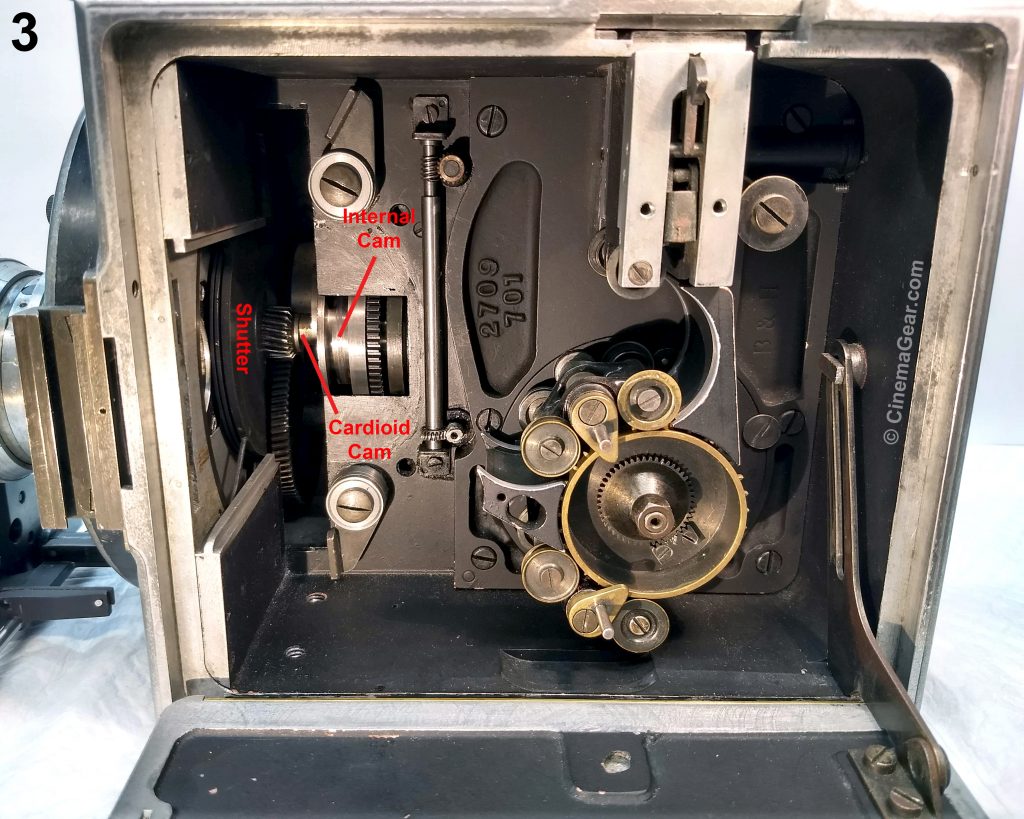

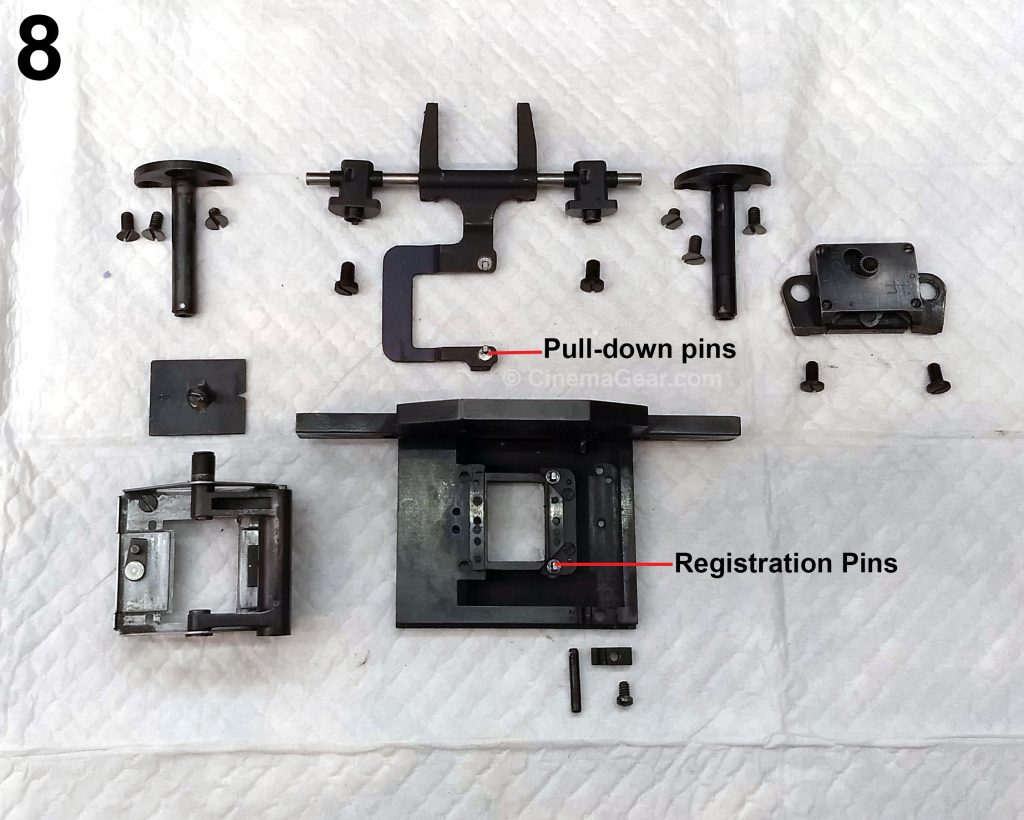

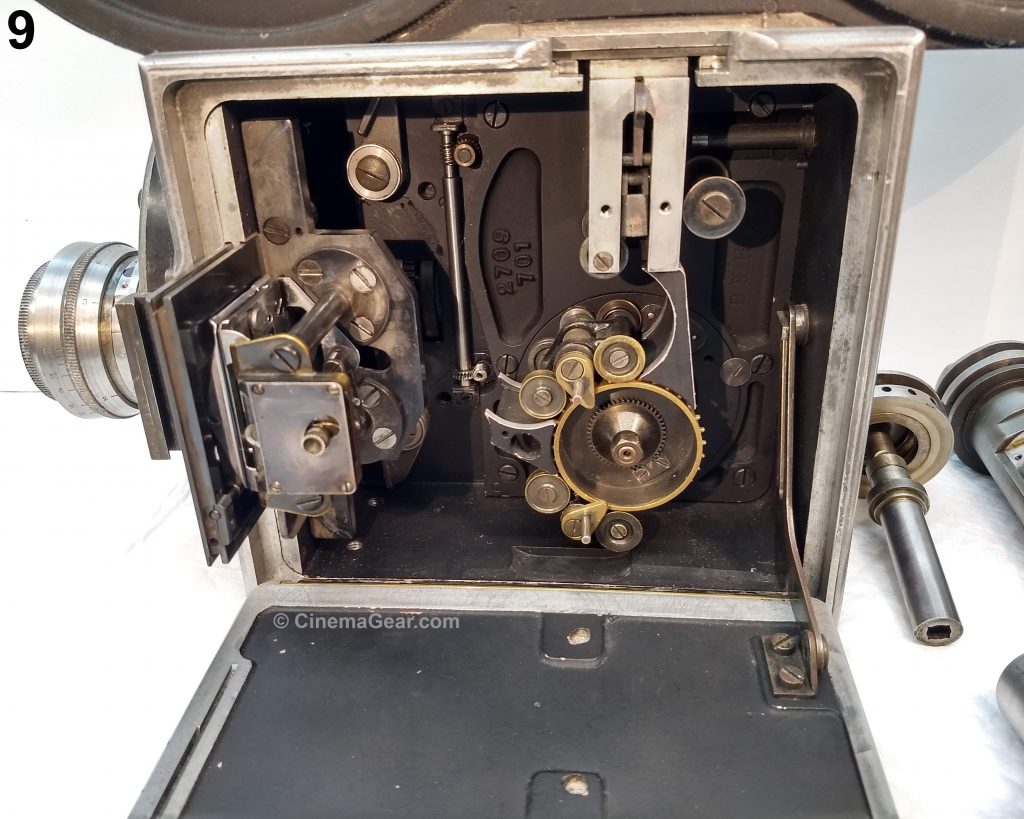

This week I was servicing a Unit “I” Shuttle movement from a Bell & Howell 2709. It occurred to that most people have never seen the inner workings that make this wonderful camera so steady. I thought I would break down the parts that make up the drive and the Unit “I” Shuttle. The engineering behind the Unit “I” Shuttle is an ingenious cam that actually has 2 working surfaces. One surface is a heart-shaped (or cardioid) cam that acts to move the pull-down claw through its cycle. The other is an internal cam that is more like a track that a roller bearing rides in to move the film on and off of the registration pins. The film rides between two very precision machined and polished leaves that actually keeps the film centered to the optical axis and guides the film on and off the registration pins.

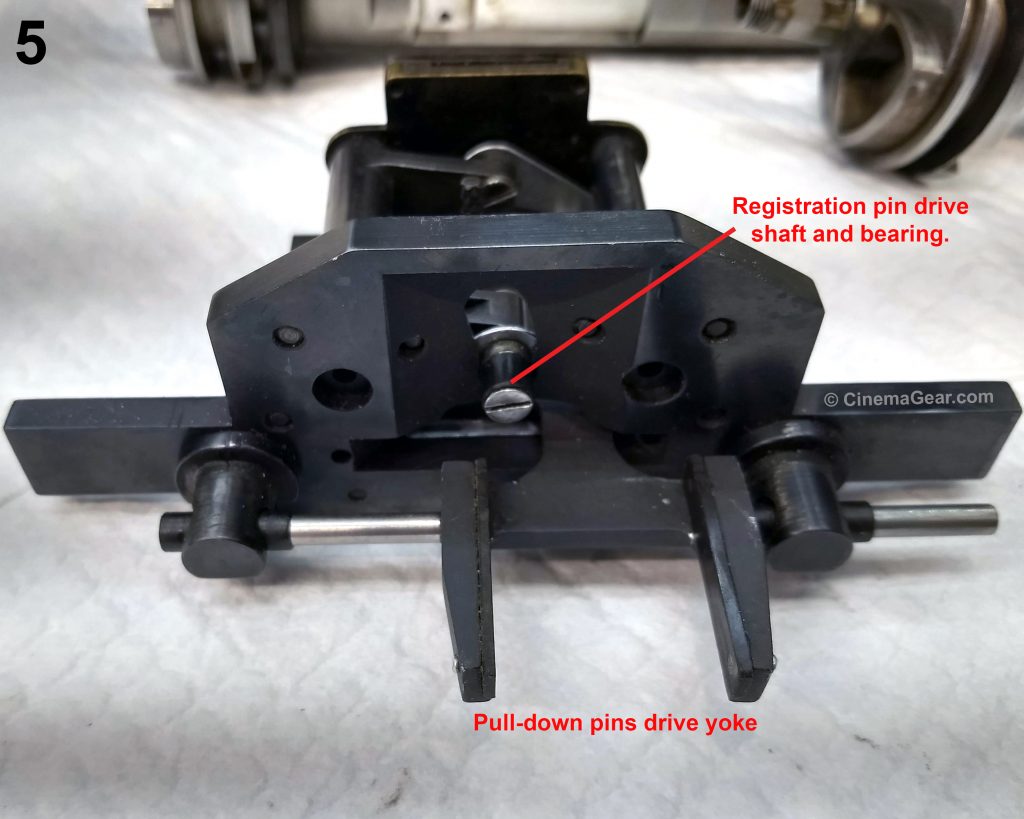

Image 4 shows the shutter shaft and dissolve assembly, and the profile of the cams. Image 5 shows where the roller bearing that operates the registration pin assembly and the fork that operates the pull-down assembly are on the movement itself. Images 6 and 7 demonstrate how the cam engages with these two parts of the movement. Image 8 shows all the parts of the movement itself. The design that incorporates the two cams on one shaft is part of what makes this camera so steady.