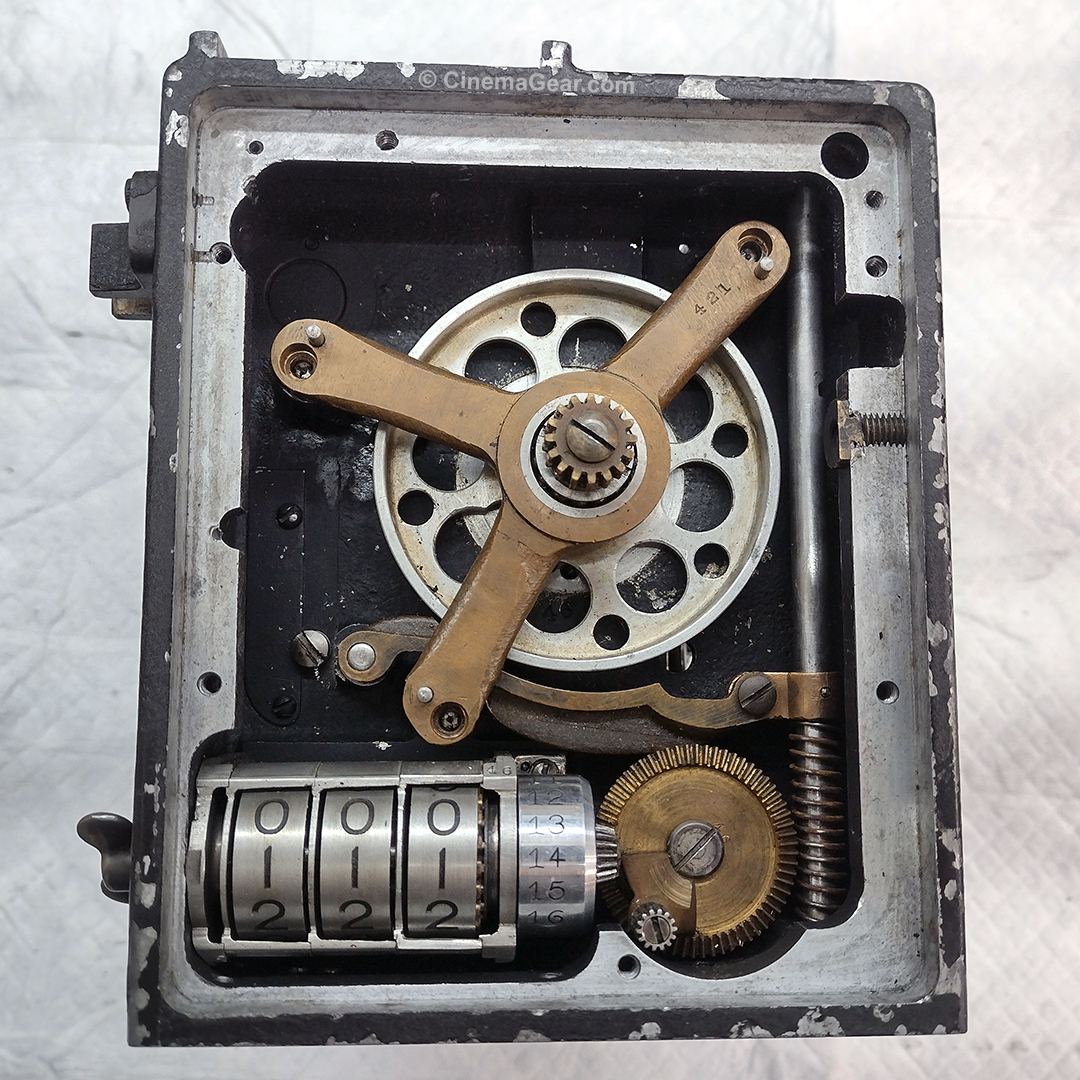

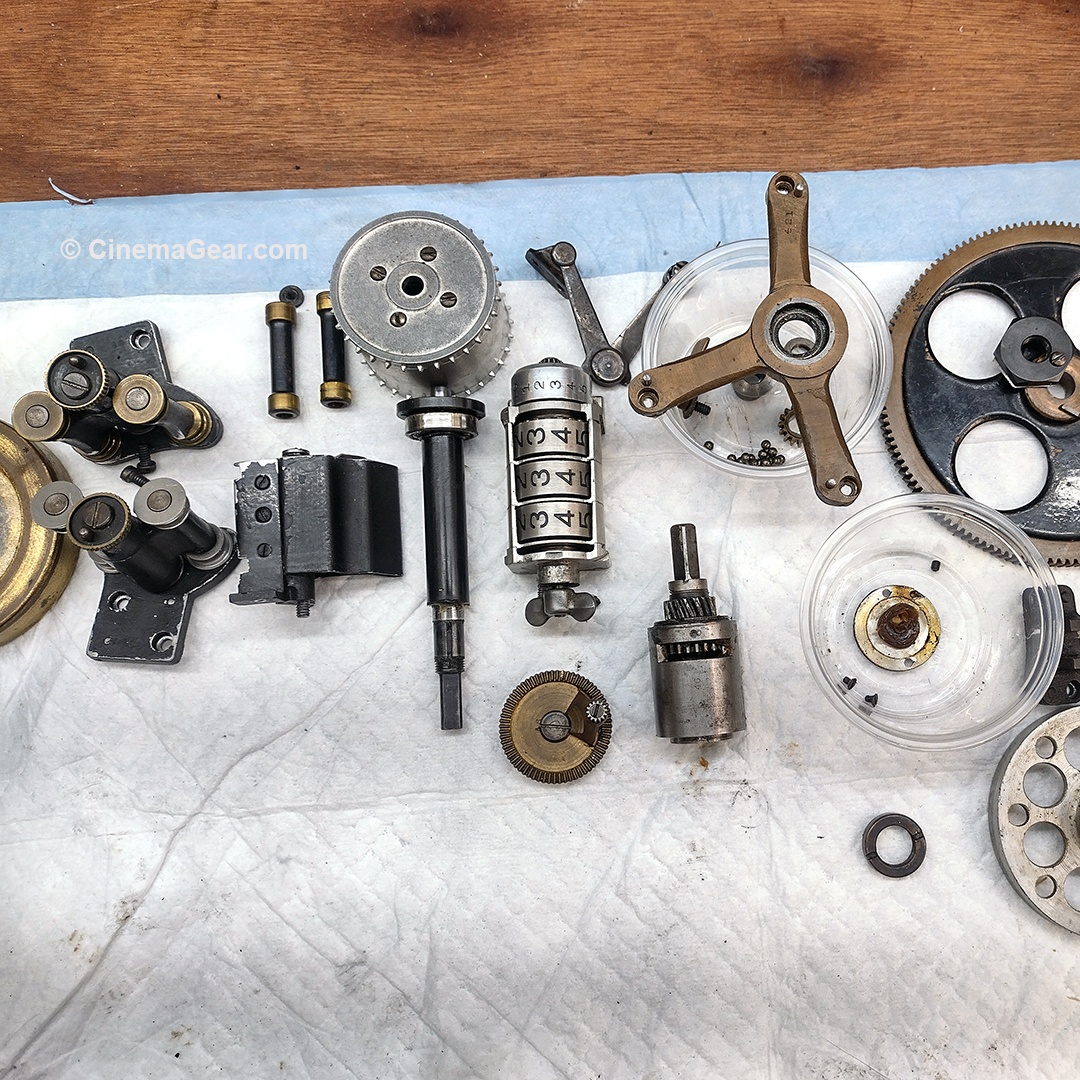

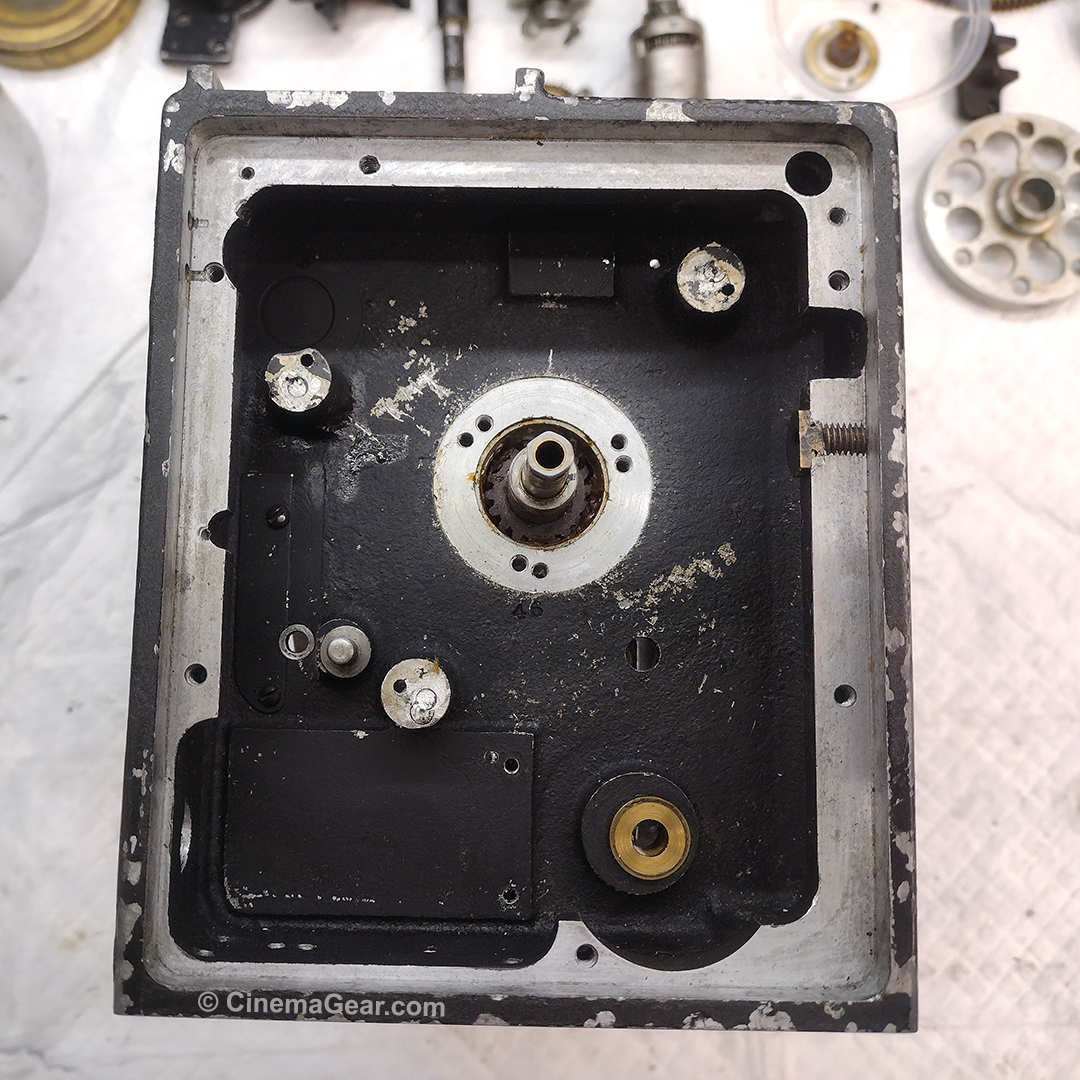

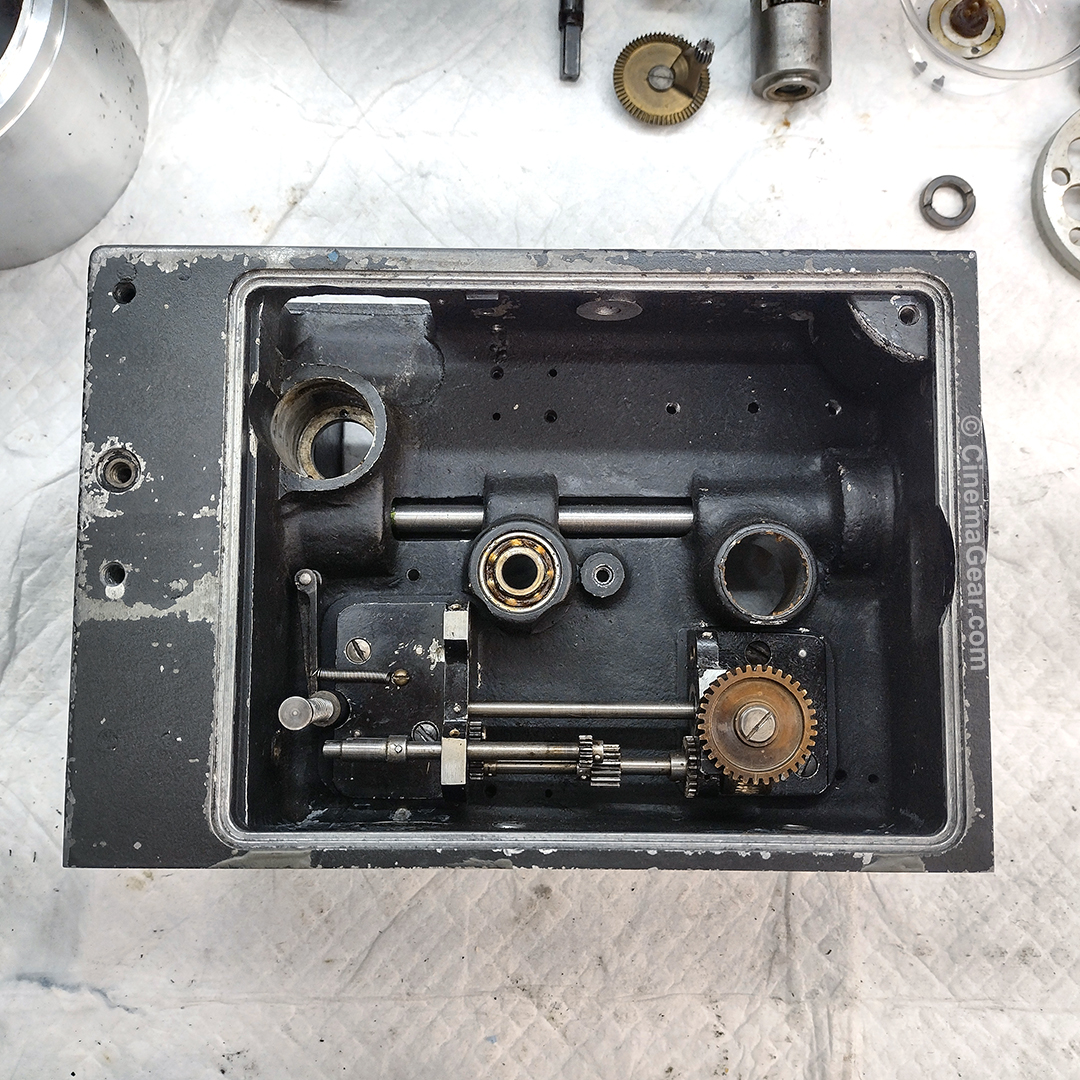

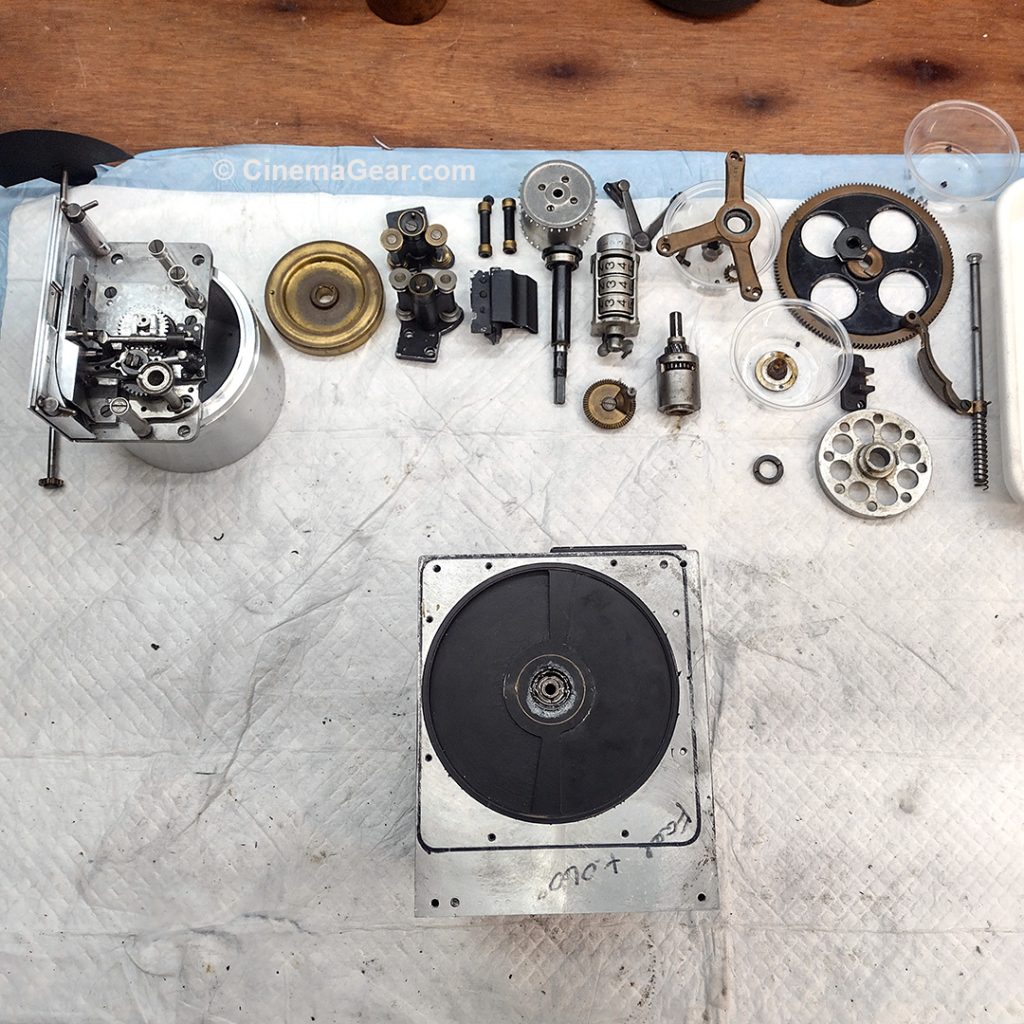

Progress at last! Sadly Mitchell 46 has been far more butchered than I had anticipated. Still, we shall persevere. I managed to get about 90% of the working pieces out of the camera casting, though the shutter shaft stubbornly remains in place due to corrosion. The screw that holds the focal plane shutter to the shutter shaft is tenaciously holding on and I have been working with penetrating oil and heat to try to gently remove it. Once the shutter shaft is removed, all of the working parts will finally be out of the camera casting. The casting can then be thoroughly cleaned and degreased, and new aluminum plates can be bonded to the casting to prepare to restore it to factory dimensions. I will have to make a series of fixtures so the casting can be mounted on the milling machine, allowing me to indicate the casting true to the shutter shaft bore, and then the places for the dovetails, rackover stop blocks, and rack gear can be machined into the new material. In the process of taking everything apart, I discovered that the dowel pin and screw holes that hold the rear shutter shaft bearing support in place have sheared off screws and dowel pins left in them. All of that will have to be undone. Even though the variable shutter breaking assembly was left in place, most of the gearing that operates the variable shutter mechanism has been removed and probably lost forever. I think I have most of the parts to put that back to its original configuration, we will have to see as the restoration progresses.