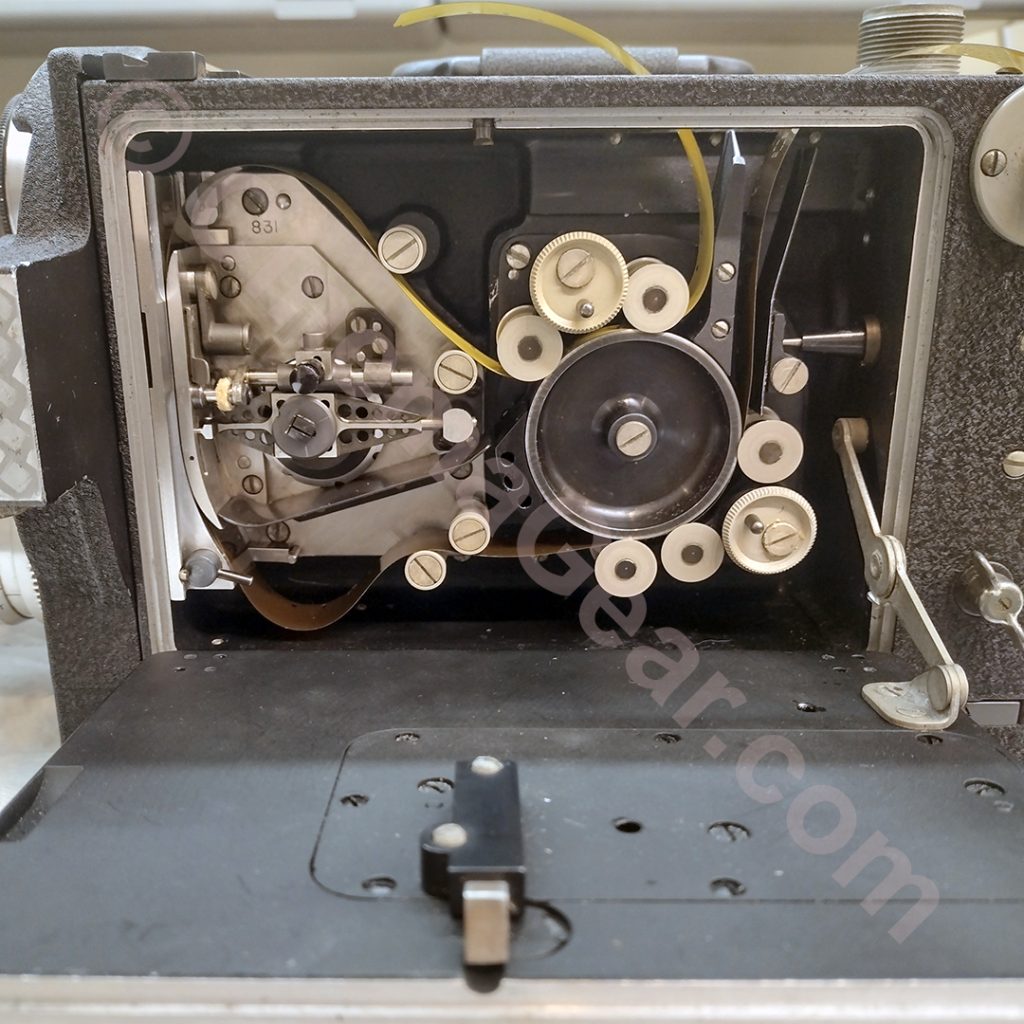

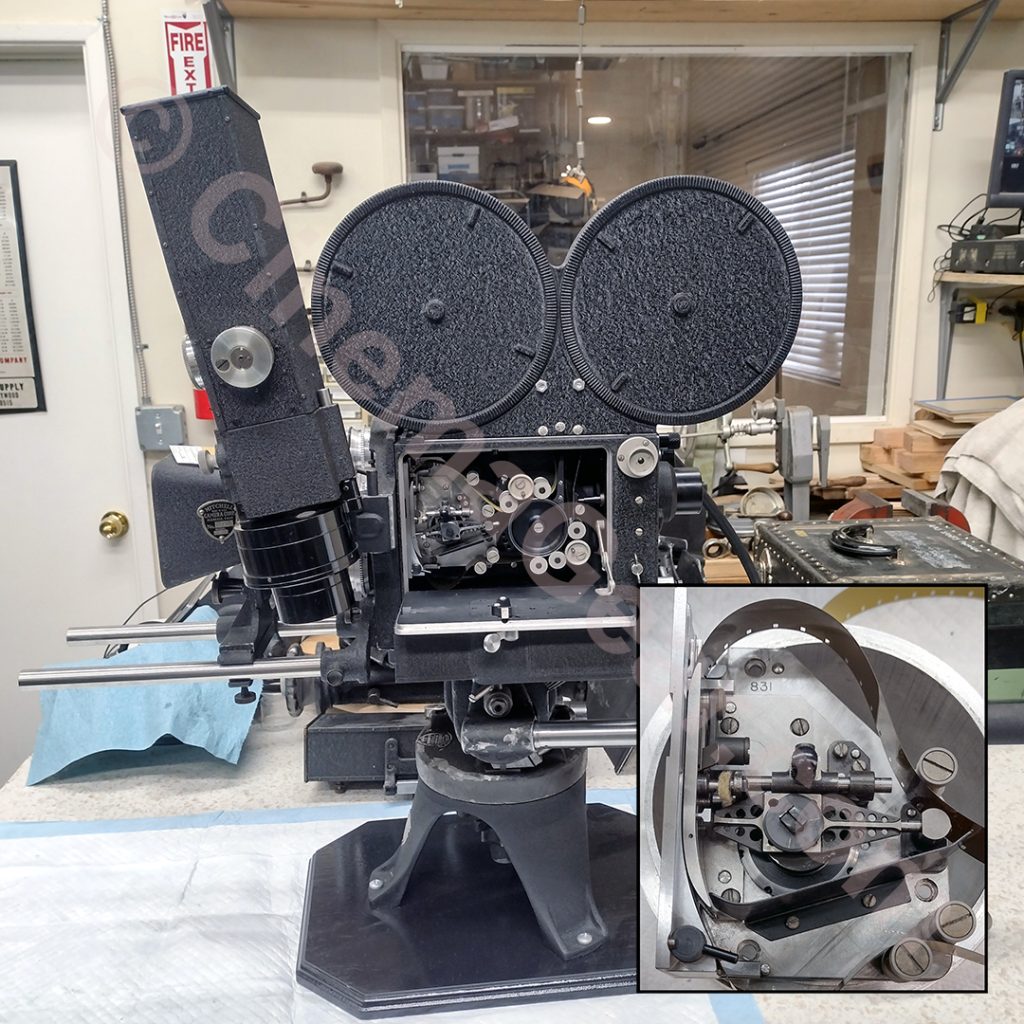

A few weeks ago, an up-and-coming cinematographer wrote to me and asked if I had any 16mm animation cameras. He was planning to shoot a table top animation short subject. As I don’t currently have any 16mm Acme or Oxberry cameras, the next camera that came to mind was this lovely 16mm Mitchell Pro. The Mitchell 16 Pro has excellent registration, a fair amount of accessories, and is very well suited to the table top animation he is looking to do. The issue with the Mitchell 16 Pro is that it was designed to shoot double perforated 16mm film, and double perforated 16mm film is very difficult to find in today’s world. I hate to cut up a camera, but in this case, it would guarantee that this camera would go on to make more movies. So I set about to modify the pull down claw and registration pin assemblies in this camera to work with single perforated 16mm film.

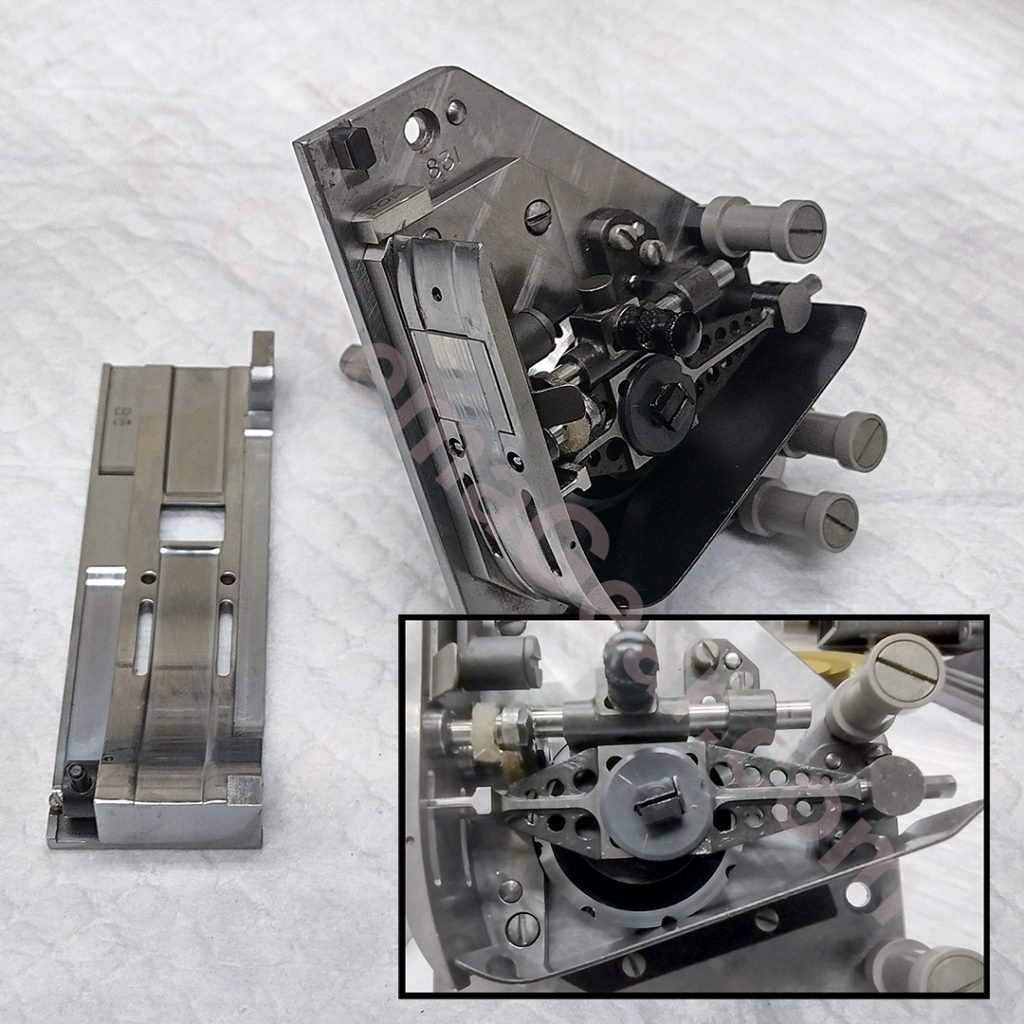

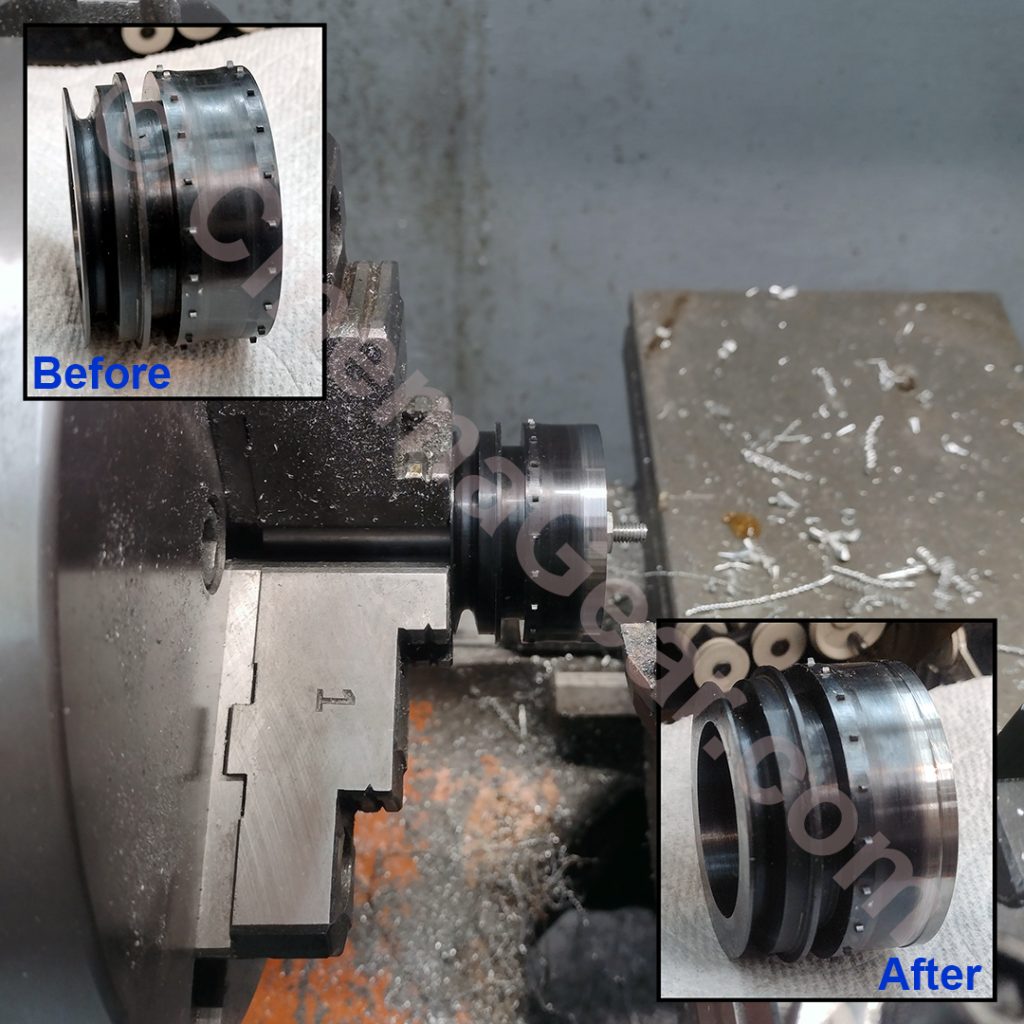

A couple of important things to take into account when modifying a Mitchell movement: First, the registration pins are lapped and fit to go through a pair of hardened bushings, so you can’t just remove one of the pins. It is best to remove just the part of the registration pin that engages the perforation in the film, leaving enough of the body of the registration pin so that it still engages with the bushing. The pull down claw is a little simpler, as it’s held in alignment to the film by the cam that moves it through the pull down cycle. Sadly, you have to cut the outboard pin off of the pull down claw assembly so it operates with single perf film properly and without causing damage. Lastly, you have to machine the outboard teeth off the sprocket and polish the surface where the teeth once were so the picture area of the film is unaffected. The camera was then reassembled, re-timed, and re-lubricated so it is ready to make more movies. I hope this modification keeps this camera in use for many more years.

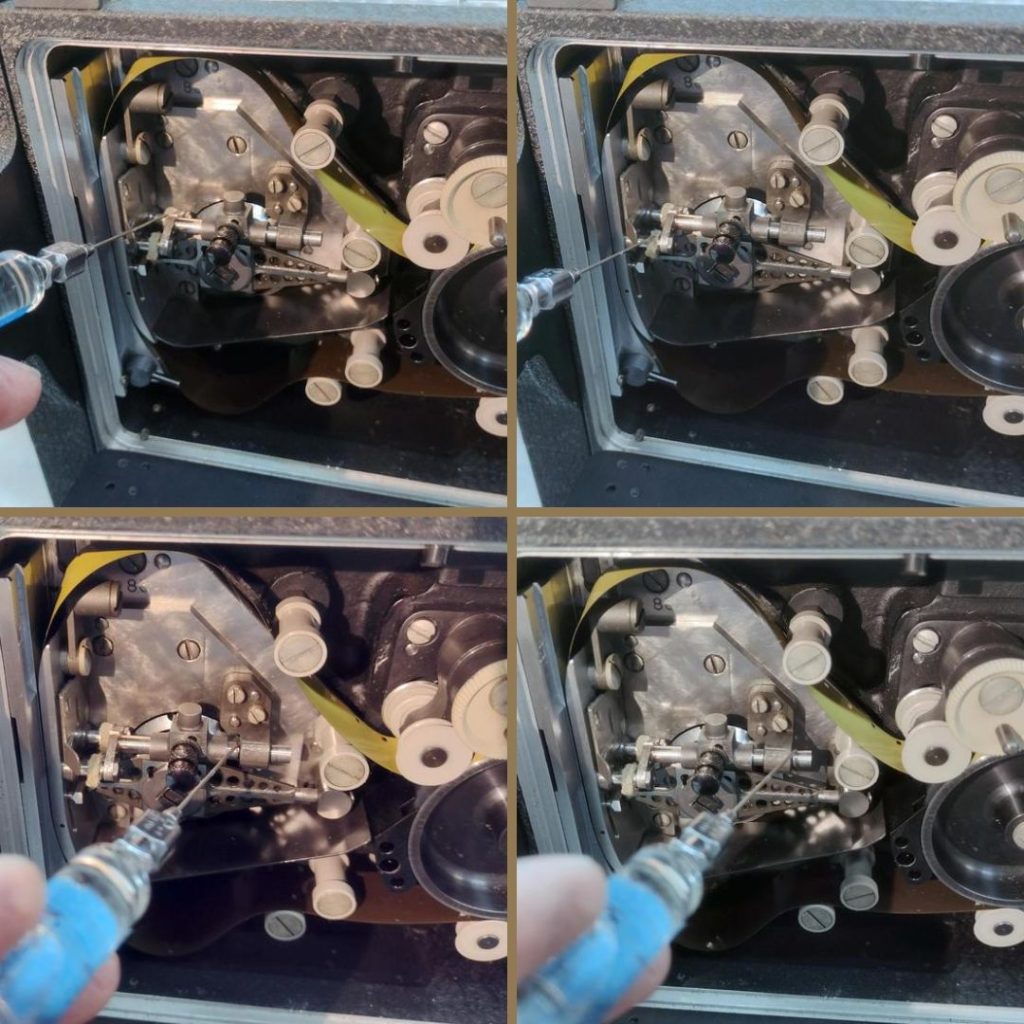

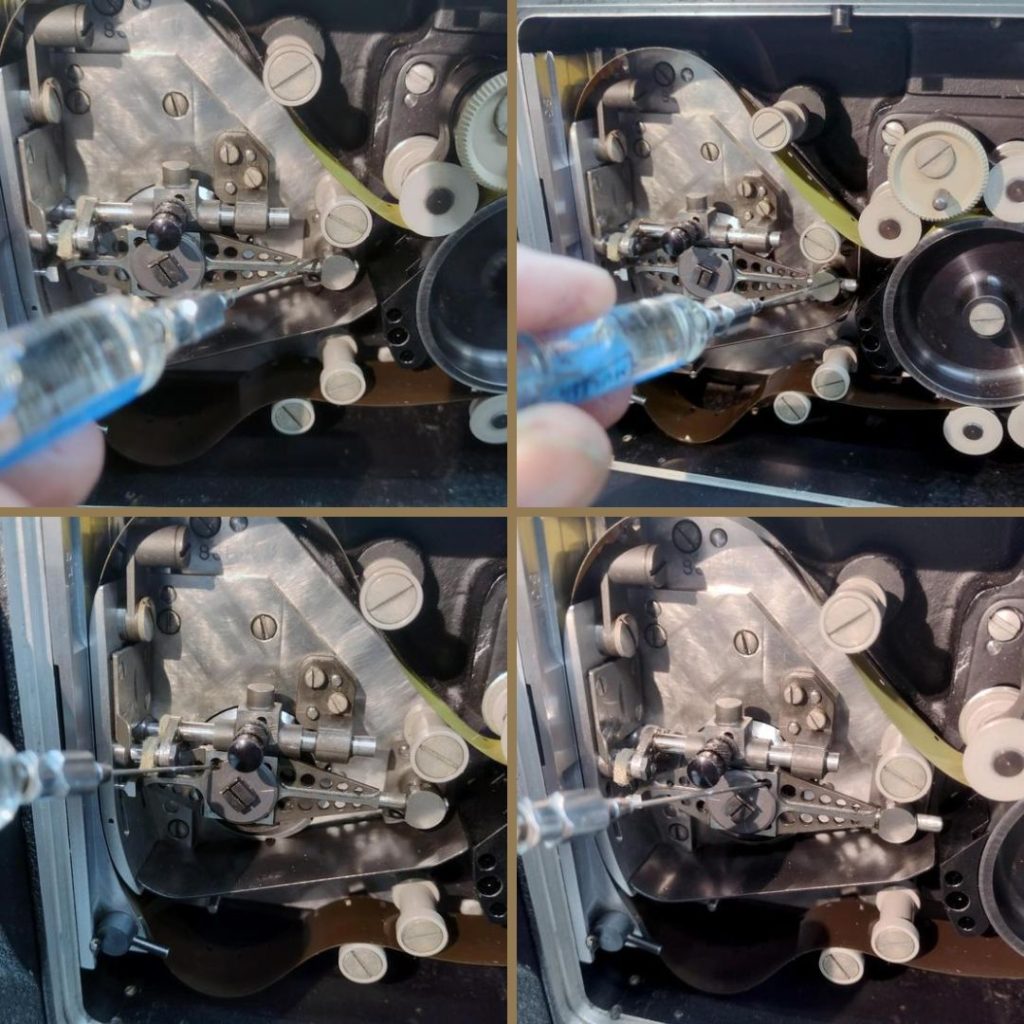

While I was reassembling and relubricating the movement, I thought I would share the oiling procedure for the Mitchell 16 Pro. Most of the bearings internal to the camera are sealed, permanently lubricated bearings. However the movement needs to be oiled regularly. Special attention needs to be paid to the registration pin oil pads to make sure they are fully saturated with oil, but not dripping. Next would be to put a drop of oil on the front and the back of the registration pin shaft. This should be followed by putting a drop of oil in the front and the back of the pull down claw shaft. Lastly, a drop of oil in the top two corners of the pull down claw cam. If I were setting up to shoot, I would also pull out the gate, make sure the aperture is clean and there is no emulsion build-up on the gate, reinstall it, and load film. That has been my practice with all the Mitchell cameras I have used as the daily maintenance.