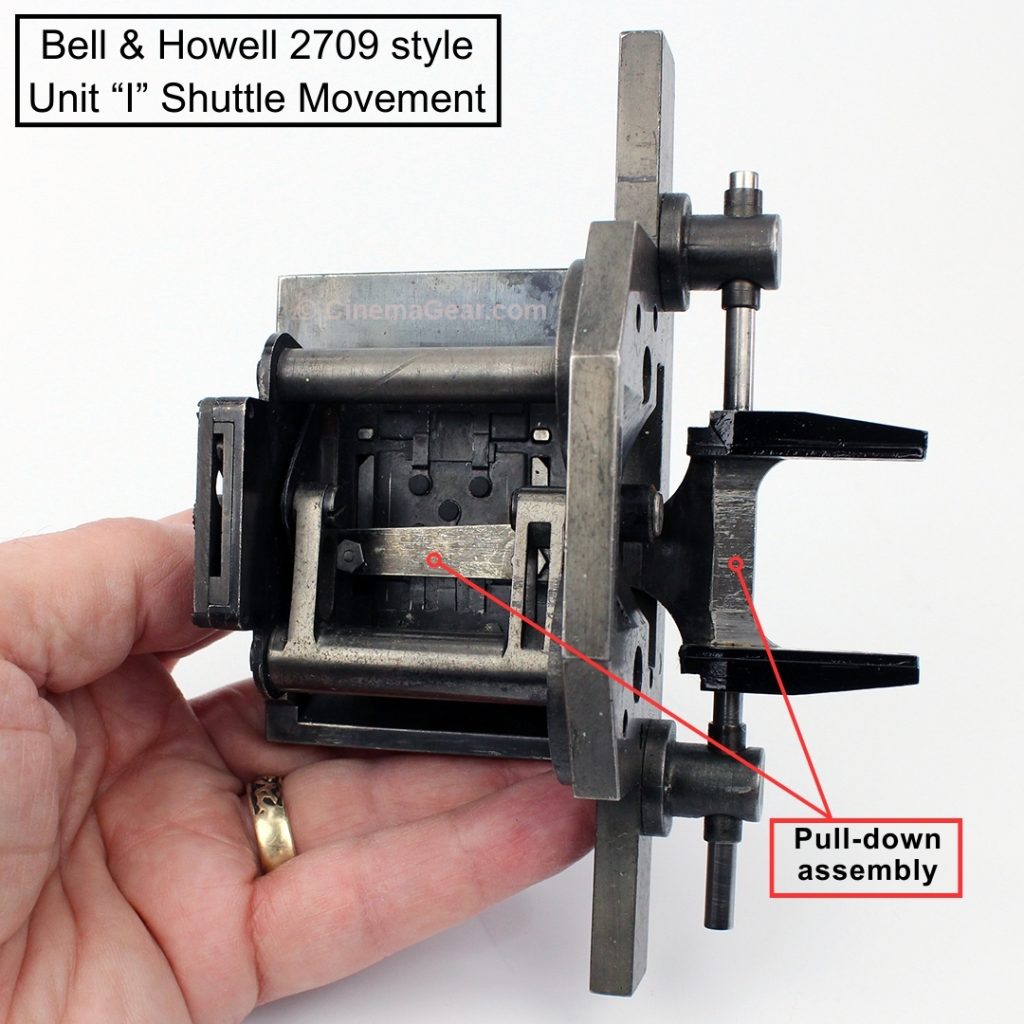

Over the last few weeks, I have had a few people ask me about optical printers, scanners, Bell & Howell cameras, and Acme cameras. Sadly the revolutionary technology behind these machines is slowly being forgotten. At the heart of these machines is the film transport called the Unit “I” Shuttle. The unique design of this movement ensures the best possible film registration, and was the standard of the trade for decades. I thought I would take a moment to show you a few of the basics of the Unit “I” Shuttle movement and its evolution.

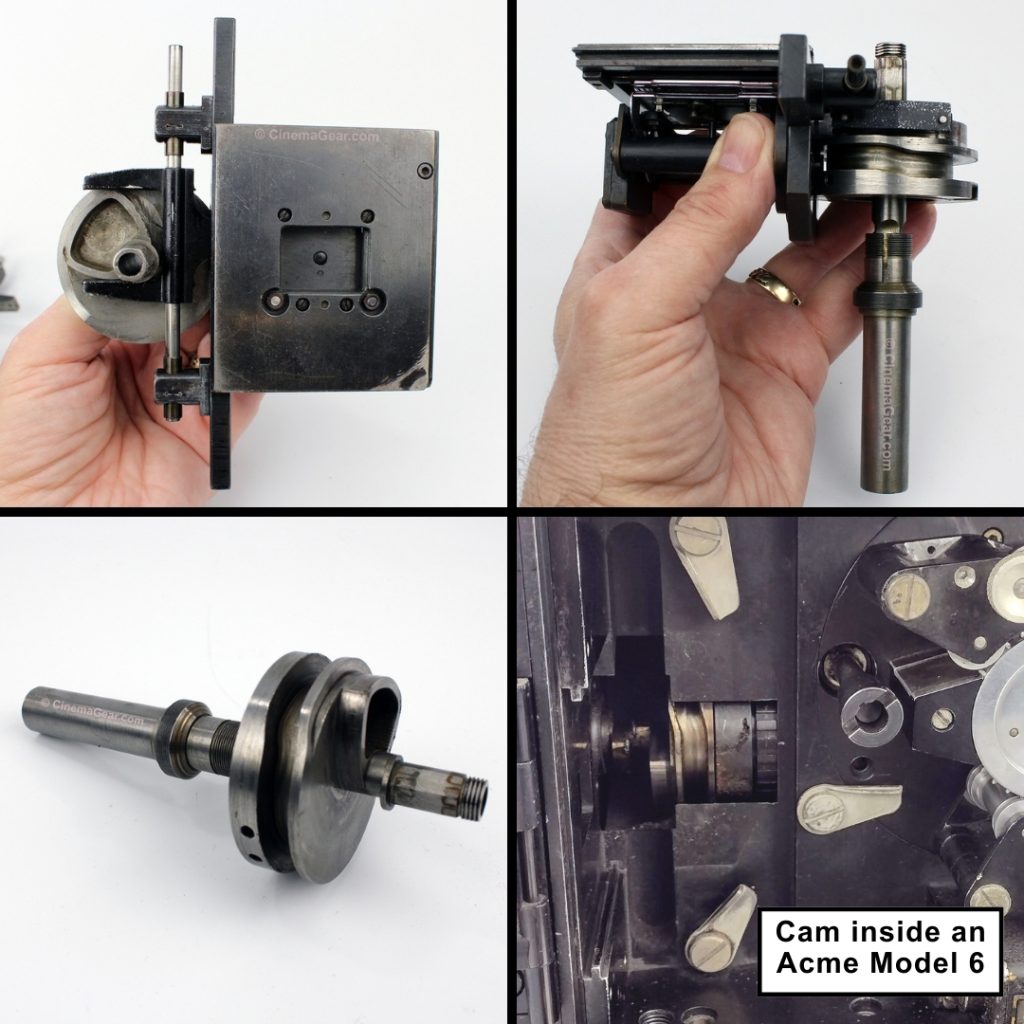

Unlike many of the other film transports, the registration pins on the Unit “I” Shuttle are in a fixed position in relation to the aperture, so every time film is moved, it registers exactly the same from frame to frame. The movement is operated by an ingenious drive shaft that is made up of a cylindrical guideway cam that operates a follower on the movement to pull the film on and off the registration pins. It also has a heart-shaped (cardioid) cam that engages the pull-down fork to advance the film from one frame to the next.

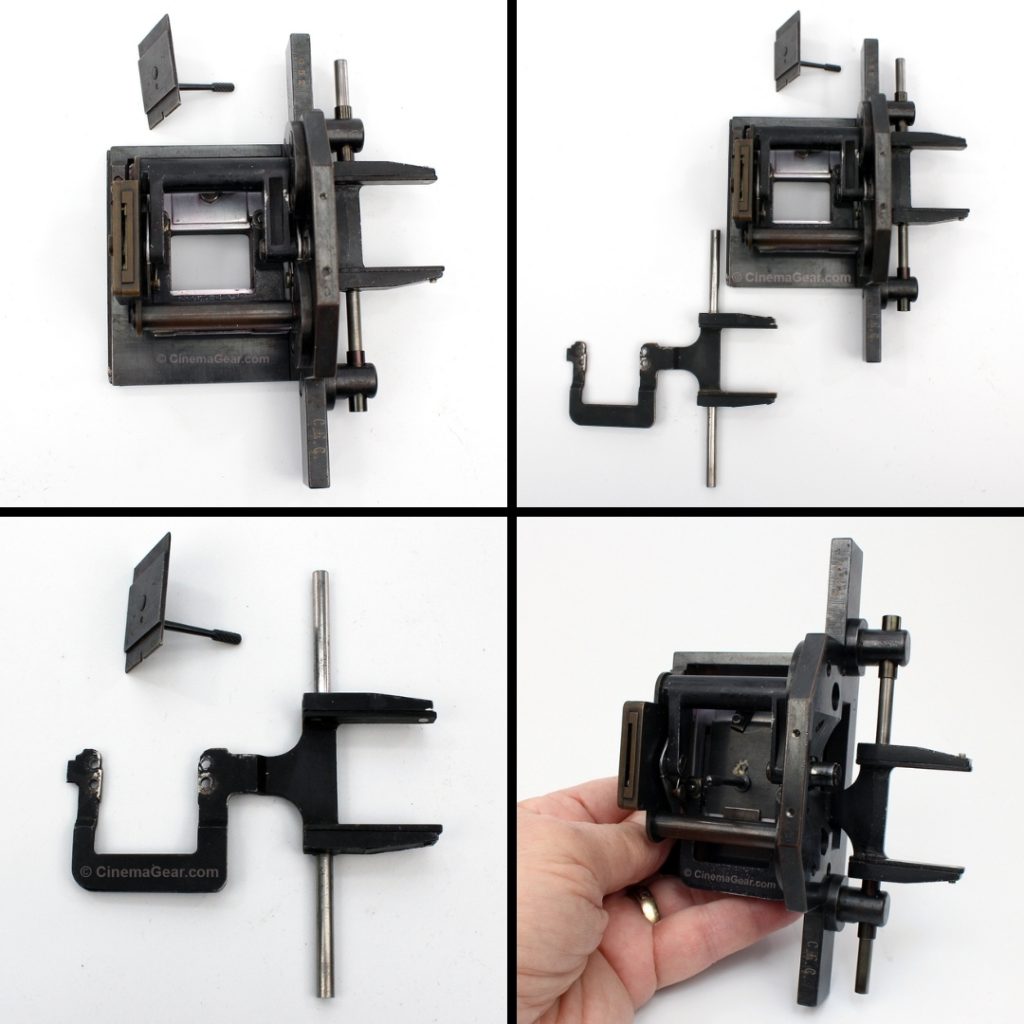

In early examples of the Unit “I” Shuttle, the pull-down claw mechanism is a straight bar that crosses the film path as film is advanced from frame to frame. These movements also did not yet have a removable pressure plate. As rotoscope and optical printing became more commonplace, these aspects of the early movements made it difficult to view or project through the film plane. Some early adopters of these processes simply cut a big chunk out of the pull-down and cut a hole in the backing plate of the movement so you could see through the film plane. An inelegant, but effective solution.

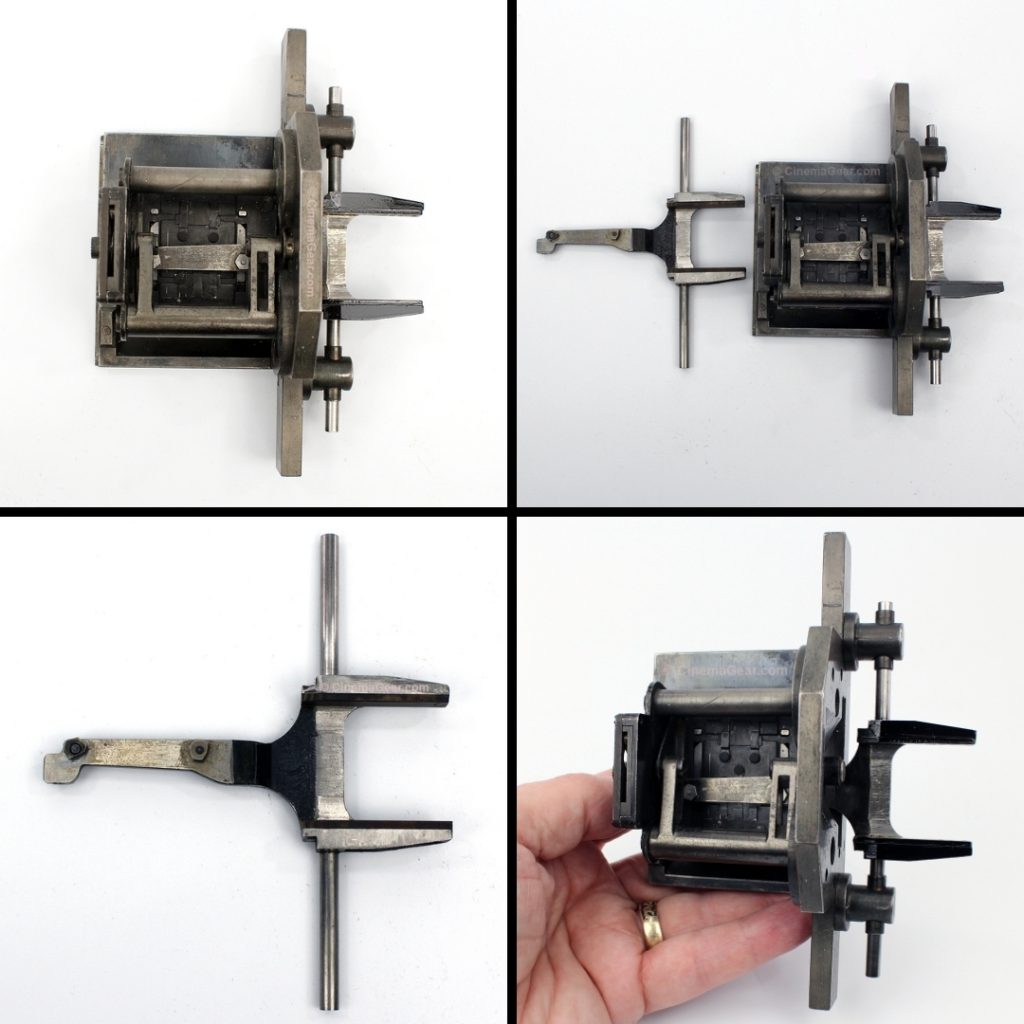

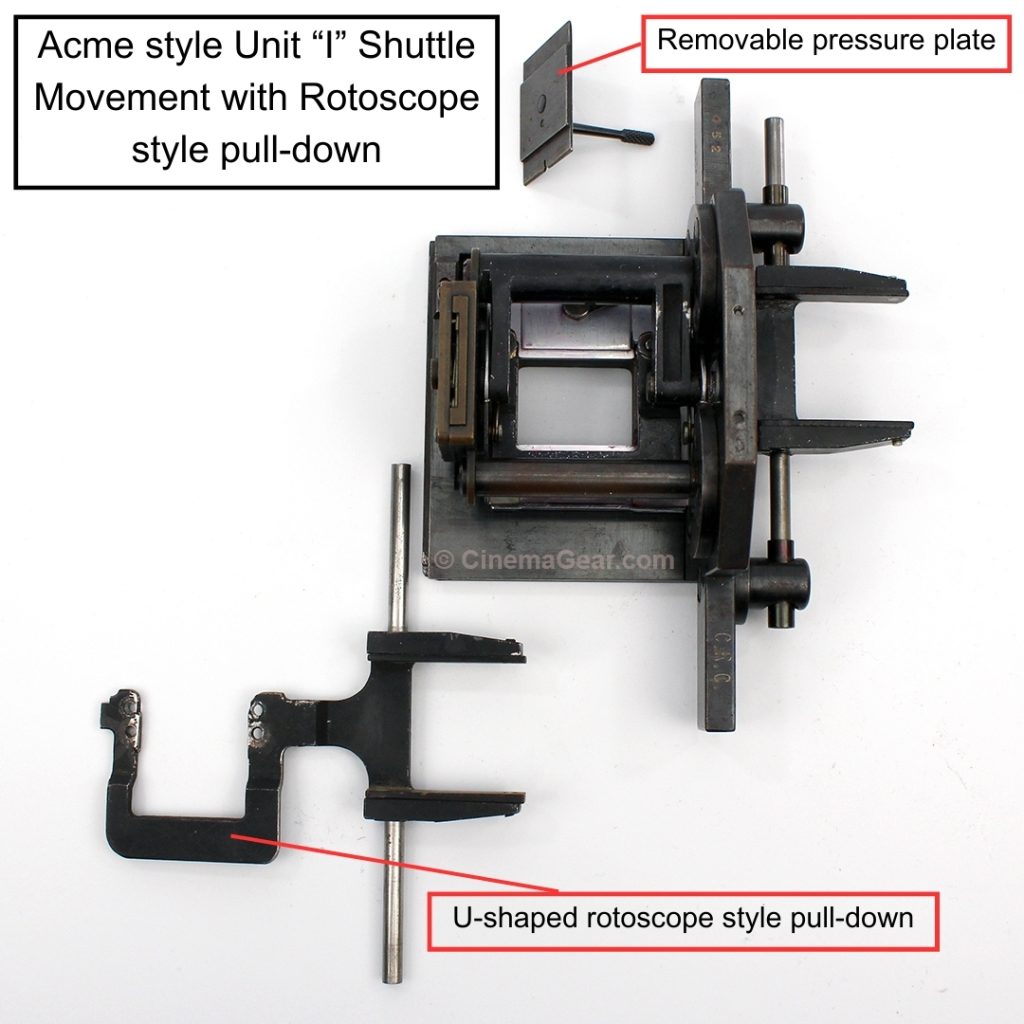

As the Unit “I” Shuttle movement evolved, manufacturers took these homebrew solutions and introduced the rotoscope style pull-down assembly and removable pressure plates that made these processes more user friendly. In these newer versions of the Unit “I” Shuttle, like those manufactured by Acme and Oxberry, the pressure plate was made to be easily removable. The pull-down claw took on the unique U-shape so it never interfered with the film path. These innovations allowed for better lineup during the rotoscope and optical printing processes. As patents expired, a number of companies manufactured Unit “I” Shuttle movements, but they all had essentially the same form and function.