While I had the movement out of a Mitchell GC, I thought I would demonstrate the lubrication points on the movement for those who have never worked with one of these cameras.

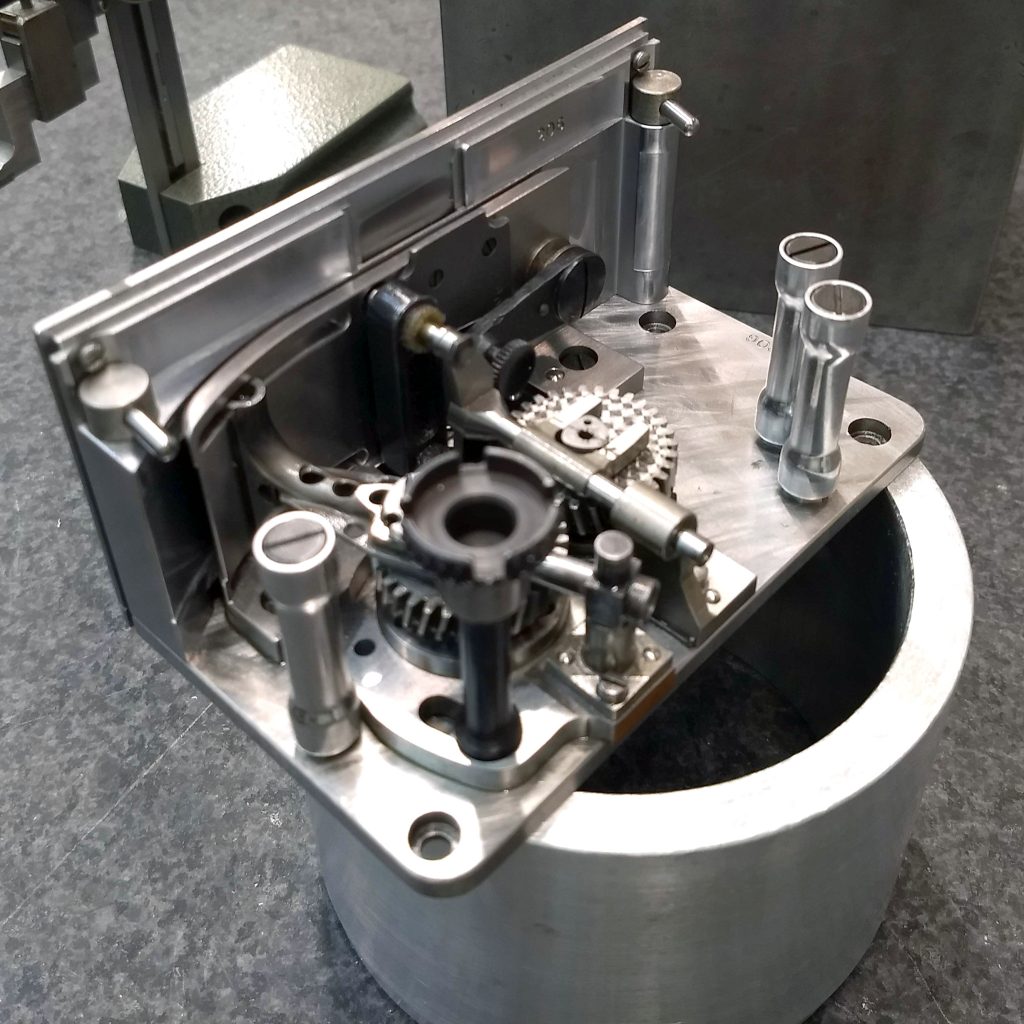

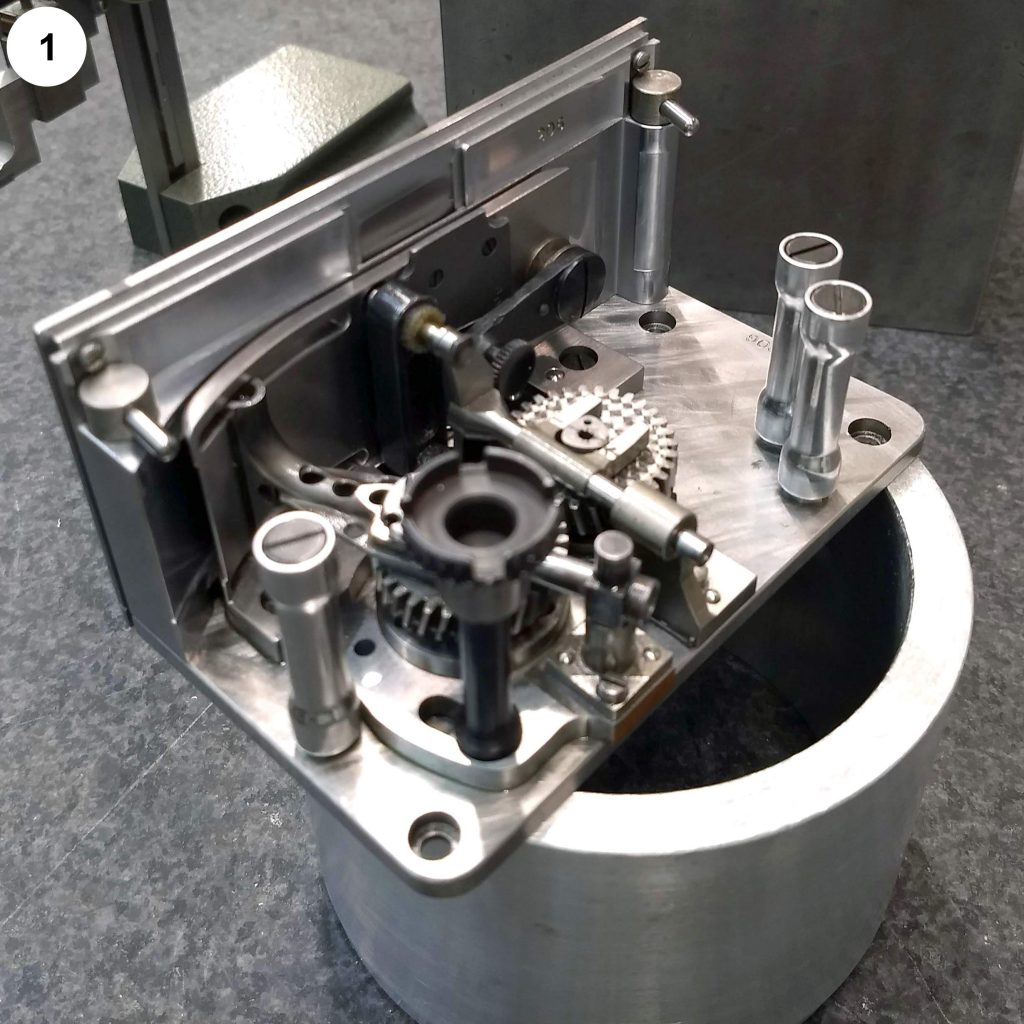

1. Movement removed from camera

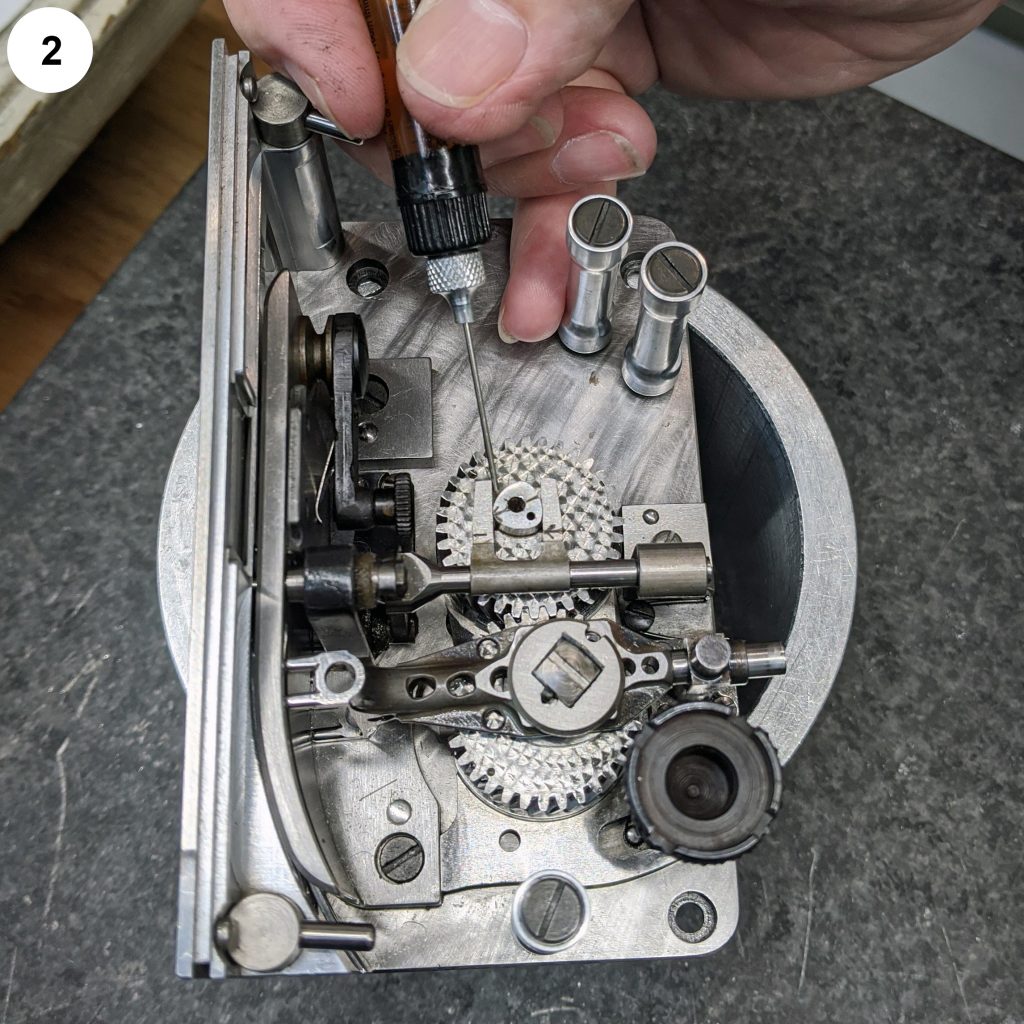

2. Working from top to bottom, 1st is the cam that operates the registration pins. A drop of oil on both sides of the cam opening is the best procedure.

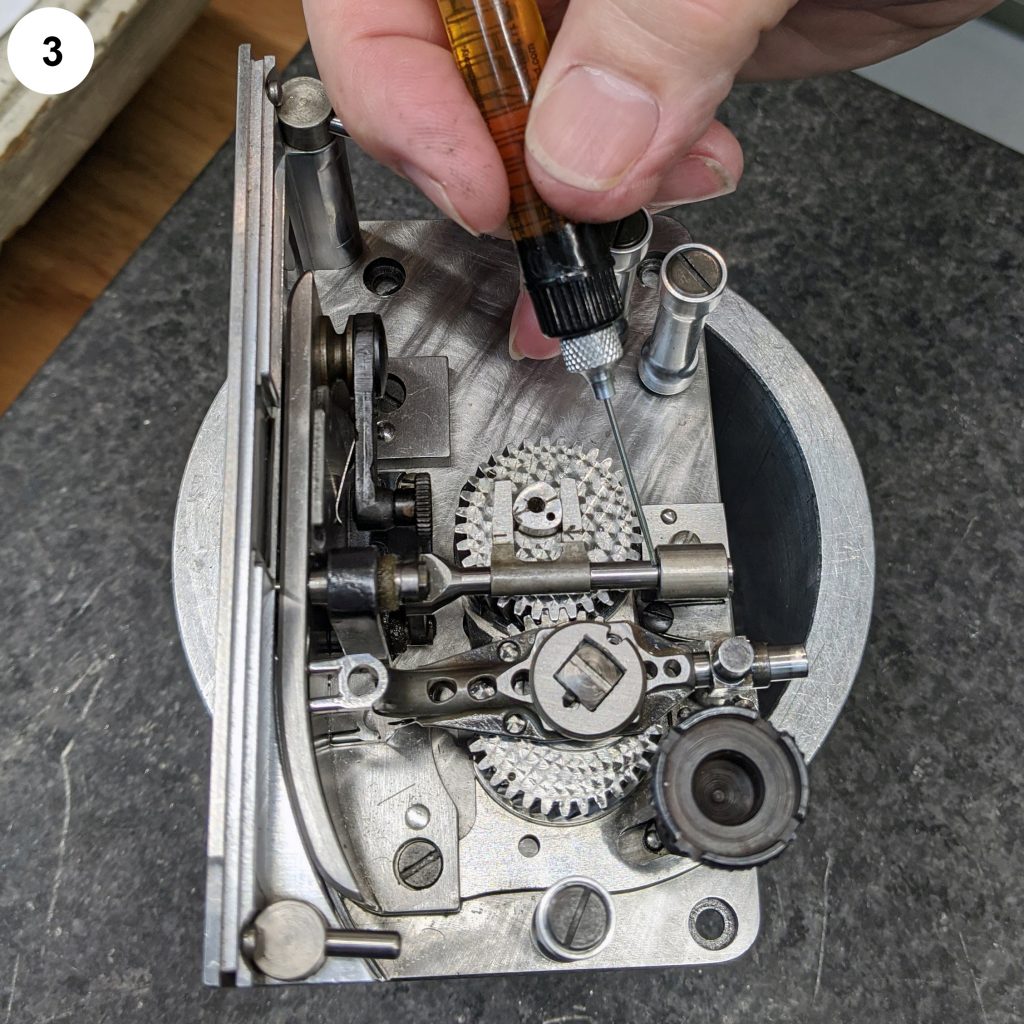

3. The bearing block that supports the back of the registration pin assembly gets oiled at the front and back of the shaft that the block supports.

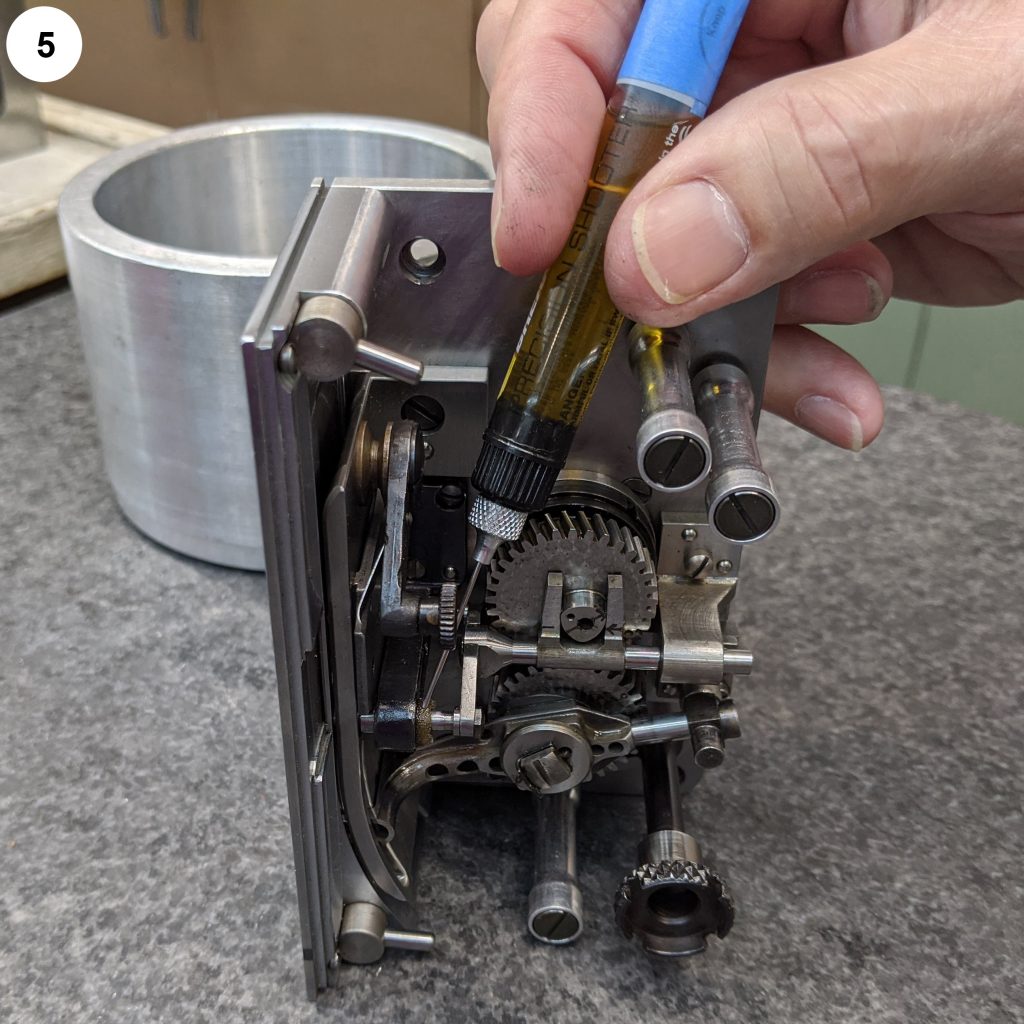

4. & 5. There are 2 felt oil pads that keep the registration pins lubricated as they go through the guide bushings and engage the film perforations. These pads need to be saturated so they take on the color of the oil, but not oversaturated. 4 shows the inboard oil pad, and 5 shows the outboard oil pad.

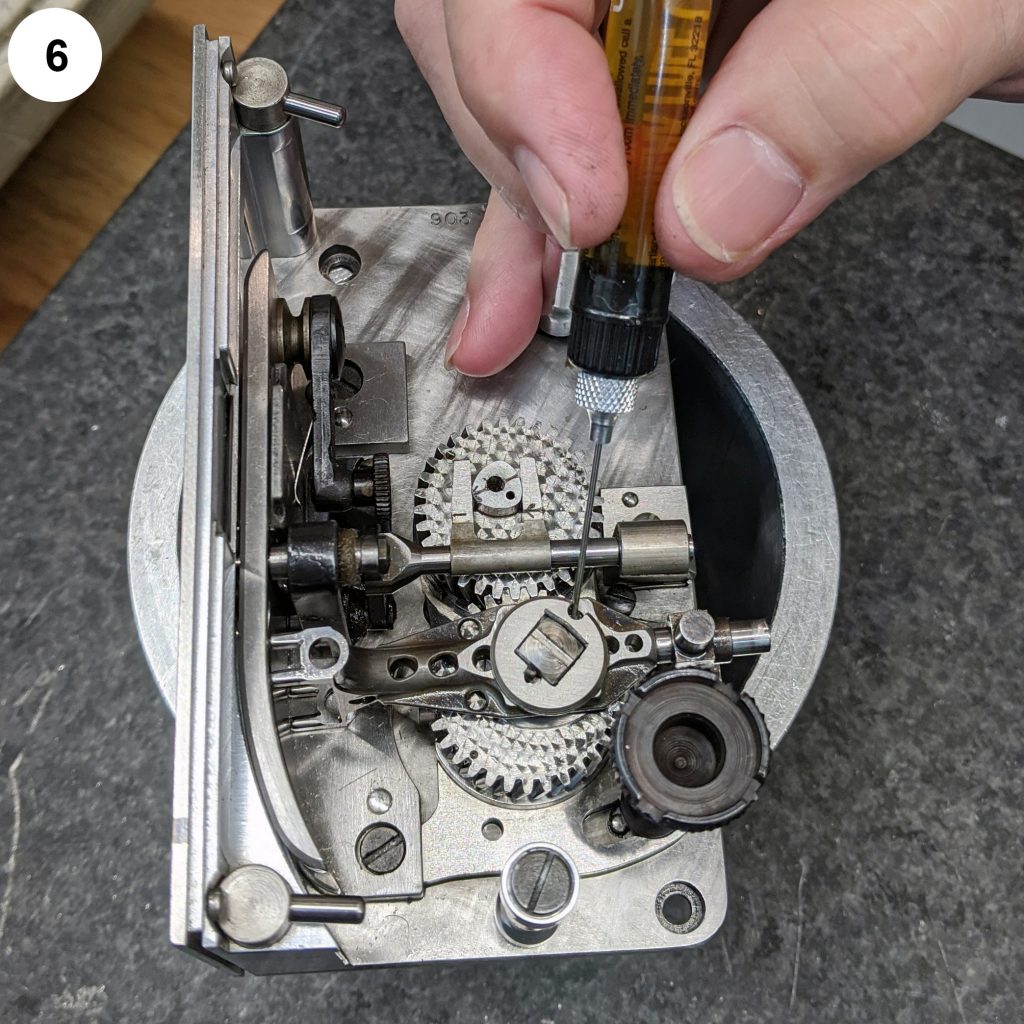

6. The pull-down claw cam is kept in place by a thrust plate. A notch in the outside diameter of the thrust plate lets a drop of oil be placed in the 2 upper corners of the cam. It is important to put a drop or oil on the left and right upper corners to ensure oil circulation.

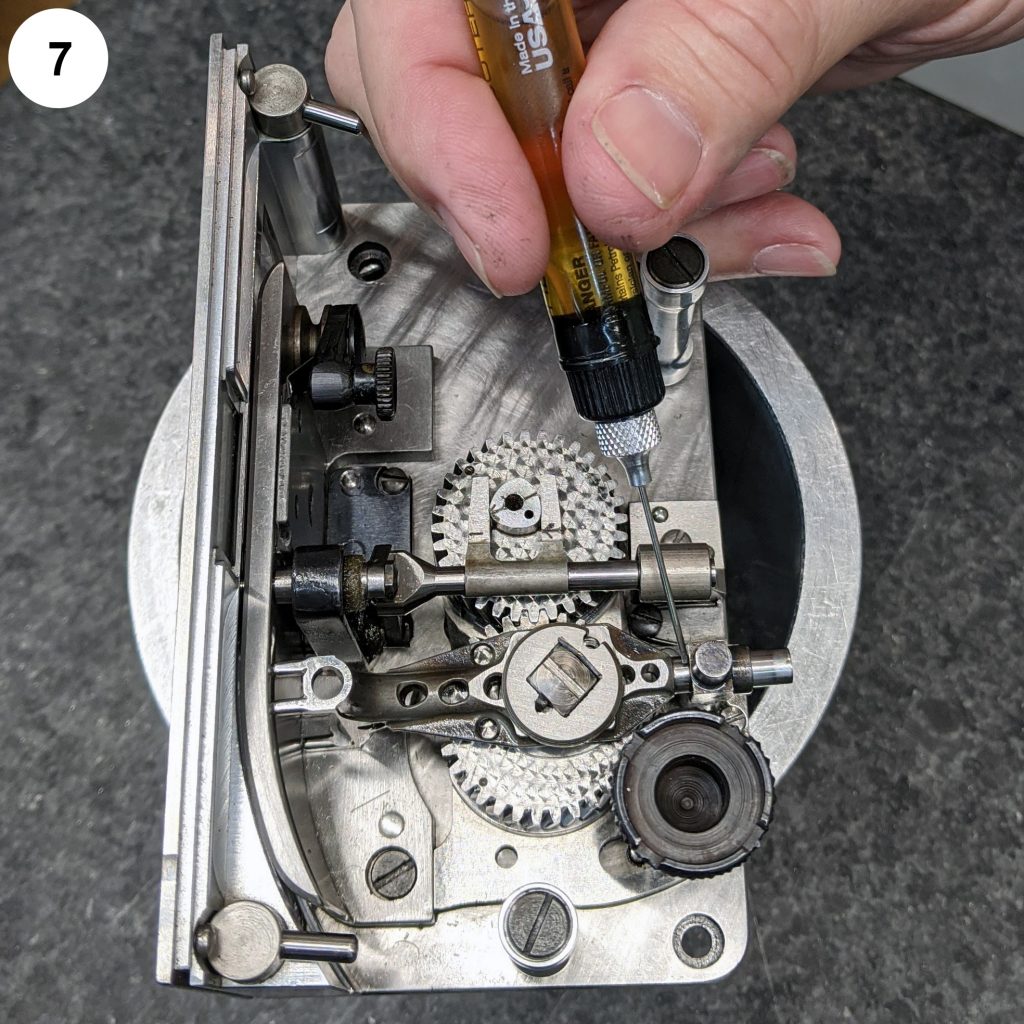

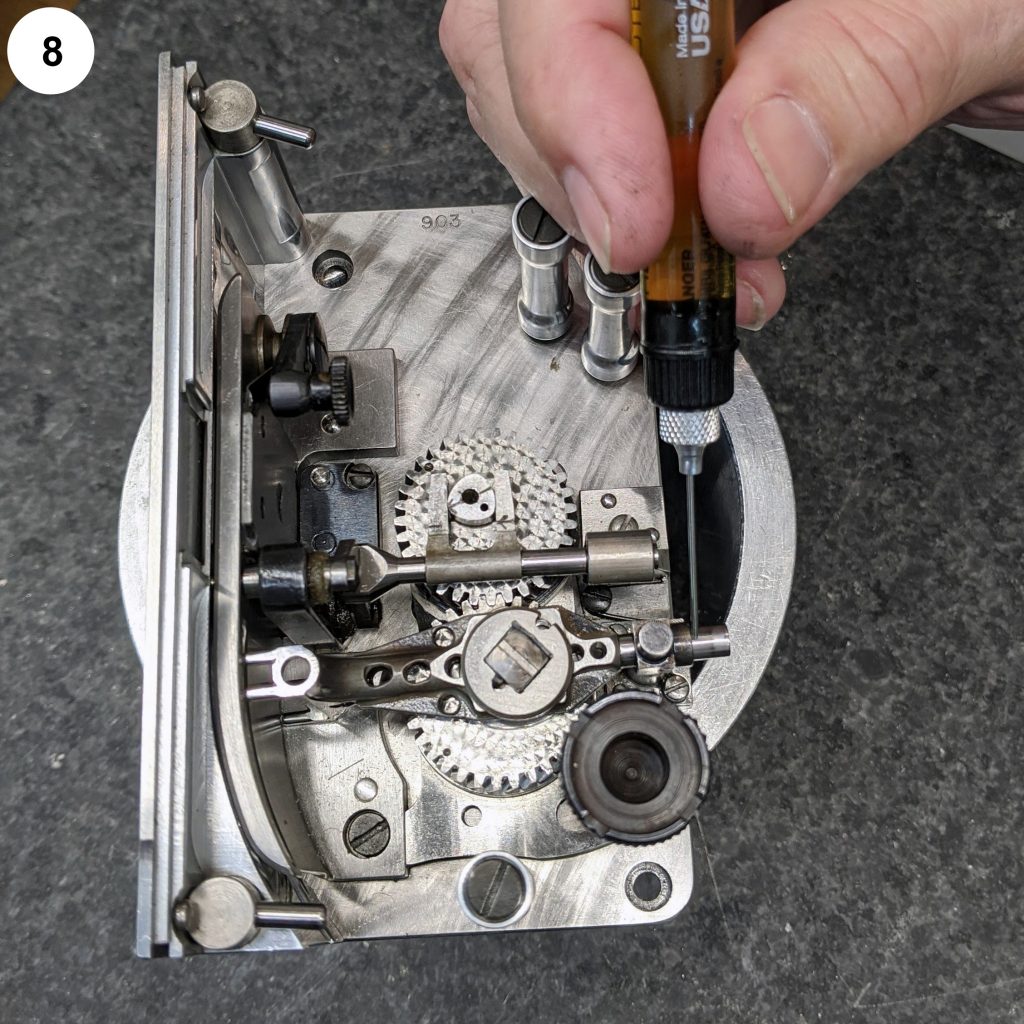

7. & 8. One drop of oil is needed on both the left and right sides of the pull-down claw pivot point.

9. The last oil point is hidden and many people forget it, but it is important that you oil this pivot point on the pull-down claw mechanism.

This procedure should be followed every 1000′, being careful to wipe off any excess oil.