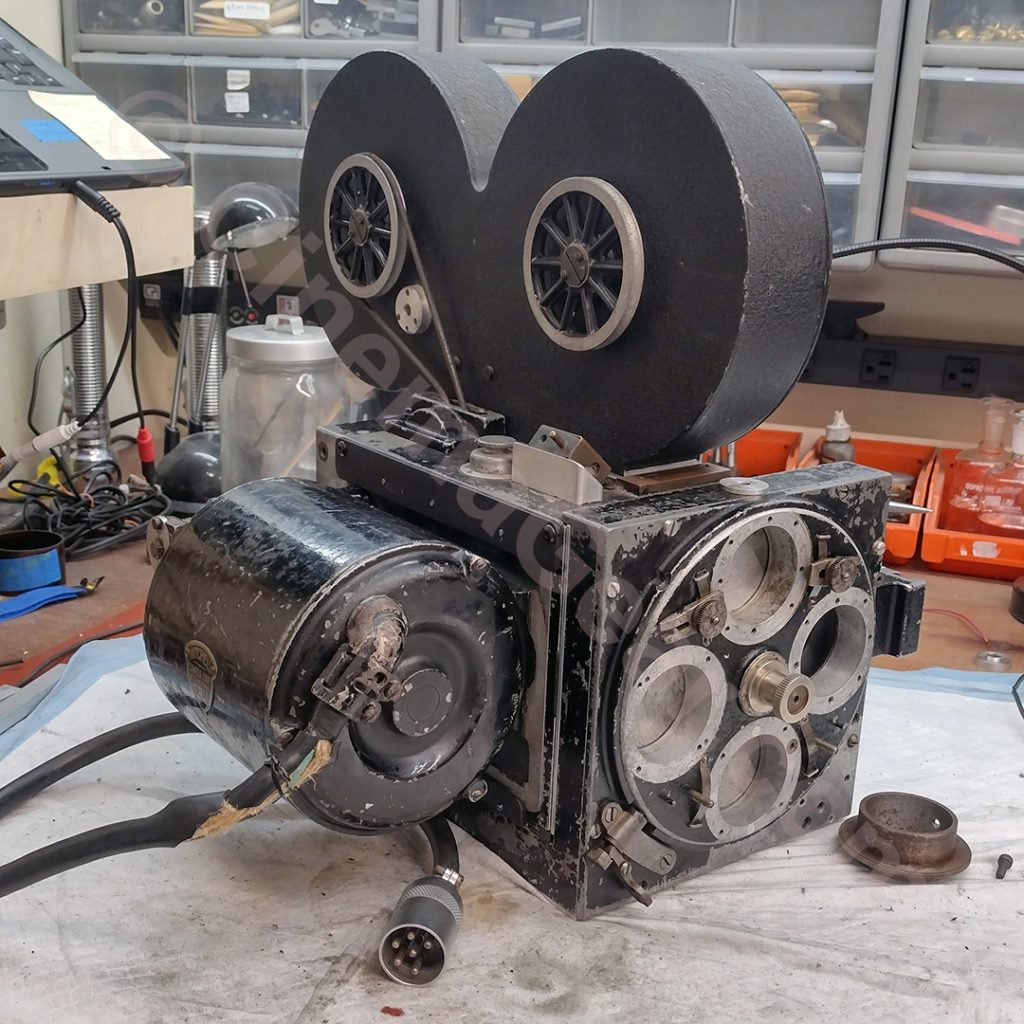

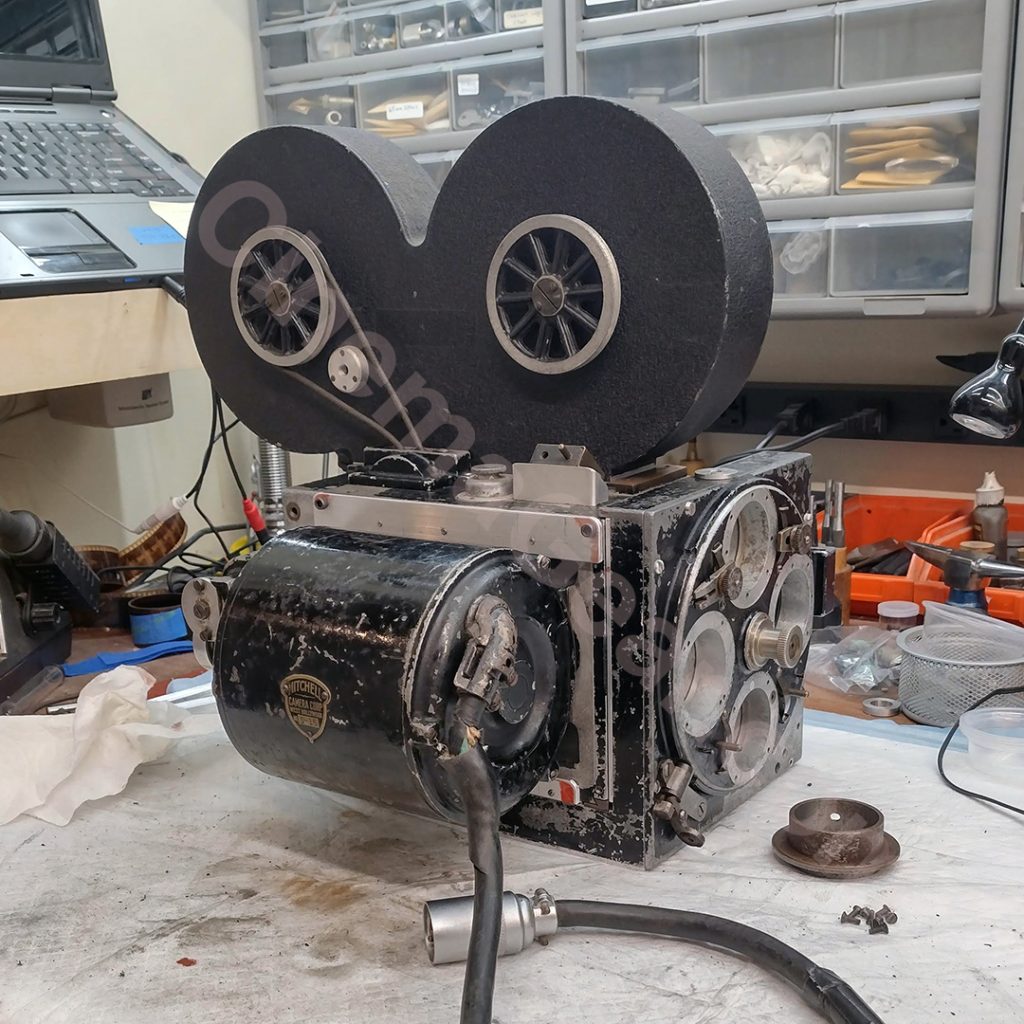

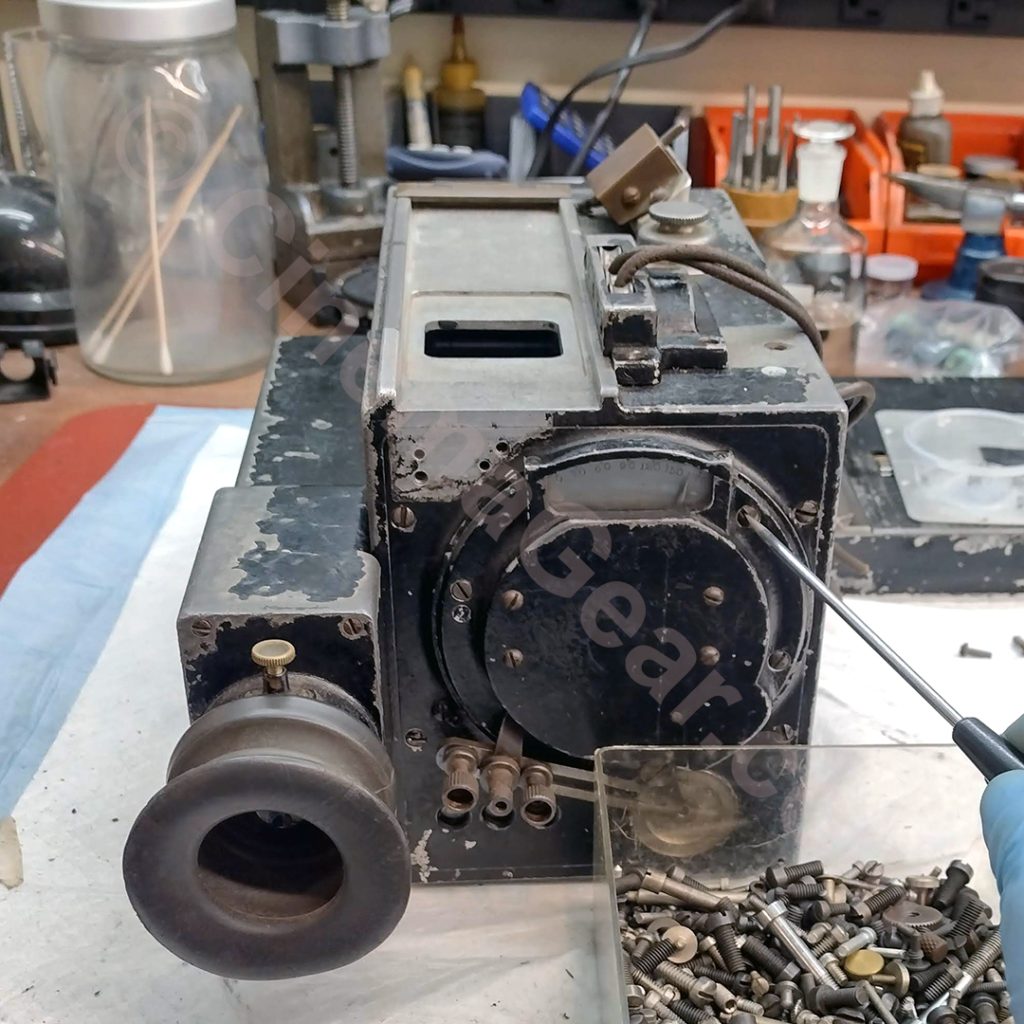

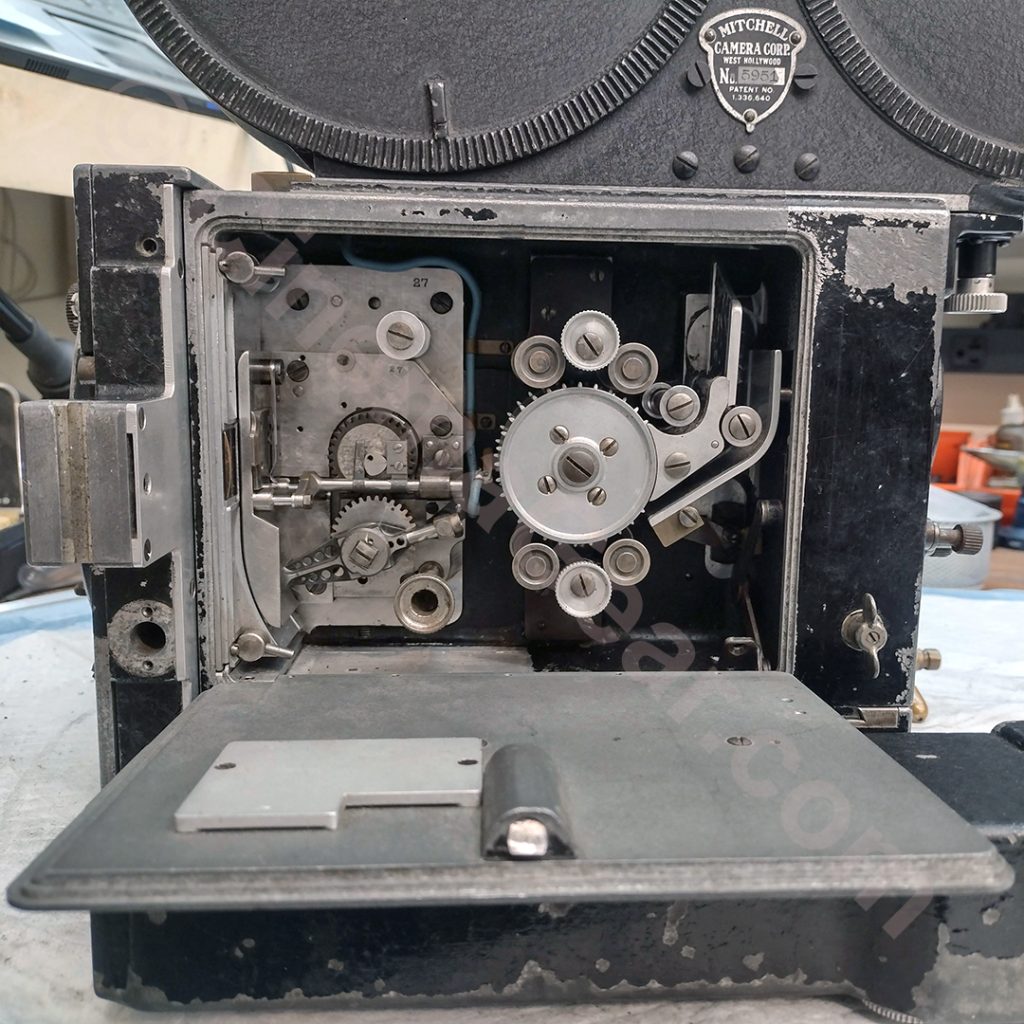

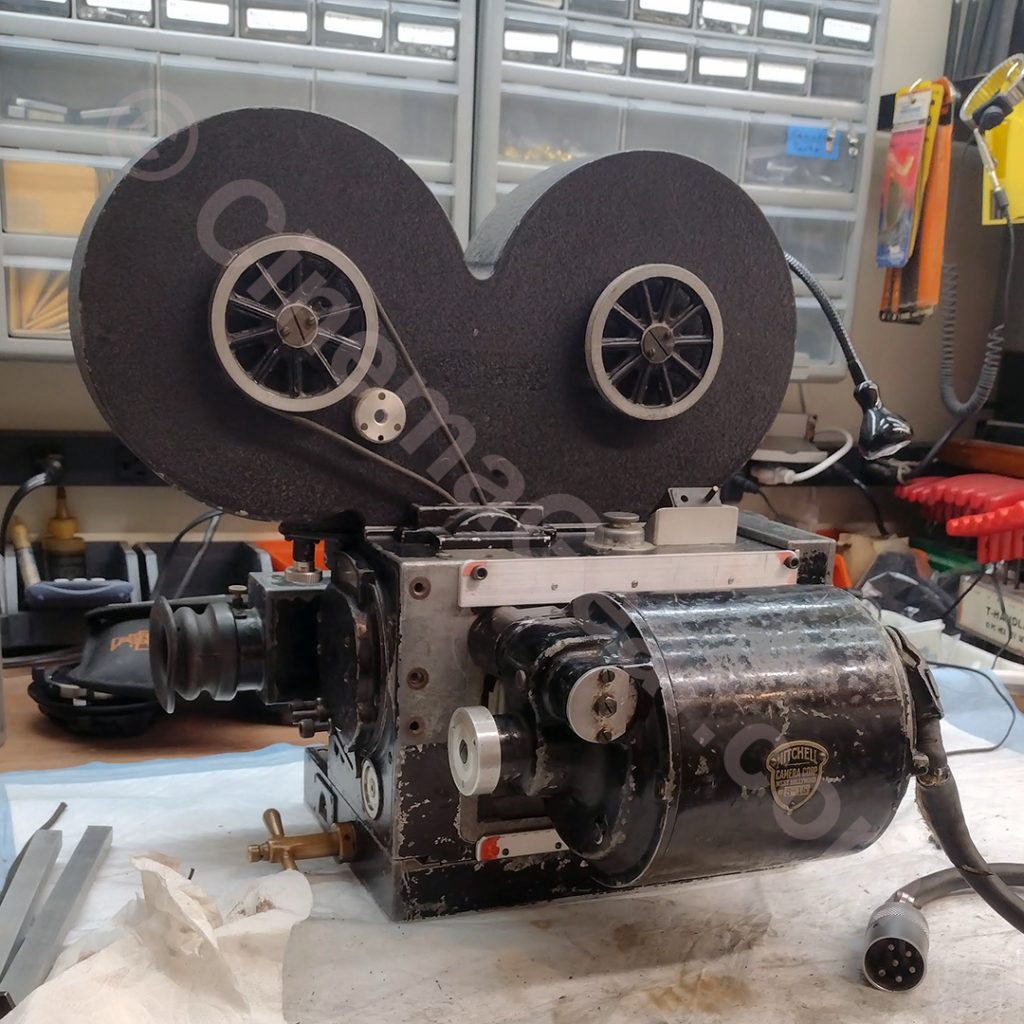

Those of you who have been following me for a while now know how much I love and admire Mitchell cameras. A few weeks ago, I was lucky enough to have Mitchell Standard no. 27 left in my care for some basic maintenance and tlc. This very early Mitchell camera was bought by MGM some time in 1923 and was later installed in one of their custom studio Bungalow Blimps. The camera bears the marks of its century of filmmaking at MGM, and later at a studio in Australia, and so needed some really minor repairs and maintenance.

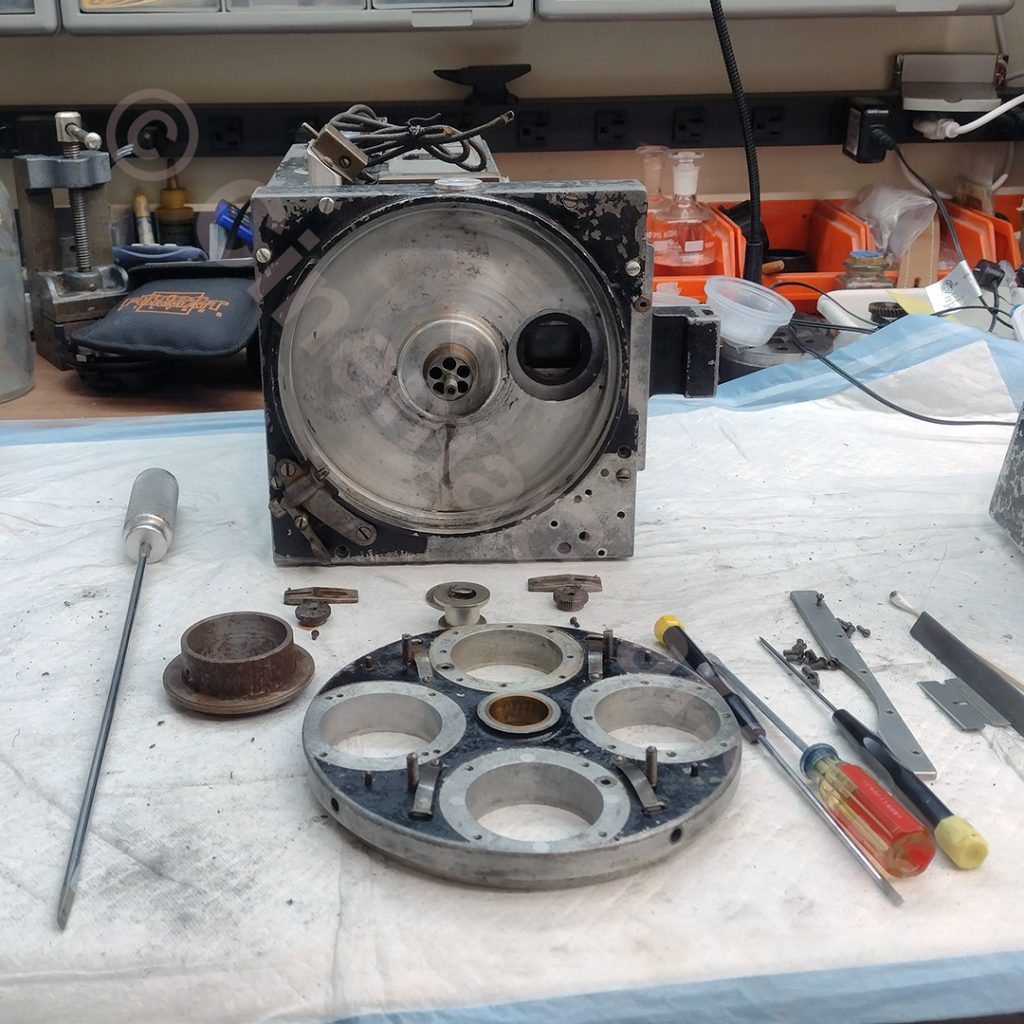

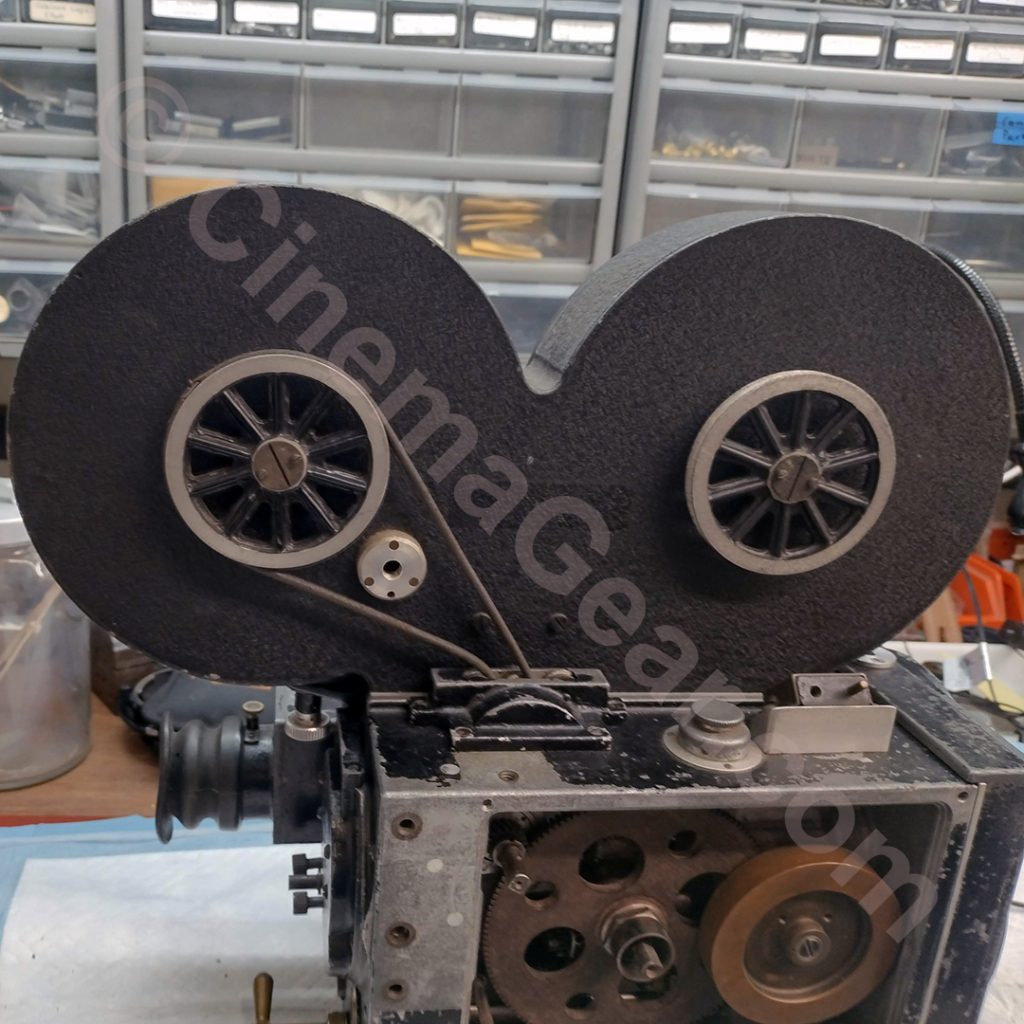

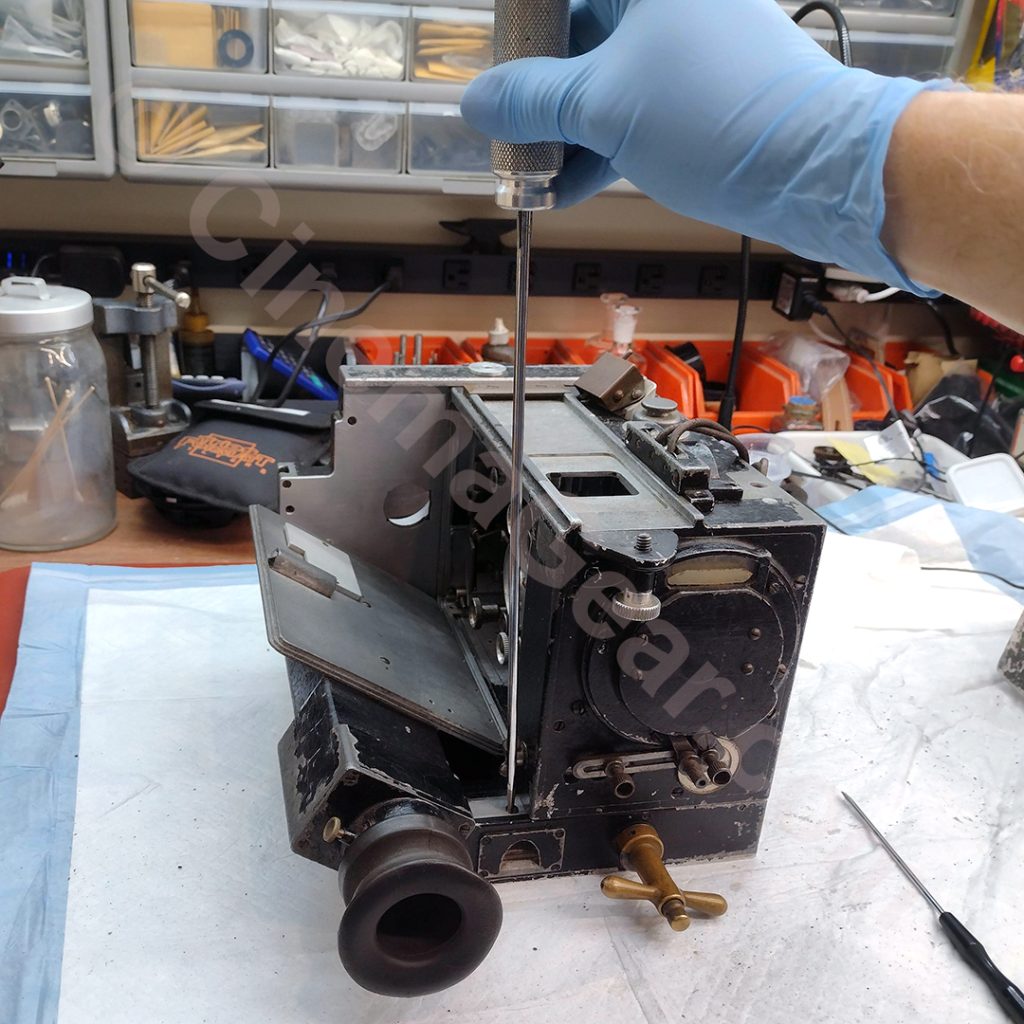

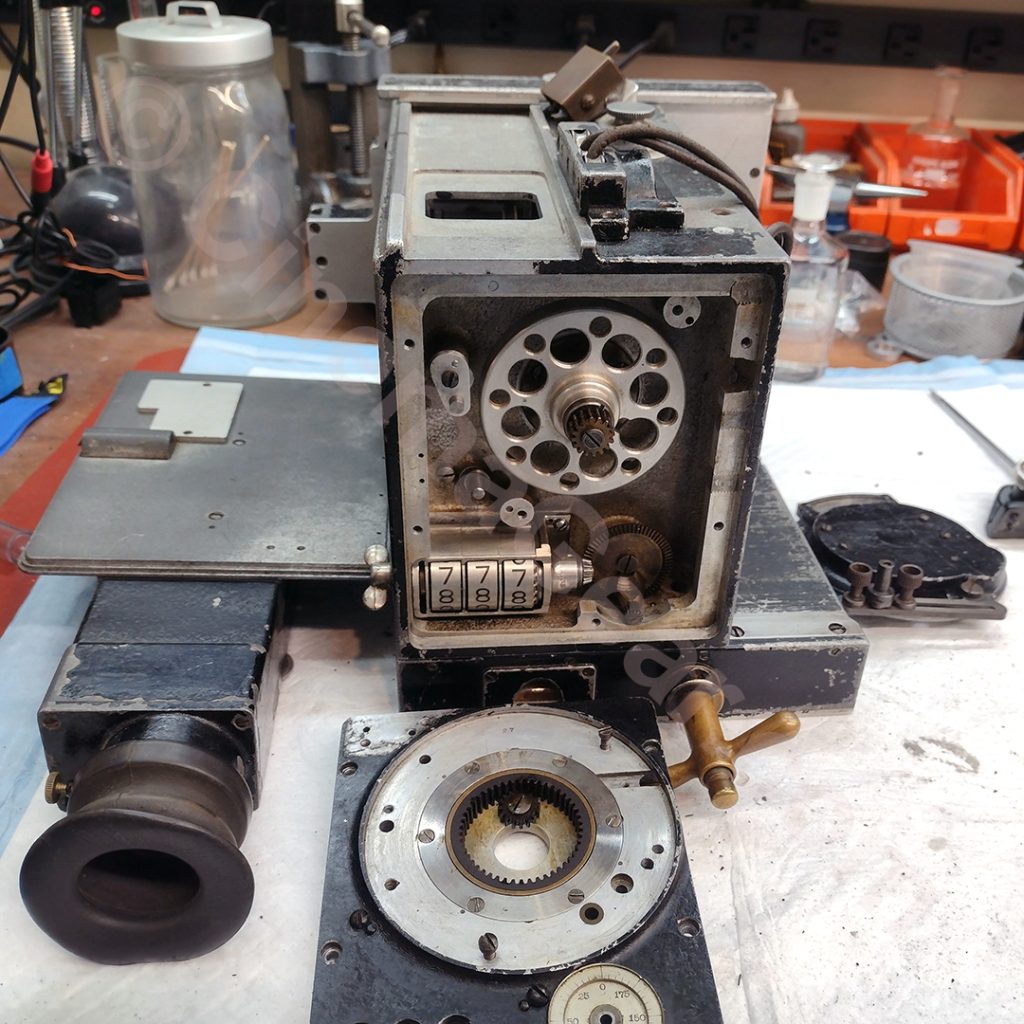

To begin, I cleaned old dirt and grease off both the inside and outside of the camera. I re-lubricated and re-greased all of the moving parts and installed a leather magazine drive belt. Next I realigned the dovetails on the rackover L-base and put the rackover T handle back in time so the camera can sit flat on a table top in either racked over or viewfinding position. When I went to check the timing, I discovered that the arm and gears that adjust the shutter angle were not installed correctly, so I repaired that. This camera was in surprisingly good condition, especially for its age.

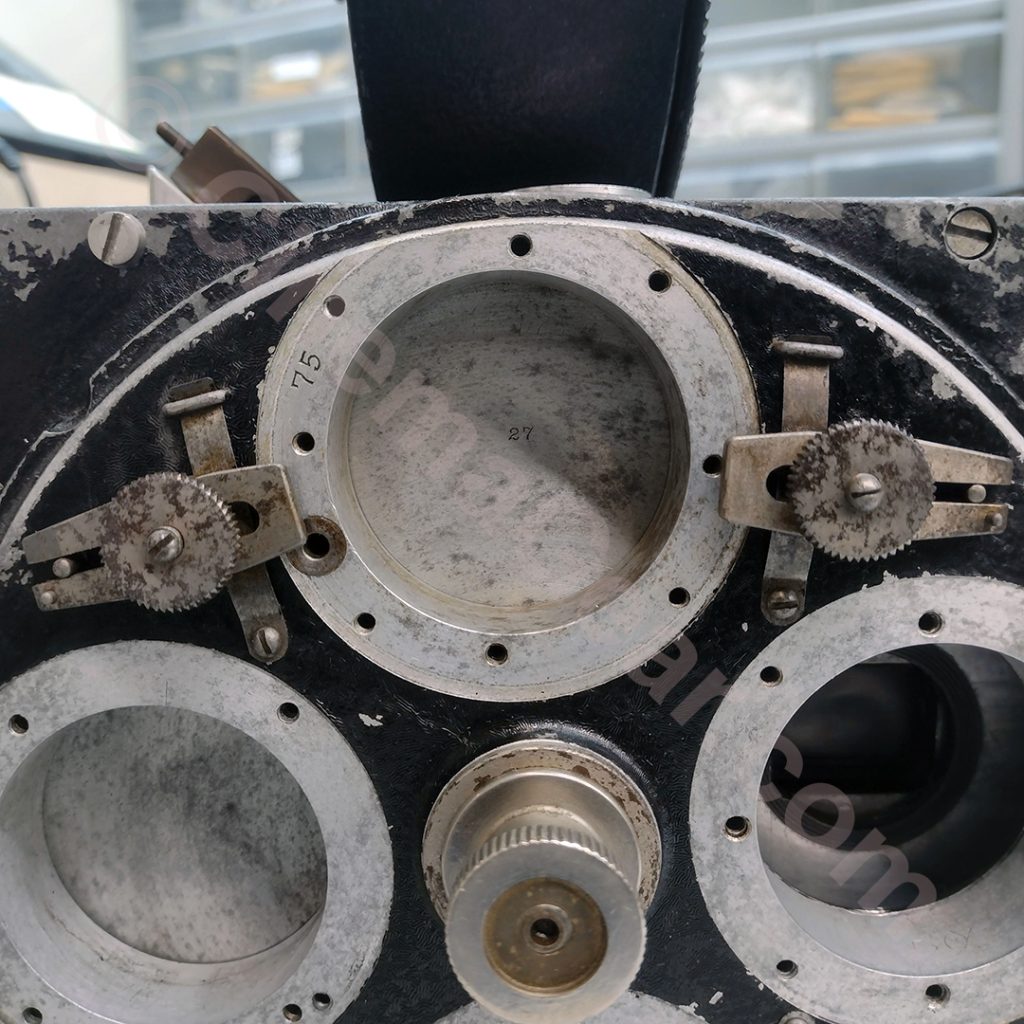

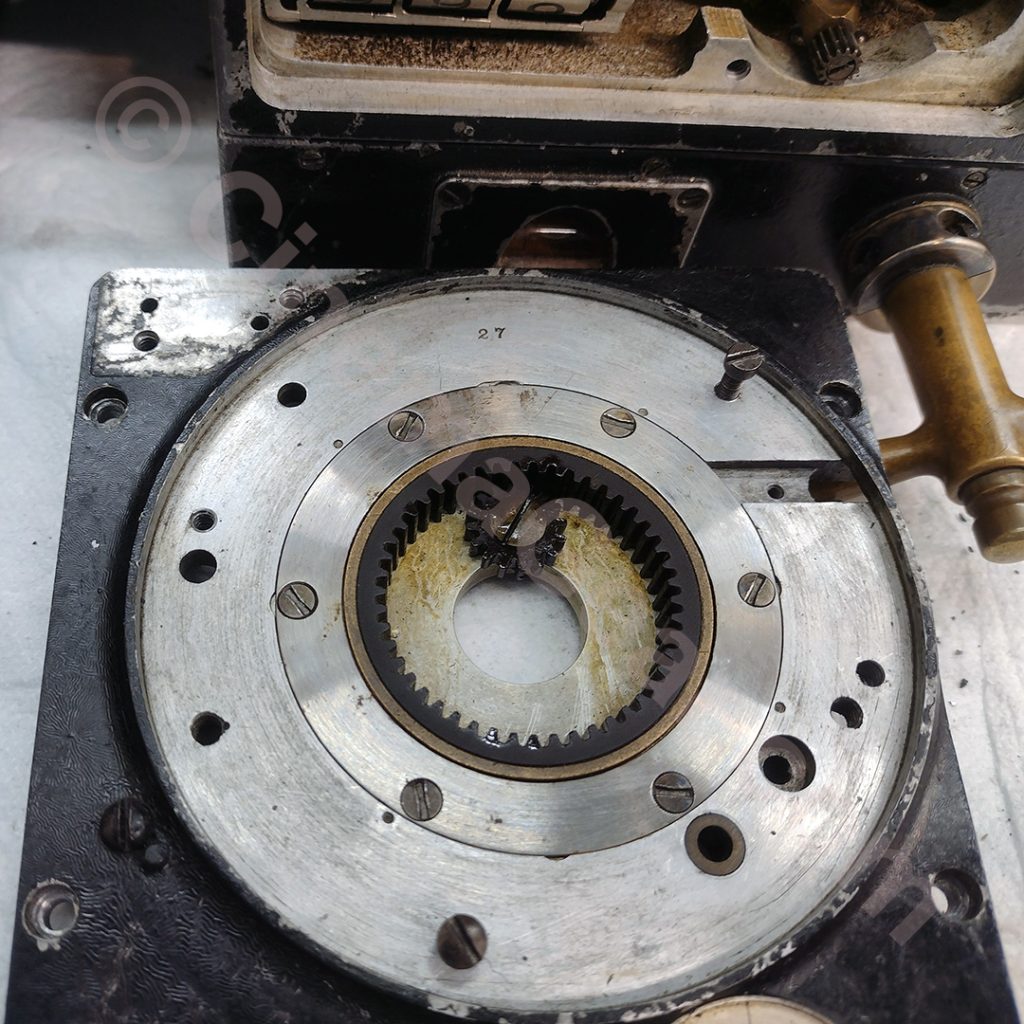

In servicing this camera, it was nice to see that all of the serial numbers matched on all of the numbered parts, including the L-base, the movement, the shutter control assembly, and the flywheel. A few screws had to be tightened, some minor corrosion had to be cleaned off, and the camera itself was once again in prime shooting condition.

The camera also arrived with an original Mitchell 220V AC 60 cycle 3 phase synchronous motor, serial no. 15. The modifications done to this motor suggest that it was paired with this camera at least for its life at MGM. It looks like the studio added buckle switches and modified the power cable so it would work with the Bungalow Blimp.

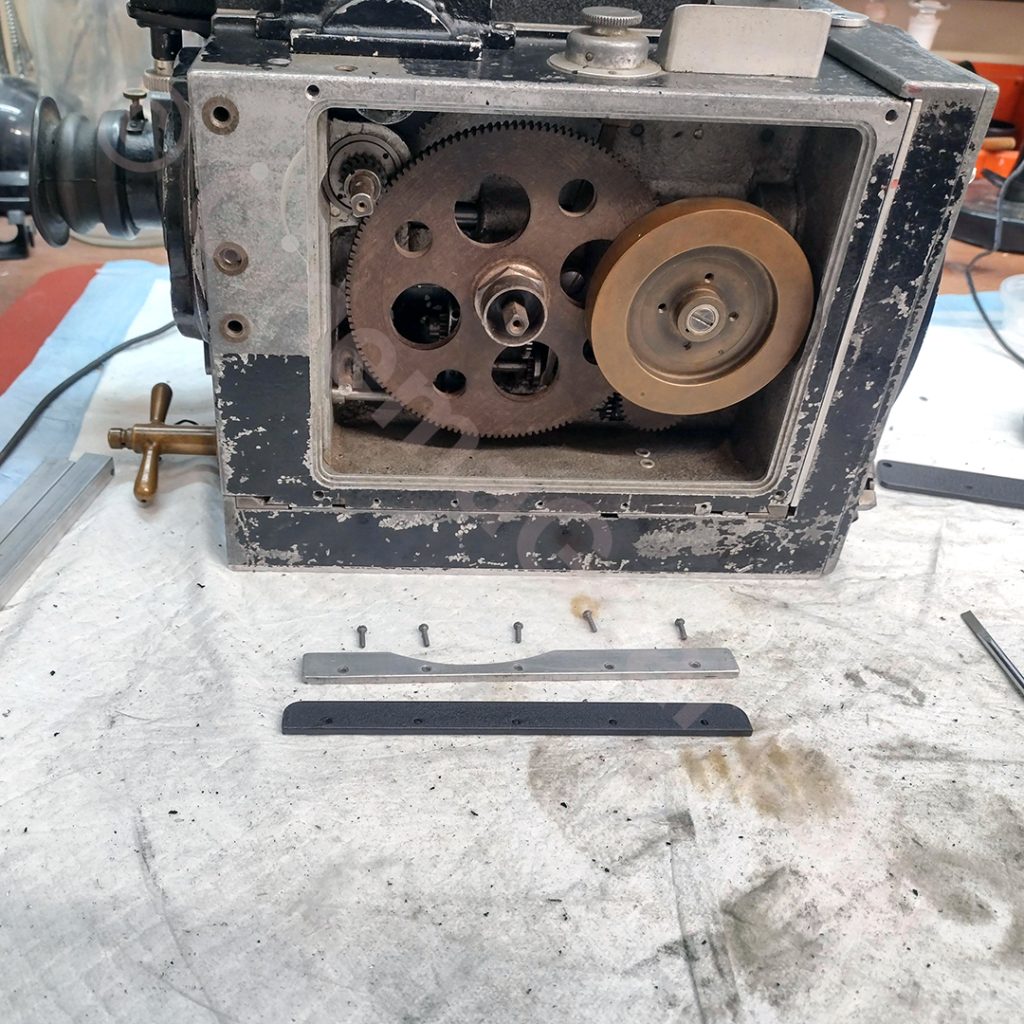

The original motor mounting brackets were missing, so I machined a new set. I wanted to ensure that I didn’t modify or drill any new holes in the camera or the motor, so I had to make sure to use existing holes for both of my new brackets. For the lower bracket, I was able to copy a piece from another camera in my inventory. I had to custom make the upper bracket so it would use holes that were already drilled and tapped in both the camera and the motor.

The motor was also missing the rubber coupling that goes between the camera drive shaft and the motor. Luckily I had a vintage Mitchell rubber coupling in my parts stash. This 220 sync motor was designed to work with the 1:1 drive shaft in the upper left hand corner of the Mitchell Standard and that drive shaft has a D-shape to it. The rubber coupling I had was made to go on a square shaft, so that had to be machined to work with the D shaft.

Once that was done, the rubber coupling was installed on the motor and the motor installed on the camera. I don’t have the ability to run the 220V 3 phase motor, but everything inches by hand smoothly. It’s always a pleasure to breathe new life into these cameras and I was glad to bring Mitchell Standard no. 27 back to working condition.