Way back in 2019, I was asked to rebuild the missing sections from the Dykstraflex camera moving system so that a working Dykstraflex could be demonstrated at the Academy of Motion Picture Arts and Sciences Galactic Innovations event. This project happened on a tight schedule, and in the middle of me moving my business across town. As the event got nearer and nearer, a couple repairs were done as temporary fixes, with the intention to go back and fix them properly after the event. Then 2020 happened, and we all know how that went. So here we are now, back to complete repairs on the center bearing on the crane’s rotation axis.

Over the years, a few of the major components of the Dylstraflex were lost or misplaced, including the linear actuator that raises and lowers the crane, the cross track assembly, and the lower section of the turntable that allowed the crane to pan. Our original plan was to use the turntable off of a model mover that was supposed to be exactly the same as the turntable on the crane by simply removing the top plate and lowering the crane onto the model mover turntable. But the best laid plans, as they say, oft go awry. The outer bearing race on the model mover turntable matched exactly to the outer race on the crane’s turntable, but the inner bearing was a completely different diameter, and not compatible. So, as a quick temporary solution, I machined a new set of inner bearings to be installed, but we ran out of time to complete this part of the repair. I temporarily installed the bearings with set screws locking the lower bearing race in place, and the crane was able to make its debut.

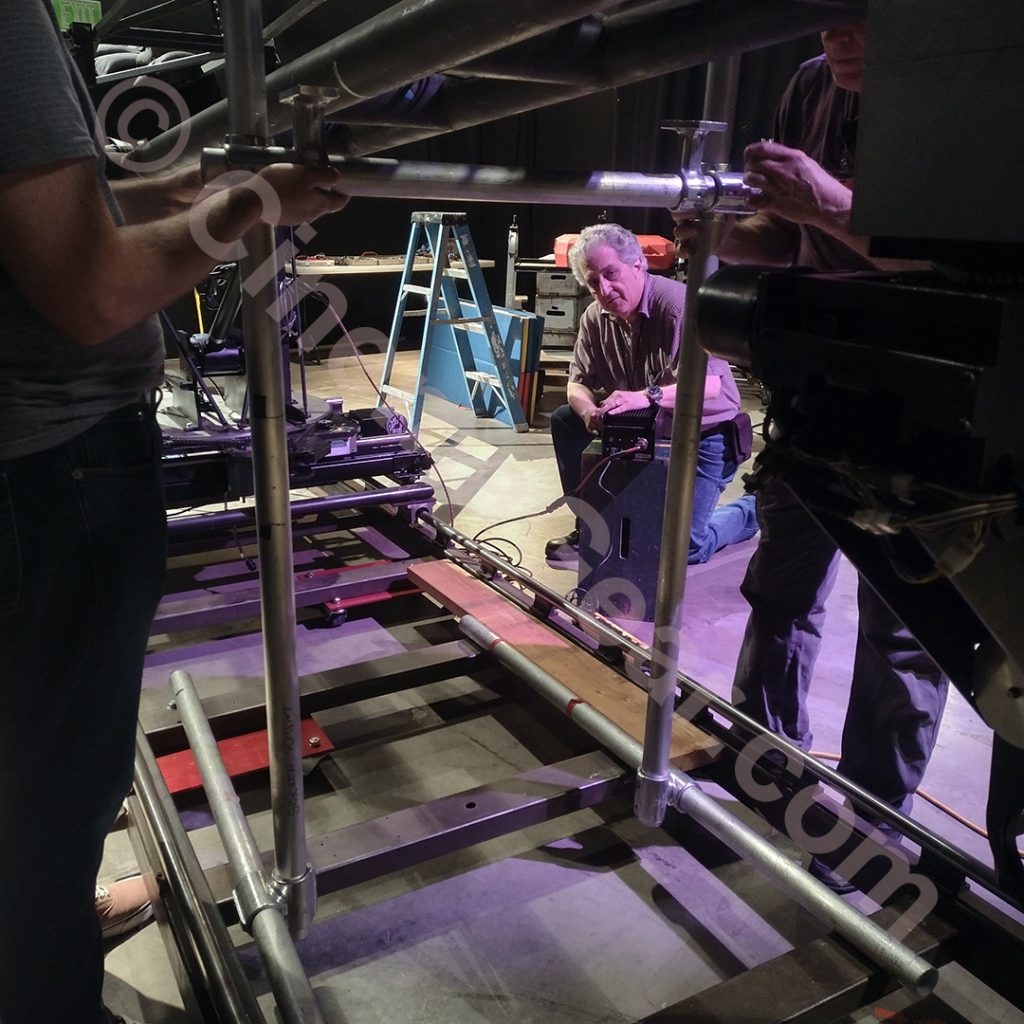

Last week, we were finally able to get underneath the Dykstraflex once more and finish this repair correctly. With the help of Joe Di Gennaro, Cesario Tio, Luke Crawford, and Theo Gluck, the Dykstraflex was raised up off of its track and set on apple boxes so we could access the lower bearing. I removed 3 of the 4 set screws that held the lower bearing in place, transfer punched one of the holes, drilled and tapped the first new mounting hole, installed a screw and lock washer, then repeated those steps for the three remaining holes. Then we lifted the crane back up off of the apple boxes and lowered and installed it back onto the track. Finally, we used a single-axis stepper motor driver that was kindly lent to us by Joe Lewis (from General Lift) to park the Dykstraflex on its support scaffolding and move it back to its storage spot. Other than being showered with aluminum chips, it was wonderful to finally get the Dykstraflex properly repaired