Last week’s experiments with Showscan lenses got me thinking about the Showscan equipment I have left around the shop. Among these leftover pieces is this CP 65 camera body that lacks most of its electronics and its movement. The camera casting is serial no. 101, and as I looked it over, I thought it would make an interesting display piece. This was one of the cameras built by Jeff Williamson for Cinema Products, and it looks like, over the years, people scavenged much of the internal workings.

The first thing I noticed was that the video tap didn’t allow the one and only stock Showscan magazine I have left to be mounted on the camera without some sort of unknown riser block that I don’t have. The second thing I noticed was that the camera still has its spinning mirrored shutter, ground glass, and viewfinder assembly, but it is missing the relay optics between the viewfinder and the mirrored shutter. As my chances of being able to find whatever they used to mount the magazine on this camera are slim to none, and the video tap assembly is missing almost all of its optics, as well as the video camera, I decided the video tap assembly could be sacrificed. I searched through my collection of optical components to see if I had a prism big enough to work with the remaining viewfinder optics, and lo and behold, I found one of the prisms that was used on an ancient Close Encounters camera and it seemed to work!

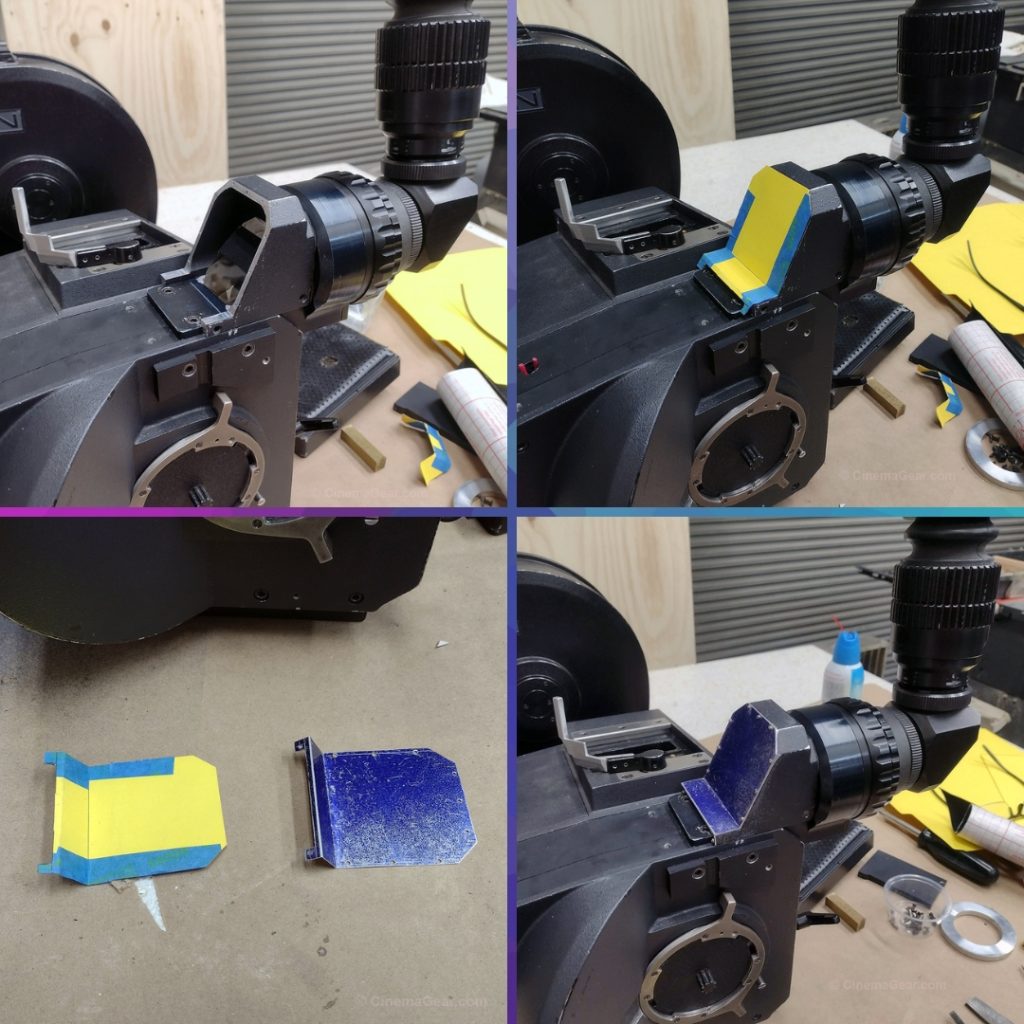

To begin, I removed the video tap housing and determined that I could cut down the original relay optics housing for the viewfinder. With the housing cut down, it meant I could install the replacement prism, use the newly machined piece as the enclosure over the replacement prism, and the whole unit would no longer interfere with the magazine. Then I needed to make some cover plates, one to cover the open end of the newly machined prism housing, and one to cover the recessed area that the video tap was mounted to. After a couple of hours of sheet metal work and some paint, the viewfinder worked once again!

When I originally picked up the camera, there was something rattling inside the casting, and while my hopes of that being the movement were dashed, it turned out to be the upper and lower sprocket assemblies. I decided that I might as well put the sprockets back in the camera and retime everything so that, if a movement magically appeared, I could just put it back in the camera. So I leave this wonderful display piece in this condition: it has the mirrored shutter, the upper and lower sprockets (missing the sprocket keepers), and all the belts and pulleys that would make it run mechanically. It’s a lovely piece, and now the viewfinder is operational and the magazine can mount to the camera. It would make a lovely prop, or an excellent display piece.