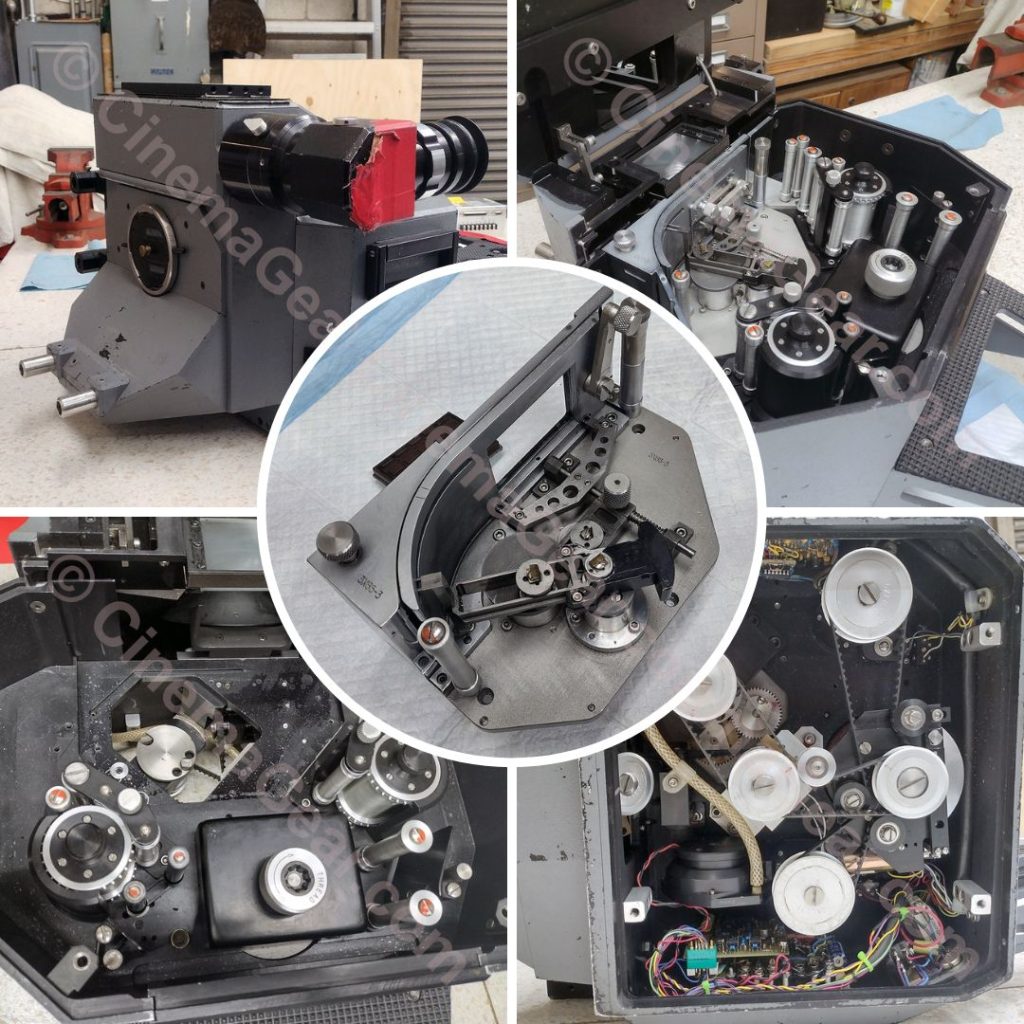

Back in March 2021, I had a chance to evaluate the Fries Engineering version of the IMAX camera to diagnose why it had stopped working. The immediate problem was pretty straight forward: There is a flywheel that is part of the movement, but that also acts as a coupler between the movement and the shutter drive. At some point either during the run cycle or stop cycle, this heavy flywheel sheared off the movement drive shaft it was attached to, leaving the shutter turning but the movement stalled. The owner decided not to move forward with repairs at the time of my initial inspection and took the camera home, but now it is back and ready to be repaired.

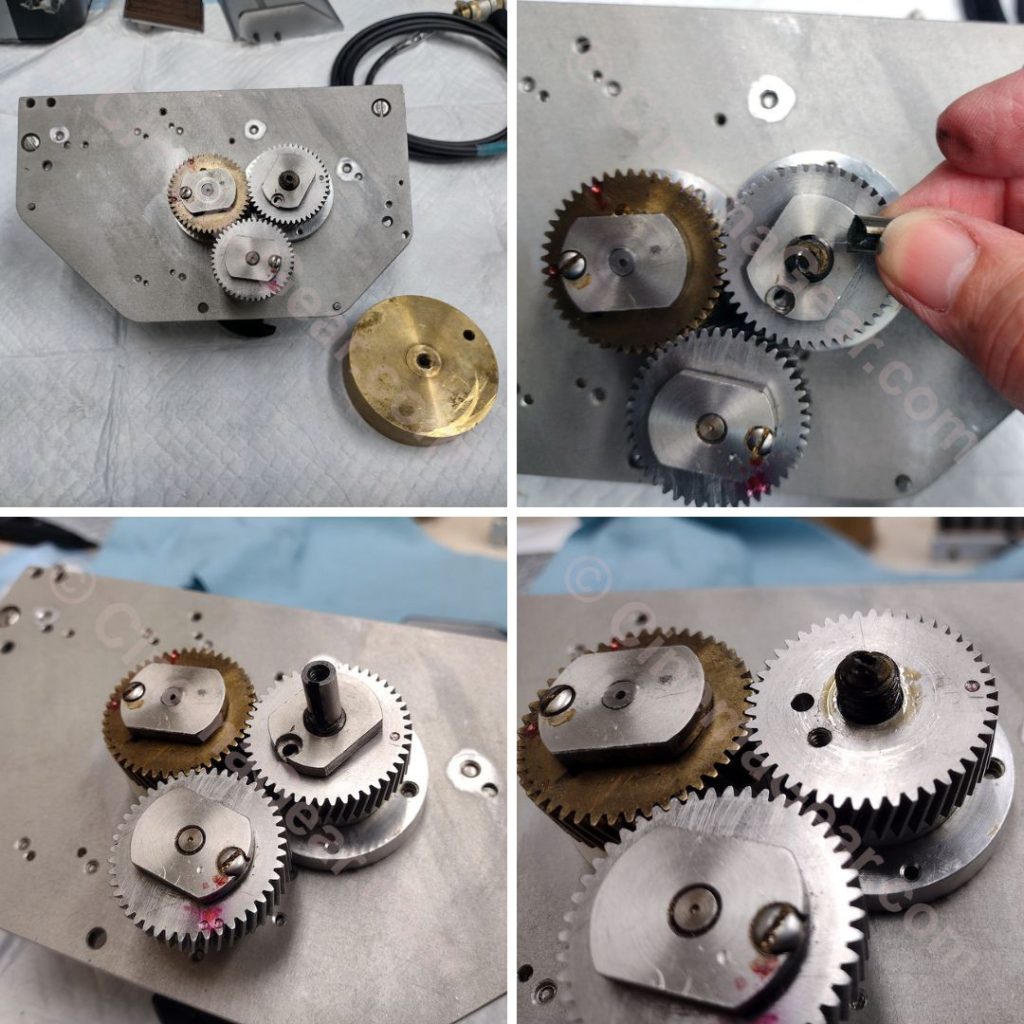

I spent 5 or 6 days reviewing the camera’s condition and trying to come up with a solid, but economical way of bringing this camera back to life. To me, there are two approaches for the repair at hand. The first approach would be to remake the entire pull-down cam assembly and re-balance and re-time everything. This would be a very costly and time consuming process. The second approach that occurred to me is to use the existing gear assemblies that keep the pull-down claw and registration pins in time, and fabricate a new custom coupling that goes between the pull-down claw timing gear and the flywheel assembly. This approach only requires machining a few new parts that are not as precision as the pull-down claw cam assembly. This new coupling takes the place of the sheared flywheel drive shaft.

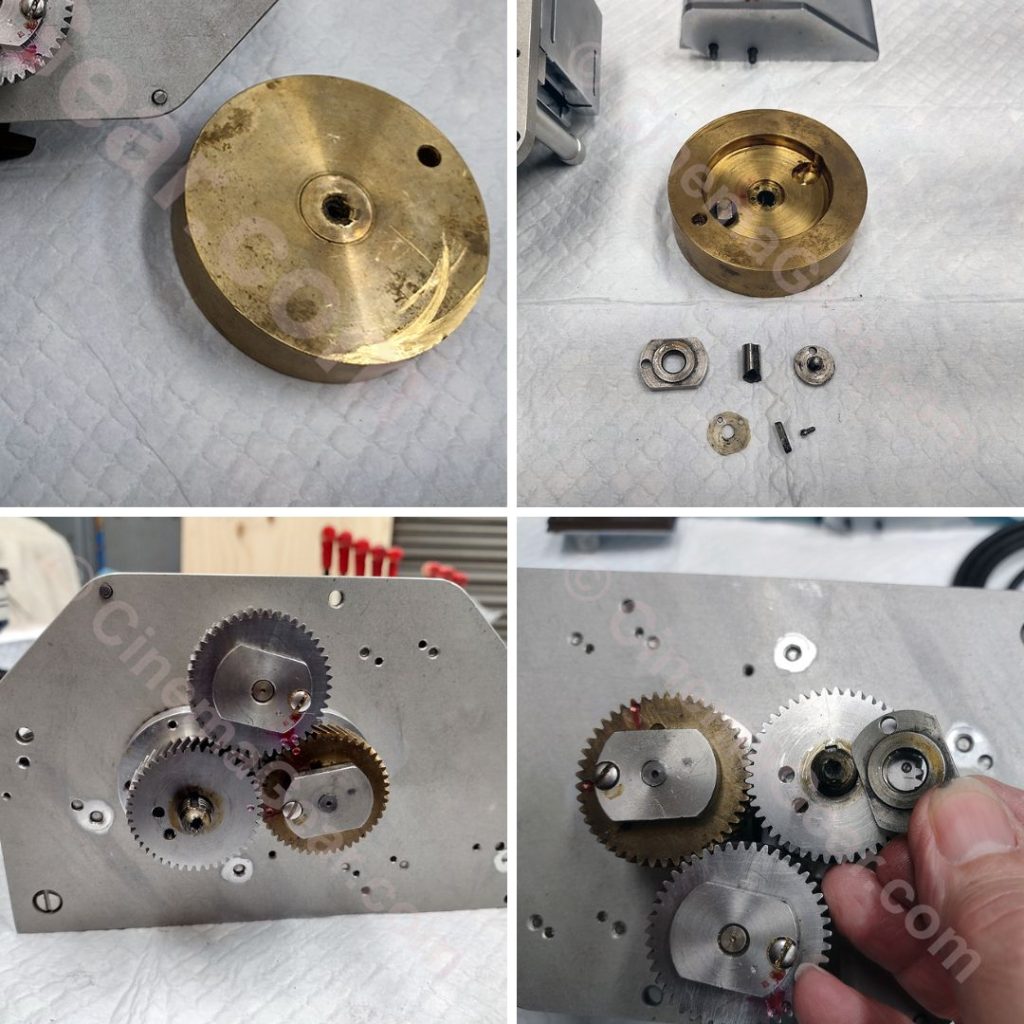

Three major considerations went into this second approach. The first would be to reestablish timing between the movement and the shutter, because the flywheel acts as a coupling between the movement and shutter drive assembly. The second consideration is to dynamically balance the coupling and flywheel so that it doesn’t develop harmonics while it’s spinning. And lastly, to build it in such a way that it is serviceable in the future.

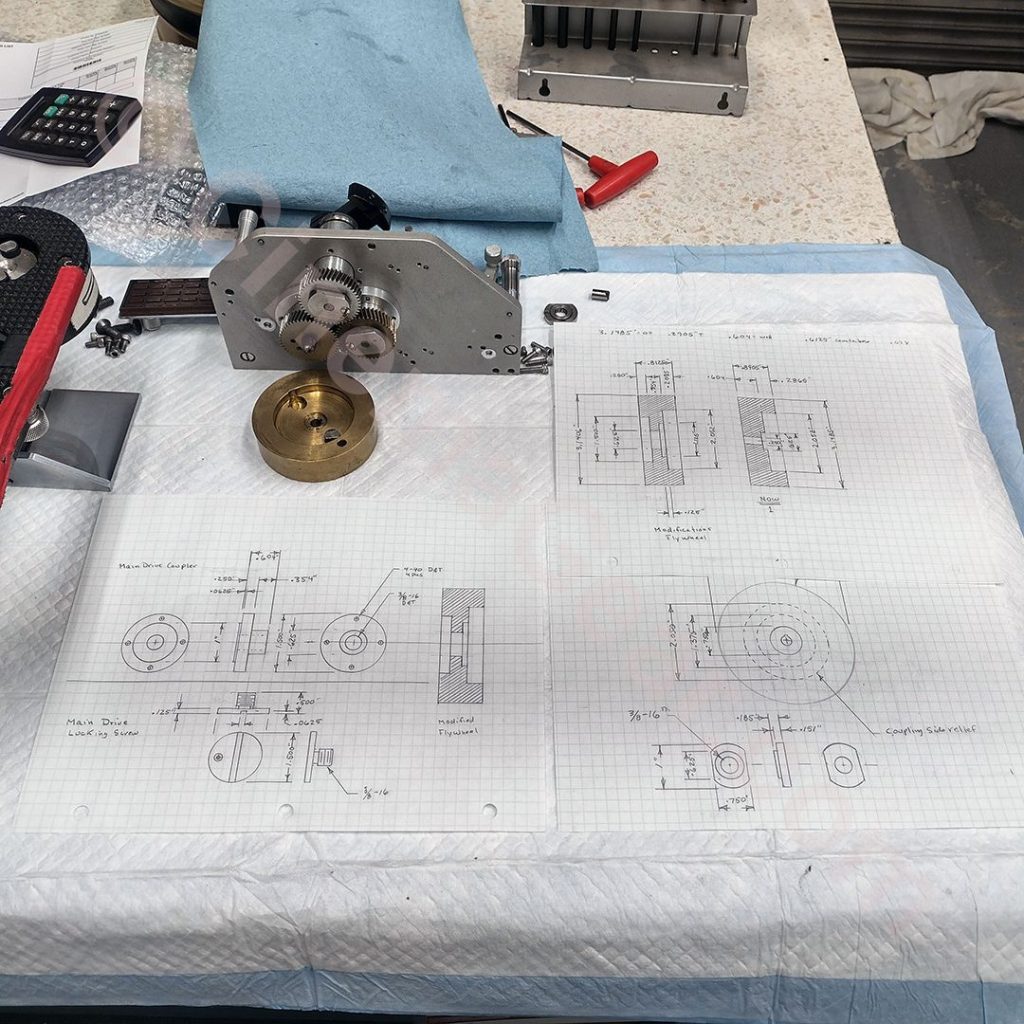

The process I decided on is as follows:

- I will machine a stainless steel coupling that will thread onto the remaining pull-down claw drive shaft and provide a new mounting point for the flywheel that will keep the flywheel centered to the pull-down claw drive shaft and allow for timing adjustments.

- The new coupling will fit into a pocket that will be machined into the existing flywheel so that it can attach to the flywheel with four screws.

- I will machine a center locking nut that will do two things:

- Hold the flywheel to the pull-down claw drive shaft while reestablishing timing

- And then, once timing is established using this locking nut, it will hold everything in place until screws and dowel pins can be located to hold everything in place permanently.

Once all of this is completed, the flywheel, with its new coupling, needs to be dynamically balanced. Then the camera needs to be reassembled and, if all went as planned, it will run film once more. More to come once I make parts.