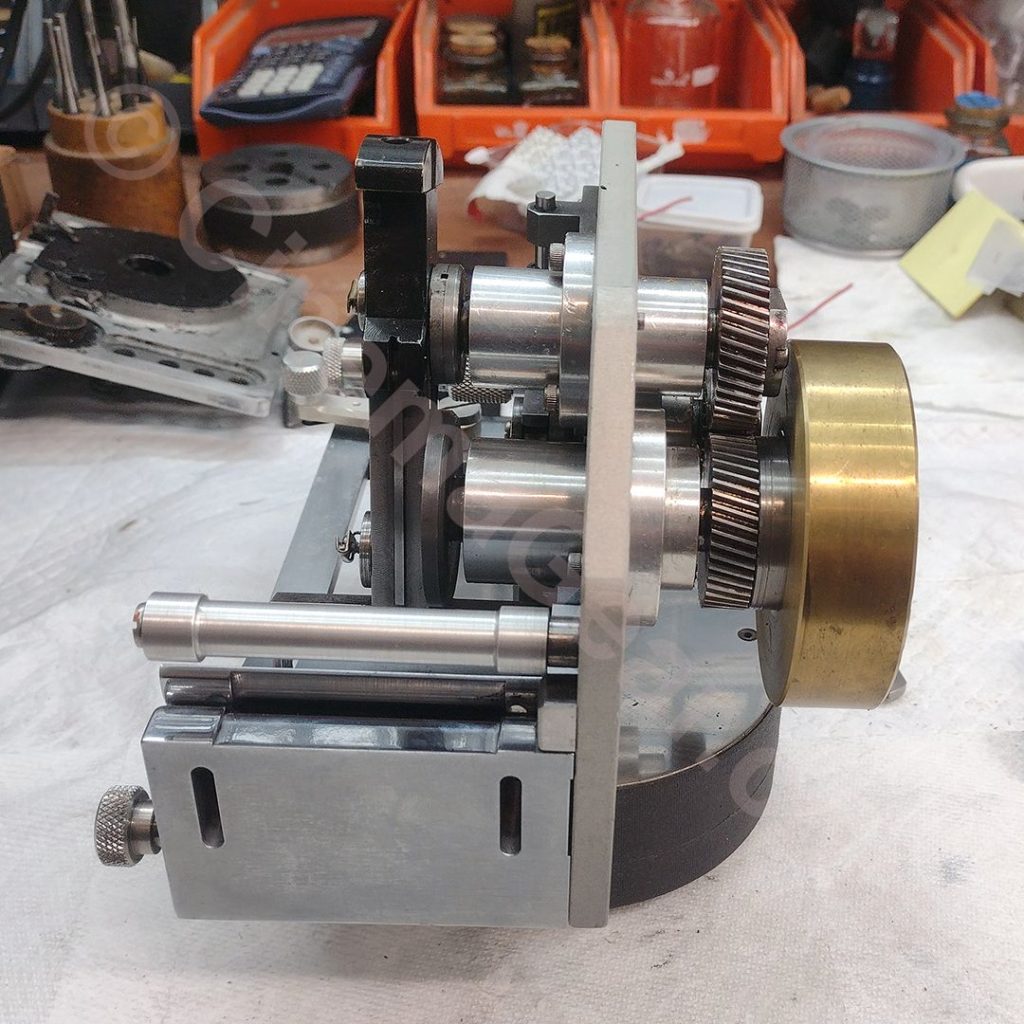

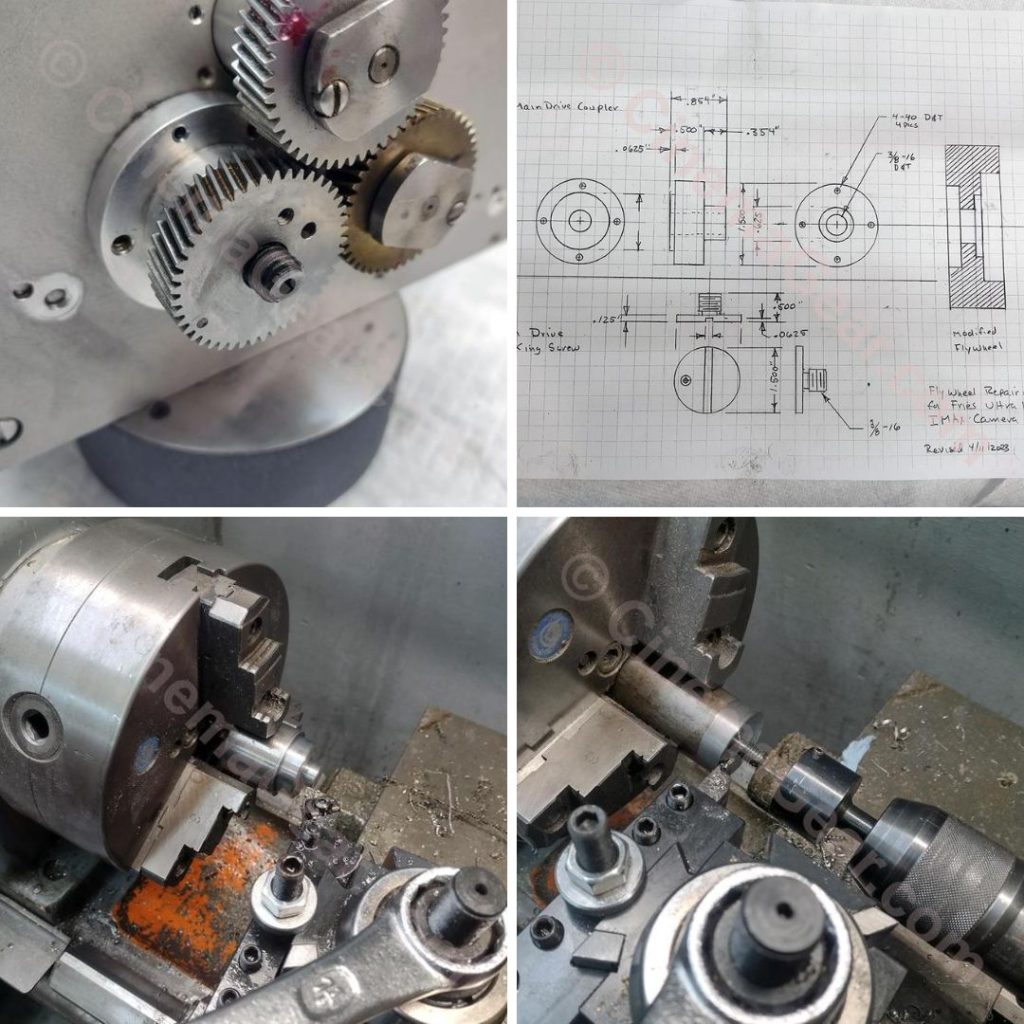

This week I continued work on the Fries Ultra 70 IMAX format camera. It was mainly a week of head scratching, doodles, starting over, and eventually creating successful parts. As I mentioned last week, my plan is to machine a new flywheel hub that will attach to the movement using the remaining threads on the drive shaft. The first thing I did was grind off the sheared off fragments that remained on the drive shaft to make a clean surface. Next I sat with calipers, micrometers, and thread gauges to figure out the features of this new hub. The hub has to do six things:

- It has to thread on to the remaining threads of the drive shaft.

- It has to hold the main movement timing gear on its bearings.

- It has to create a new mounting axle for the flywheel.

- It has to provide a threaded socket for the flywheel retaining screw.

- It has to hold the entire flywheel assembly at the proper distance from the other movement timing gears

- It has to reposition the flywheel so it mates with the shutter drive coupler.

I made a couple of false starts and wound up with parts that didn’t space everything out correctly, before honing in on the proper dimensions to make everything work together. This process required machining the flywheel to remove the damaged areas, creating two pockets in the flywheel for the hub assembly to work in, machining the new hub, and machining the flywheel retaining screw. Next week, if I survive, I have to reestablish the timing between the flywheel, the movement, and the shutter. This will probably involve a combination of keyways and locking screws, but I will have to decide on that when my mind is clearer. The pictures included show the sequence I went through to complete these parts. More to come next week.