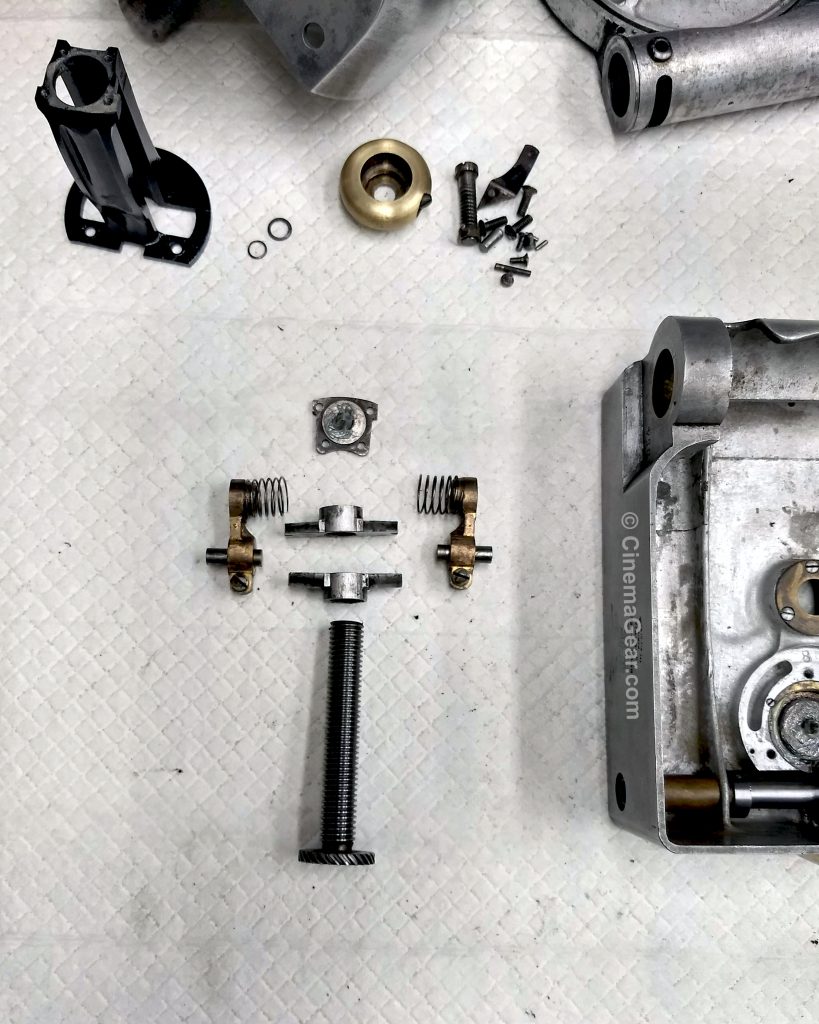

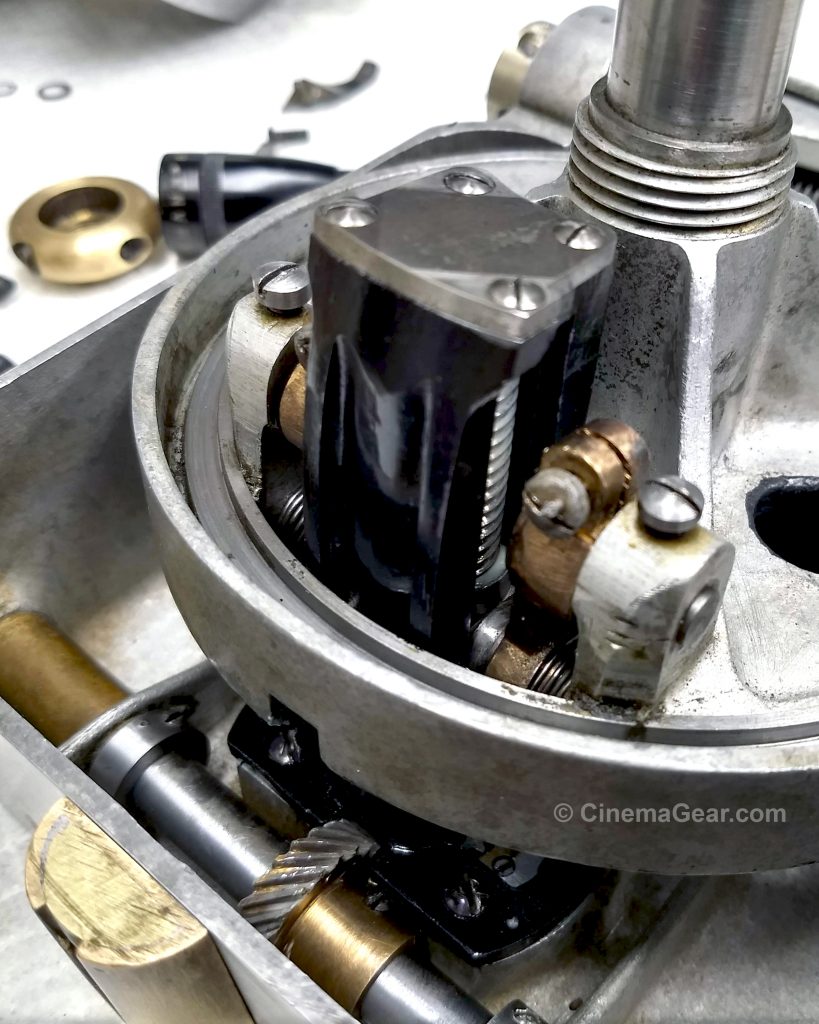

Parvo pan and tilt head restored and waiting for its camera! Now that I’ve had my hands on all the bits and pieces that make this unit pan and tilt, there are still a few very interesting mechanisms that make this head unique. Our 2nd photo shows one of the most interesting assemblies; the jackscrew that raises and lowers the tilt axis. The designers chose a combination of split nuts riding on square threads between two pointed centers, and a set of spring-loaded drive axles to control backlash and make the tilt axis run very smoothly. You can see in photo 3 how that all came together. The split nuts ride on the jackscrew and lift the tilt head on the two axles.

The other two interesting features are how every axis has a fine adjustment to control backlash. Photo 4 shows a small, square thread jackscrew that actually adjusts the contact angle for the worm gear on the pan axis. Photo 6 shows another square thread jackscrew that adjusts the engagement of the worm gear on the pan axis. Just about every moving part on this pan tilt head has one or more fine adjustment to minimize backlash that I found very clever. As for the wooden legs, I decided to leave their original finish intact. Much tar, dirt, and grease were cleaned from the surface with extra fine steel wool. All of the metal parts had rust removed, but because of severe pitting, I chose to paint them. The wooden legs were sealed with a high-quality paste wax, and everything was reassembled.