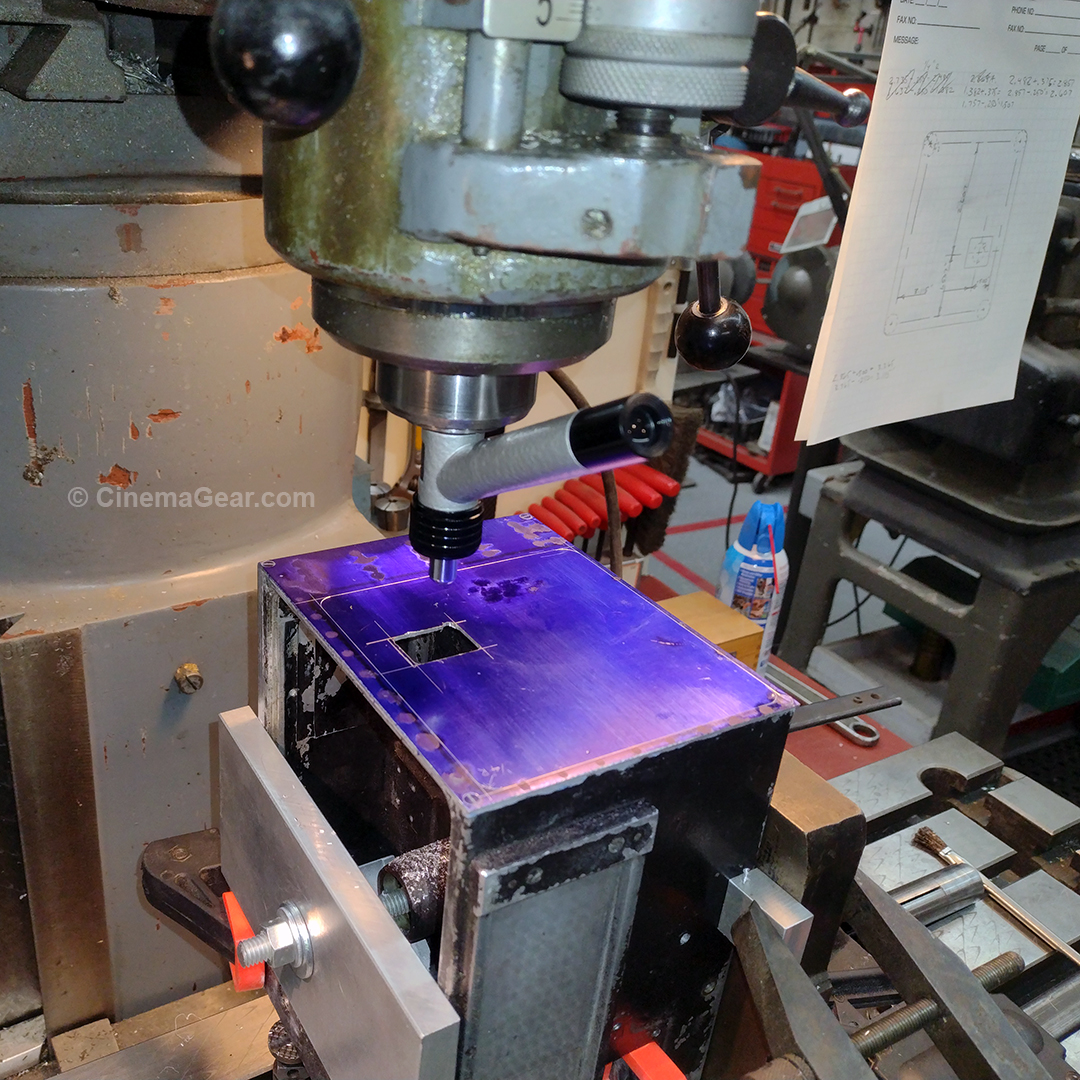

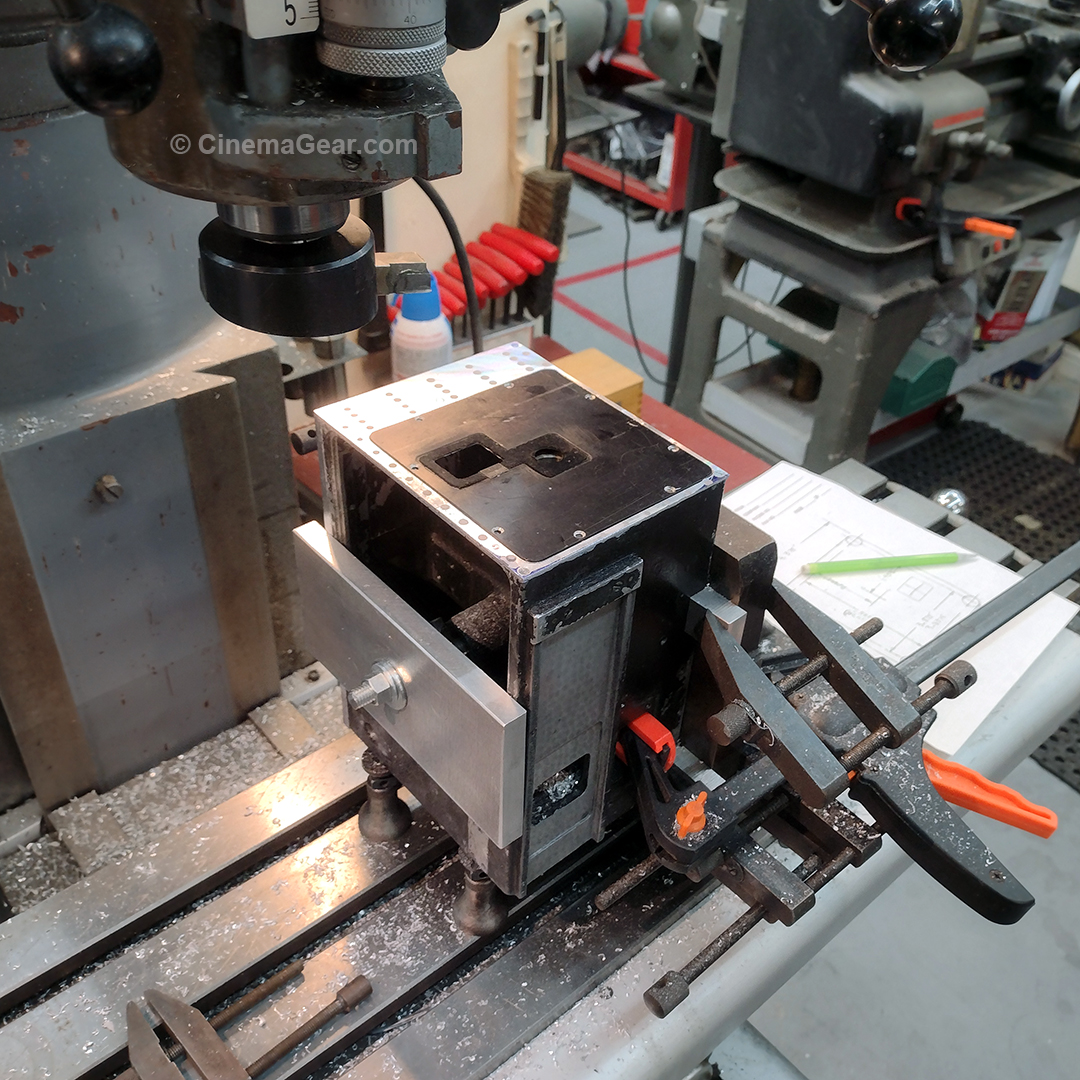

With my work on the Dykstraflex camera complete, I have returned my attention to Mitchell 46. I dusted off the setup on the mill, re-indicated all the surfaces that needed to be true, and began to make a tool path map. I had transferred the actual position of the camera movement to the aluminum plate I bonded to the front of the camera. Using a precision borescope, I mapped where the actual aperture would be in space, calculated all the offsets from those positions, and programmed those into the DRO. My calculations compensated for a ½ inch diameter end mill.

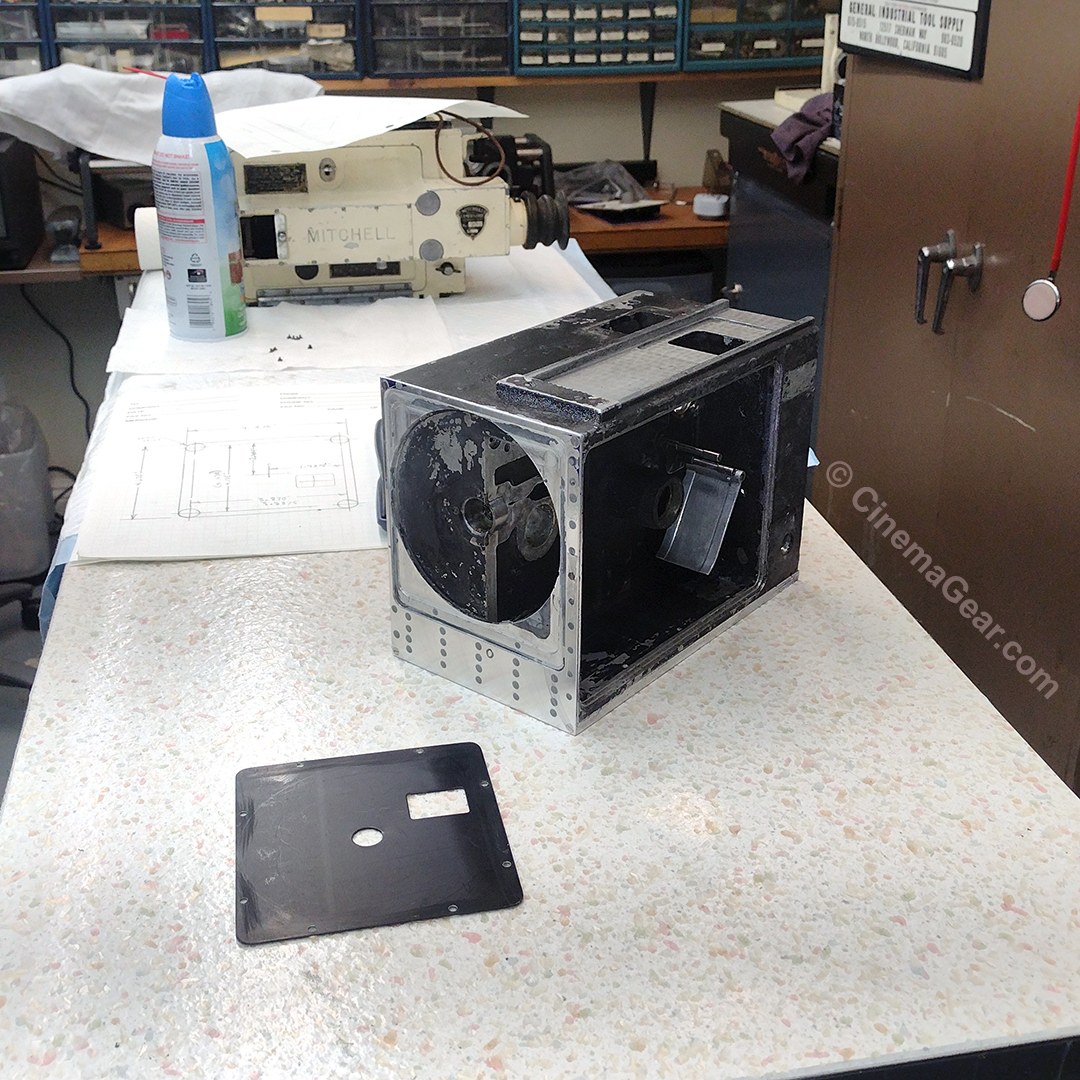

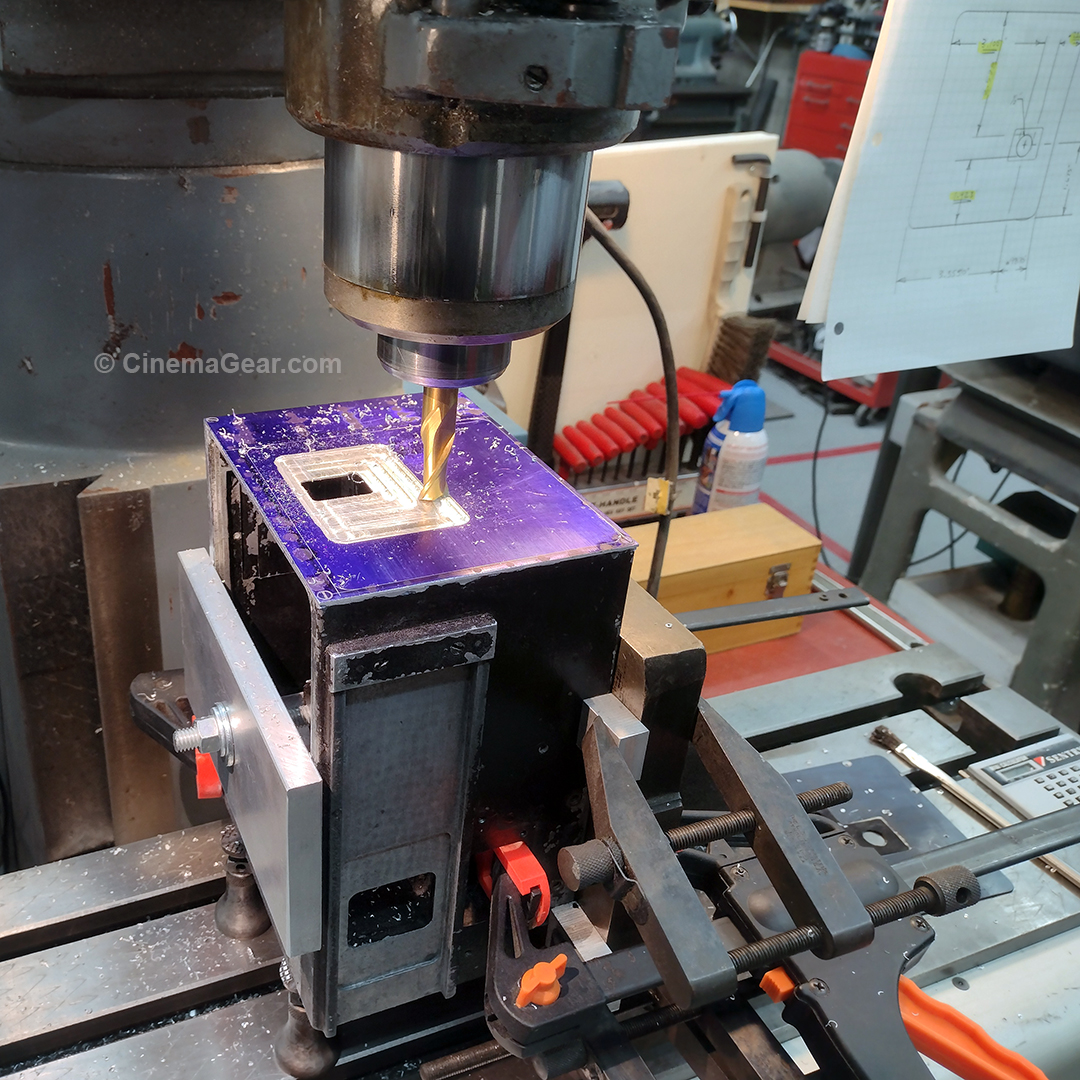

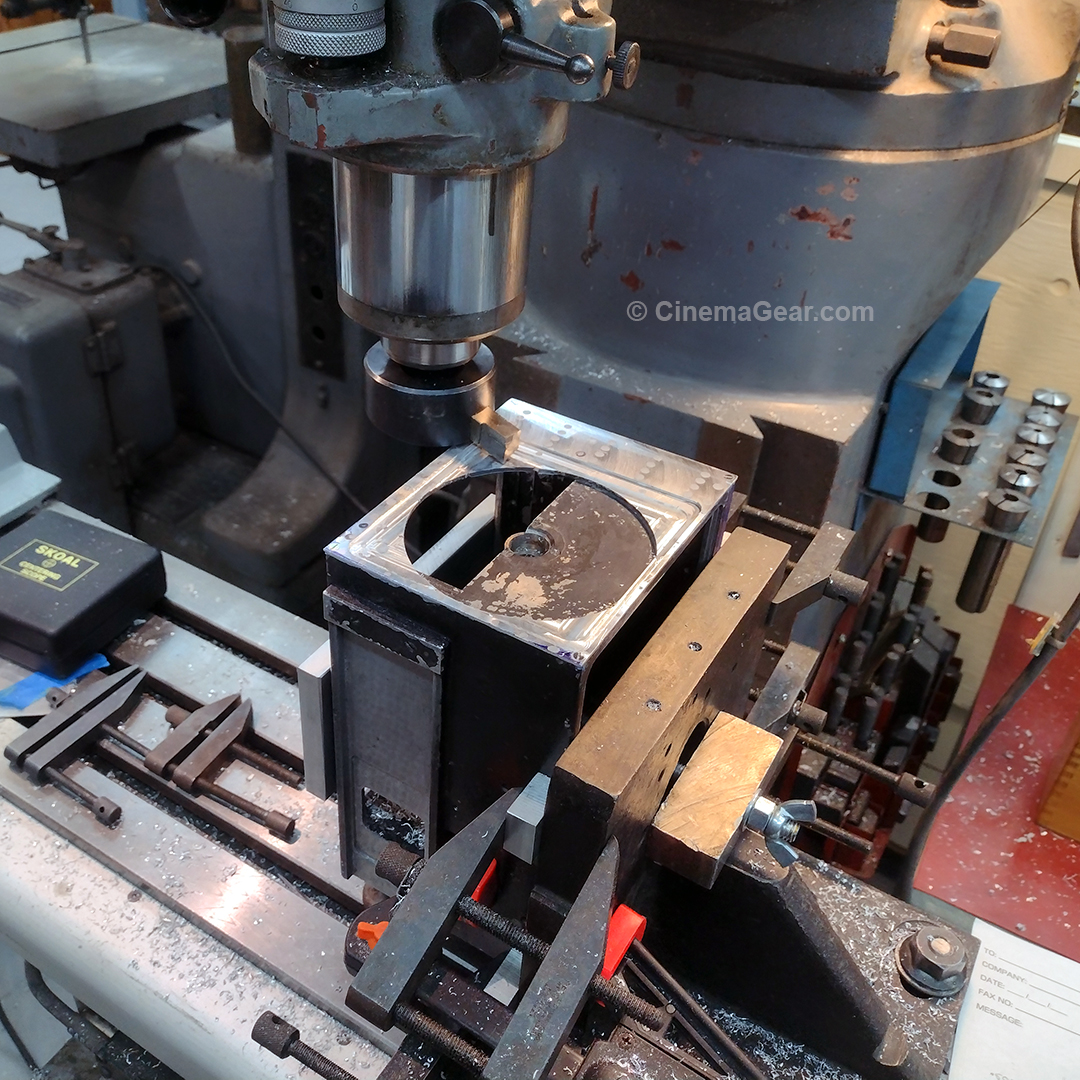

I then began removing the unnecessary material from the replacement front plate. The purpose of this entire operation was to leave a pocket in the front of the camera that the shutter light trap cover plate would fit down into, and to return the camera to its proper factory dimensions from front to back. Once the pocket was machined, I changed out the tooling to a fly cutter so that I could machine the front of the camera to the correct dimensions, and make it flat and parallel to the movement. Working in .002 of an inch increments, I went over and over the face of the camera with a fly cutter until I reached the correct dimension and flatness. The JB Weld, and the myriad of countersunk holes it protruded through, worked very well.

Then it was back to the ½ inch end mill to cut the pocket to the correct depth so the light trap cover plate would sit flush to the newly machined face of the camera. Step one completed on Mitchell 46! Next phase is to lay out and machine the plate I bonded to the bottom of the camera.