Amongst the remarkable antique camera haul I shared with you a couple of weeks ago was, what at first glance, looked like a very gently used Auricon tripod with friction head. When we pulled the tripod out of its shipping tube, it had been disassembled, the legs separate from the pan tilt head. At this point I noticed that the top part of one of the legs was broken off.

Even with this broken leg, the tripod still appeared in extremely nice condition with very few signs of wear and tear. The break on this leg was so clean, I could literally fit the pieces back together nearly seamlessly. How this came to be broken, I am not sure, but I was determined to fix it if possible.

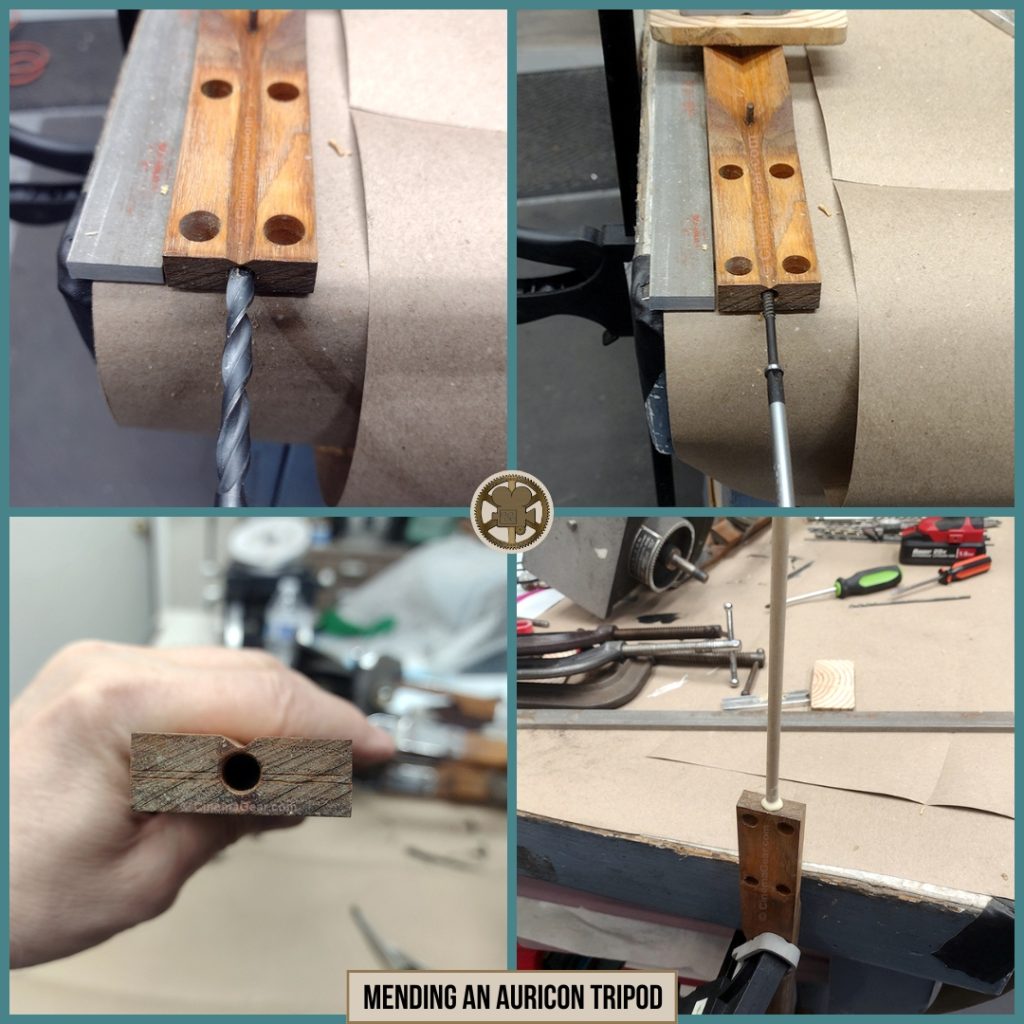

People keep telling me that the modern wood glues are stronger than the wood itself, so since the pieces fit so neatly back together, I applied a generous amount of wood glue and clamped the leg along its length and across its face while the glue dried. Being inherently skeptical of the “stronger than the wood itself” claim, once the clamps were removed, I pulled a 3 inch long wood screw out of the hardware collection, and turned the head of the screw down to a smaller diameter so the counterbore I had to drill in the top of the leg would be as small as possible. Once the counterbore was established, I drilled a pilot hole through the top of the leg and into the main body of the leg.

Once the screw was installed completely, I cut a wooden dowel and glued it into the counterbore hole, figuring if the “stronger than the wood itself” claim was true, this would return the leg to its original strength.

I let everything set up for another day so I was sure the glue had completely cured everywhere, and at that point, I could no longer tell that the leg had ever been broken. Between the glue and steel screw, I am confident that this tripod is now as good as new. Now to pick an Auricon camera to sit atop it . . .