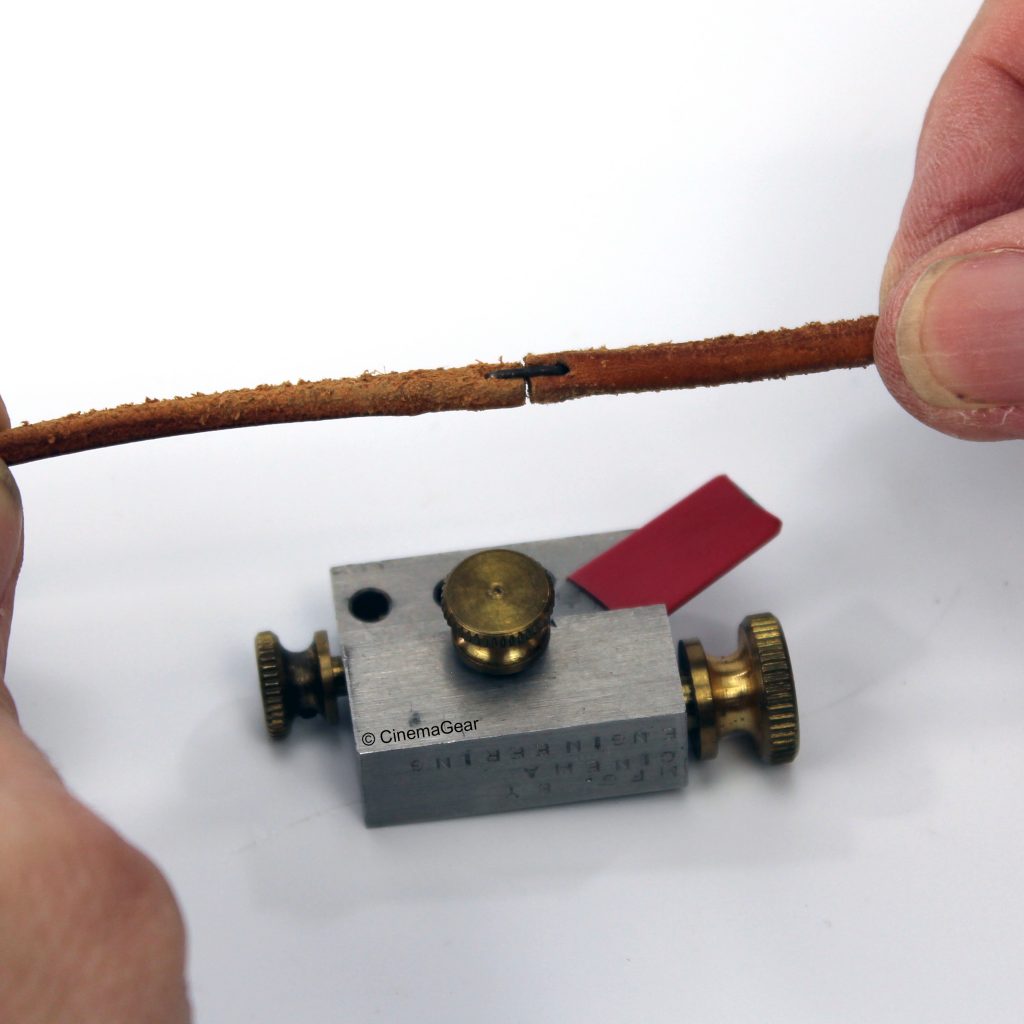

In the days of yore, back when I was shooting movies with Mitchell and Bell & Howell cameras, we often struggled with getting leather belts spliced together so they ran quietly and smoothly. Several of the assistant cameramen I worked with had a bag full of pieces that they would use to splice belts together. It seemed to me that a single tool could be made to do this job. The tool needed to do 5 things well: It needed to drill the coupler hole a precise distance from the splice. It needed to accommodate several different diameters of belt. And it needed to have a sharp cutting blade, a properly sized drill or punch, and a place to store the belt clips. I designed this splicer to be machined out of a single block or steel, and machined it so that the cutting surface was the correct distance from the drilled hole. I added 4 slightly differently sized guide holes to allow for the average leather belt sizes. The finished unit kept all of the pieces you would need to splice a leather belt contained in a single device that was easy to throw in a bag.