An interesting question was posed recently to the committee I serve on at the Academy of Motion Picture Art and Sciences asking about the history of geared pan/tilt heads. The questioner was only aware of the Worrall geared head, so many of us contributed our experiences with other styles and manufacturers of geared heads that preceded and were contemporary to the Worrall. This got me thinking about 8 or 9 boxes of parts that I had been hoarding for the past 10 or 12 years that had, what I hoped were, enough parts to make 5 what I always called Mitchell Straight Heads. I’ve never been quite sure if that is the proper name, but that is what I know them as. Regardless, these are amazing small form factor geared heads that I have used to do motion control, locked off plates, second unit pans and tilts, and many other shots over the years. Basically designed to go under the Mitchell Standard or NC, I have been scouring my library of Mitchell sales brochures and service manuals trying to find when this product was introduced. My catalog of the right vintage is lost in the chaos at the moment, so I will have to get back to you on that. In the meantime, here is the resurrection of 4 out of the 5 Mitchell Geared (Straight) Heads in my collection.

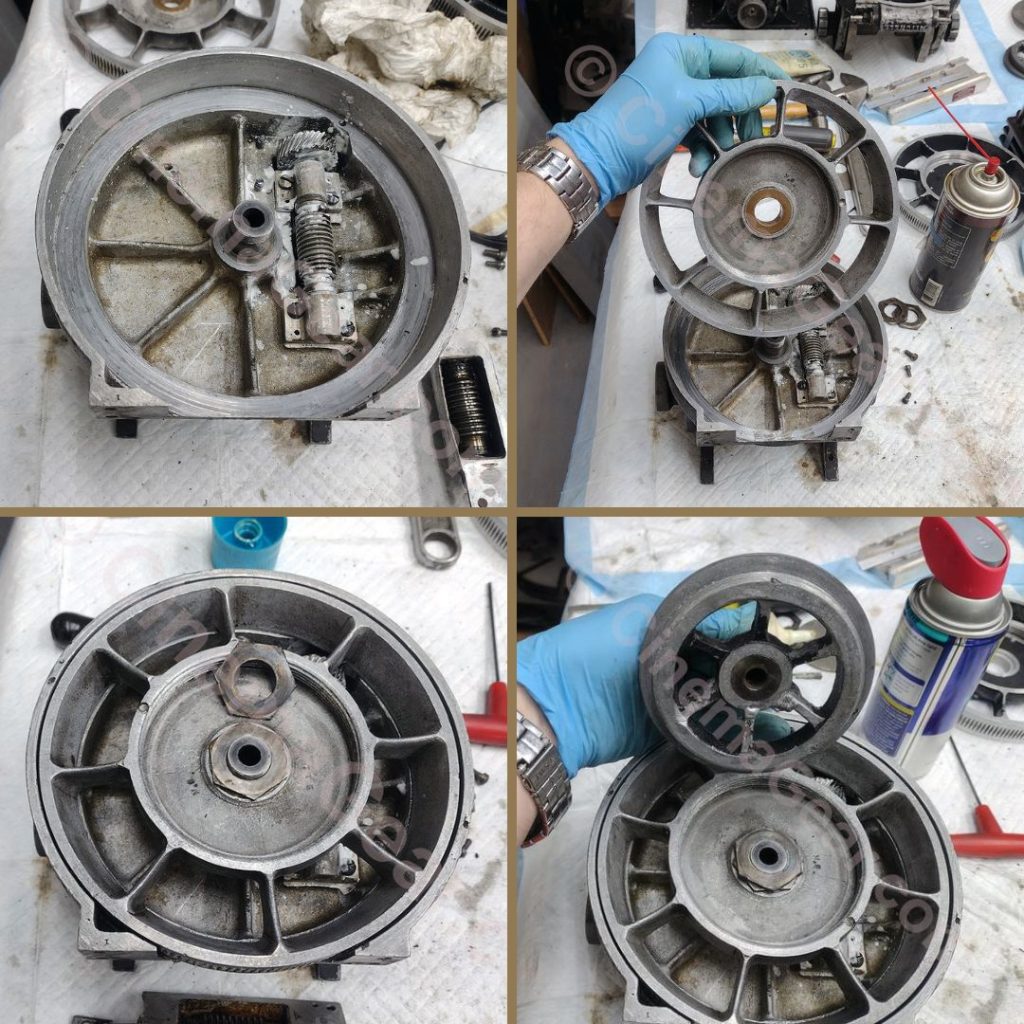

It began with the great sorting of parts late one Monday afternoon. I separated the units with broken castings, bent shafts, and other mangled parts from those that were mostly intact. There were two that were less broken than the others, so that is where I started. I gathered the necessary parts, cleaned and degreased them, and then was able to assemble the first two geared heads.

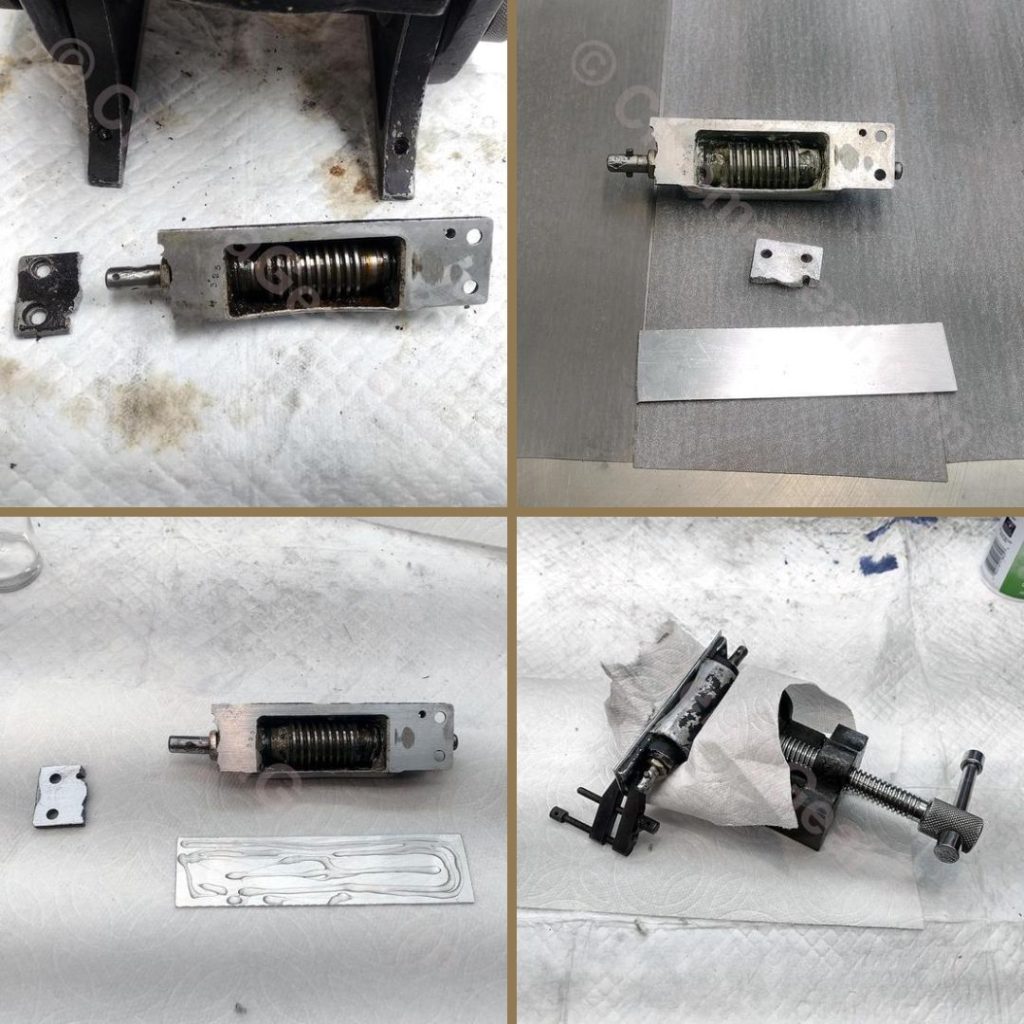

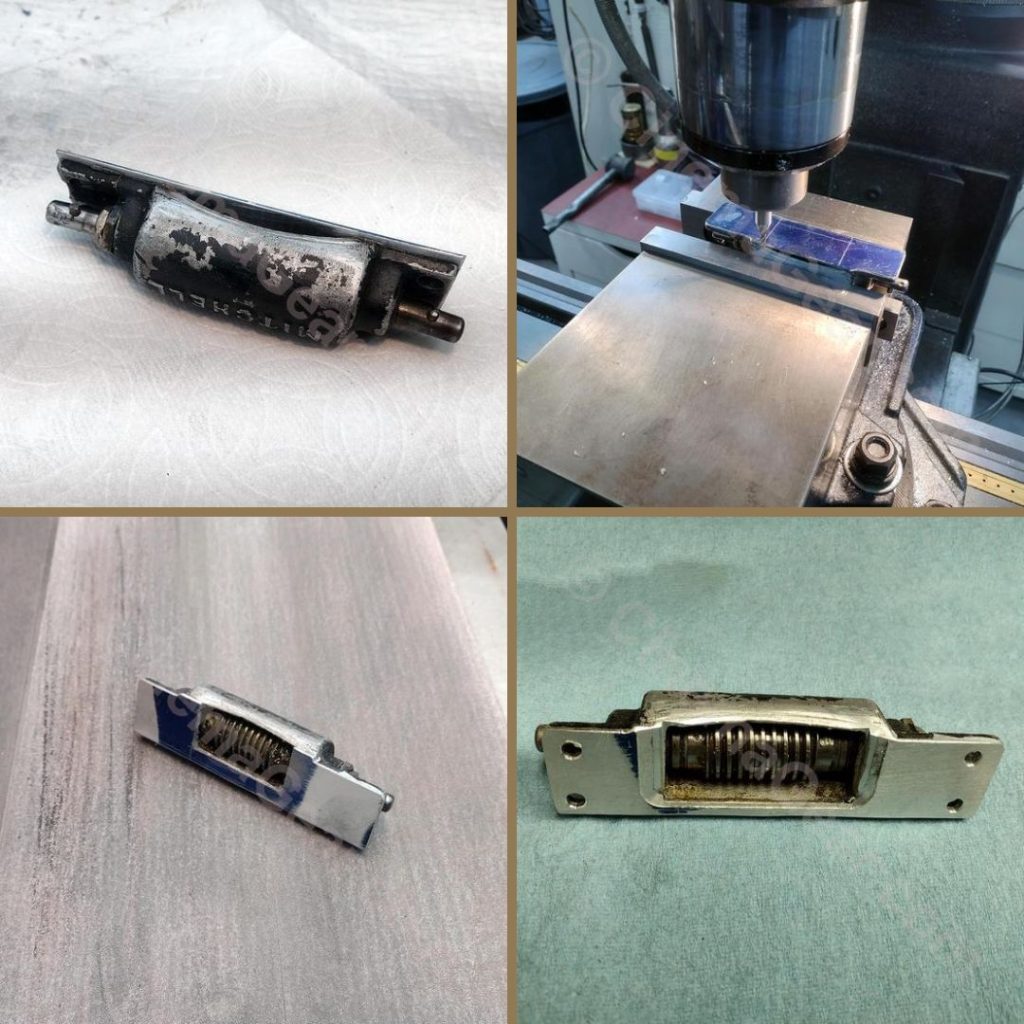

Out of the remaining 3 geared heads, there were only enough parts to restore two complete units. Even those two required me to pull some parts out of other parts bins. The next task was to straighten severely bent shafts, repair broken castings, clean mangled gear teeth, and finally reassemble the other two geared heads. It was interesting to see that the pan worm gear assembly was broken pretty much in the same way on both geared heads. My guess is they had the pan crank on the pan drive shaft and they knocked over or dropped the geared head. When the head hit the ground, it looks like it hit on the pan crank and split the casting and tore it off the geared head. Fortunately the broken pieces of the casting were still there. I sanded down the existing pieces of the casting so that I was able to create an aluminum shim and epoxy it to the back of the castings. I scavenged bearings for the pan worm gear assembly as well as springs, clutch plates, and a tilt arbor upright, and was able to use these parts to reassemble the two other geared heads. I will spare you the gorey details of all the intricate little bits and pieces that make up the drive components for pan and tilt, and let’s just say I was able to make four working Mitchell geared heads in the end from the boxes of parts for five.

In the end I still have some parts and a partial casting for a fifth geared head, but not enough to complete it. Interestingly, I found among the Mitchell Geared Head parts a dovetail assembly made by Camera Equipment Company (and apparently in the F&BCECO inventory) that allowed you to mount a Bell & Howell 2709 to a Mitchell Geared Head and be able to rack the 2709 between shooting and critical focus positions. Now that the four geared heads are in working order once more, I am trying to decide whether or not to do a deeper cleaning and repaint them. Comments welcomed.

I leave you with this final question: Do you know what Mitchell called these geared heads when they were originally introduced? I am guessing that they were introduced in the late 1920s or early 1930s, but I am not sure. Do you have a sales brochure or a service manual that shows them? I have several copies of the manuals and parts breakdowns for the Mitchell Friction Head which looks very similar to this geared head, but it is not the same. As always, your input is greatly appreciated.

Thanks very nice blog! holidays on gozo