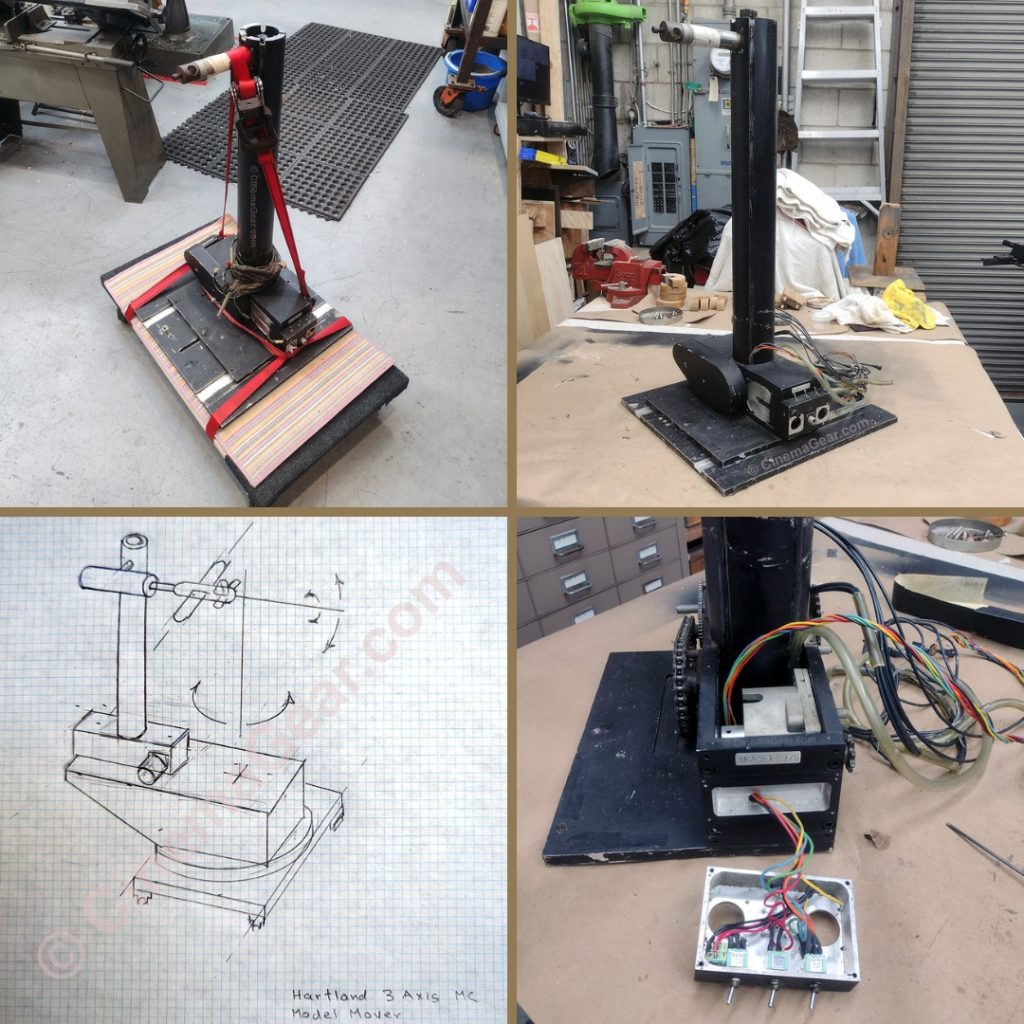

Some 40+ years ago, I had the privilege of being one of the engineers and cameramen at the Universal Studios Hartland visual effects facility. One of the many things I designed and built there was a 3-axis motion control model mover. My friend Peter Anderson rescued part of one of these model movers and kept it in his collection for lo these many years. As you have seen in several of my other posts, I have been involved in an ongoing project doing restoration of the Dykstraflex motion control camera crane for the Academy of Motion Picture Arts and Sciences. In preparation for the upcoming May the 4th Celebration: Across the Galaxy at the Academy Museum, I was asked to repair what is left of the model mover so it can be included in the display of the Dykstraflex as an example of some of the many motion control model moving devices of that era. In its original configuration, this model mover had 3 axes: pitch, yaw, and roll. The axes could be adjusted so the nodal point of the miniature was at the nodal point of the model mover. Sadly, only the proof-of-concept roll axis and the main mast have survived.

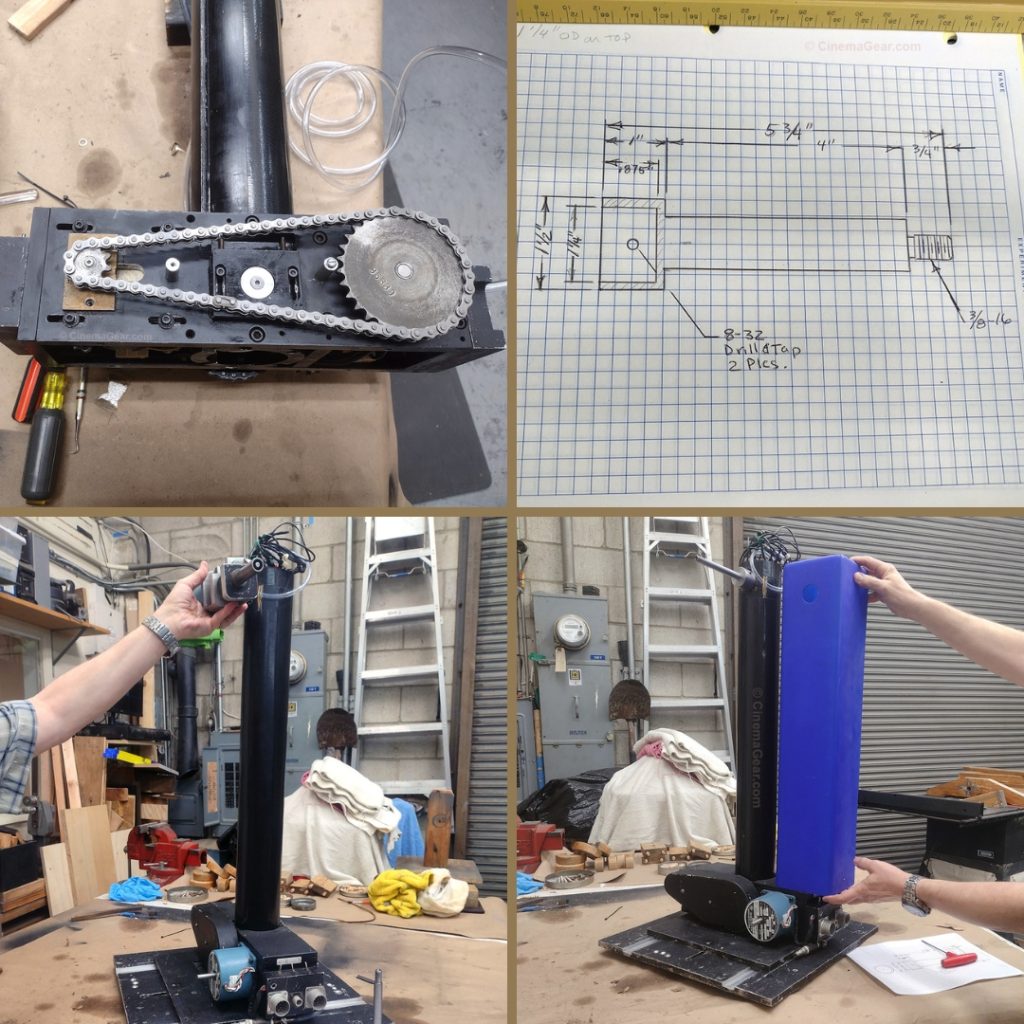

When Hartland closed, this model mover went on to many more years of service at other production facilities. During this time, it was used, altered, abused, and then left in storage for a long time. In an attempt to bring it back to as close to original condition as I could, I replaced the stepper motor with a vintage stepper motor, replaced one of the missing roller chains, replaced the broken mechanical counter, lubricated everything, and got the main mast working again. Somewhere in its life, an oversized drive shaft was forced into the upper collet assembly and, no matter how much pounding, heating, and penetrating oil I applied, I couldn’t get the drive shaft out of the upper collet assembly. The decision was made to cut the shaft off fairly close to the main mast and make an adapter so the main mast could work like a roll access. Next week I will fit the backlit blue screen pylon on the mover, and in that condition, it can be used like a roll axis. I will show you that configuration in my next post.