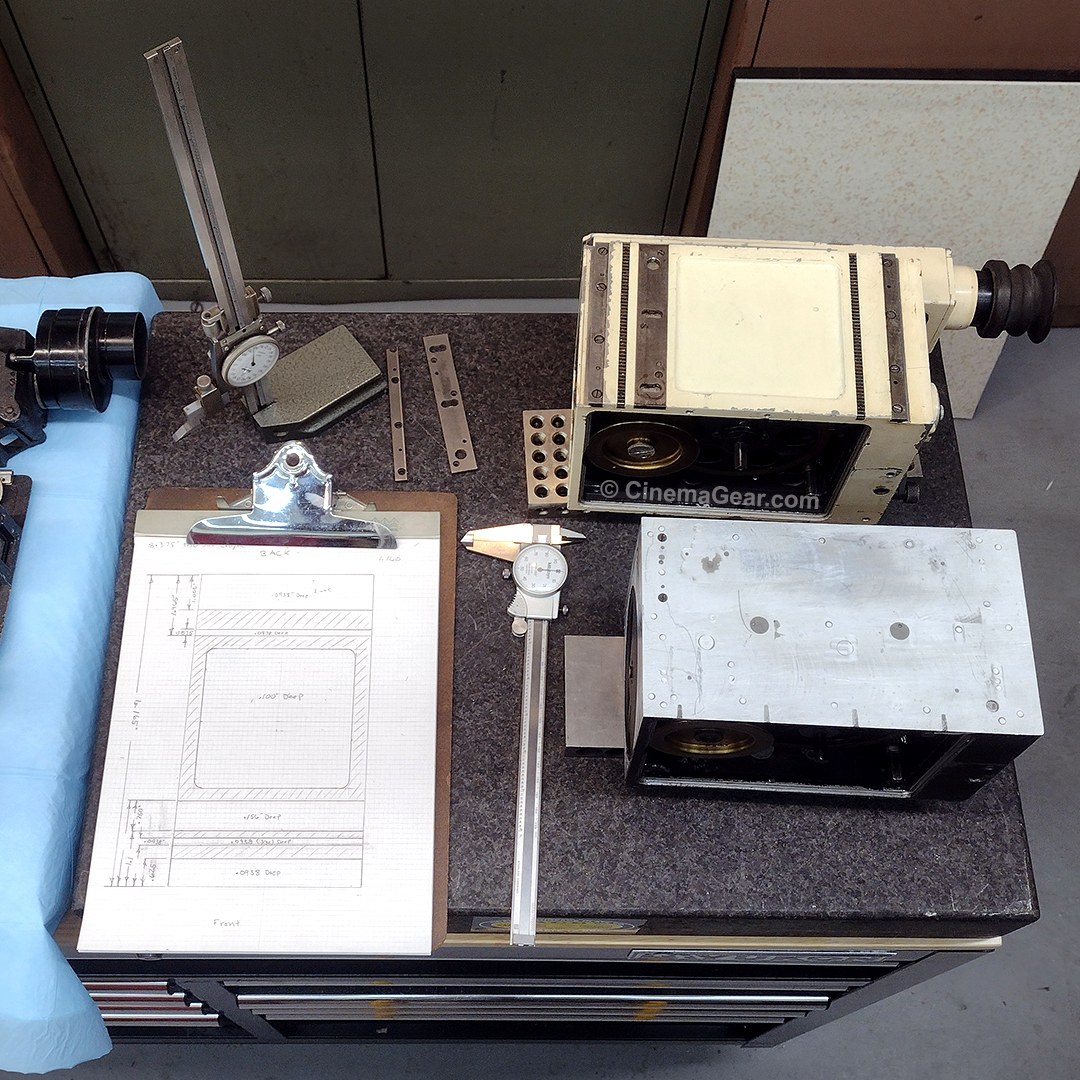

The starting point to restore Mitchell Standard #46 is to determine exactly what and how much material was removed from the original casting. The problem with this particular camera is that the previous owner machined away all of the material that registered the dovetails, the rackover registration plate, and the rack gears that slid the camera back and forth on the L-base. They also removed some of the material from the face of the camera that acted as a light trap between the L-base and the camera’s shutter. The first order of business was to measure exactly how much material needs to be added back to the camera casting. Using a known stock Mitchell Standard/GC camera body, I made a map of where all of the components belong. I then measured the positions for the dovetails, the rackover registration plate, and the rack gears so they can be put back into their original factory positions.

As you can see in the pictures, I have established a known reference point on the surface plate using 1-2-3 blocks to support the camera at the dovetails, and then measured from the 1-2-3 blocks to the bottom edge of the movement’s aperture on the stock camera. This allowed me to establish the correct dimension from the dovetail on the bottom of the camera to the camera aperture. The next step was to repeat this process on Mitchell 46 to get an accurate reading on how much material was removed from the bottom of the camera. I roughly laid out an aluminum plate showing approximately where all the components need to go. The thought is to solvent weld this plate to the bottom of Mitchell 46, pin and screw where possible, and then remachine the mounting positions for the rackover components. More to come!