Last week someone asked if I could show the basic care and feeding of a Unit “I” Shuttle and where the major oil points are. I originally showed the Unit “I” Shuttle as I was preparing to install it in this Acme Model 6 camera, so I thought I would give an overview of my work to this point.

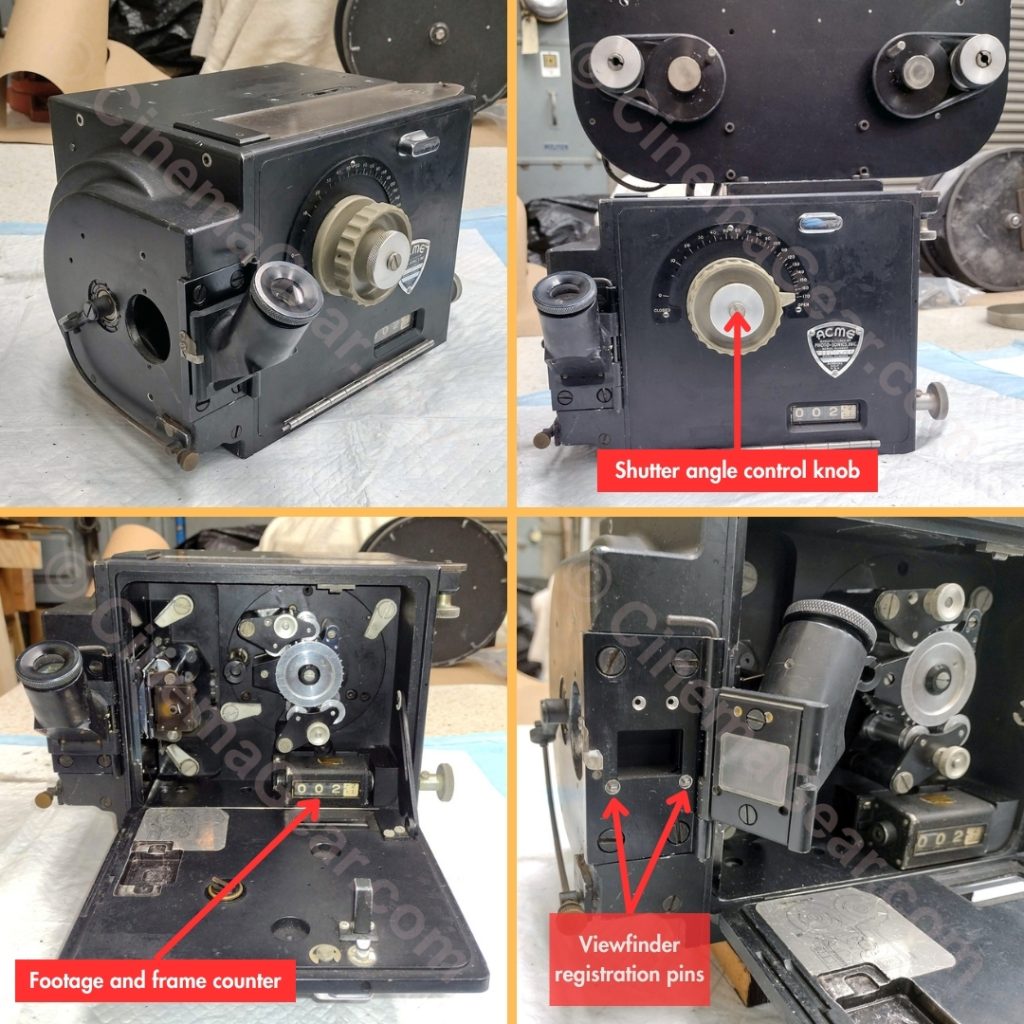

The Acme Model 6 is a successor to the Bell & Howell 2709 and incorporated into its design the most requested features of animators and optical printer camera operators. Among these improvements are a built-in through-the-lens viewfinding system that includes registration pins for precision line-up, an operator friendly fade/dissolve control, a built-in automatically reversible magazine take-up tree, and a family of easily interchangeable drive motors.

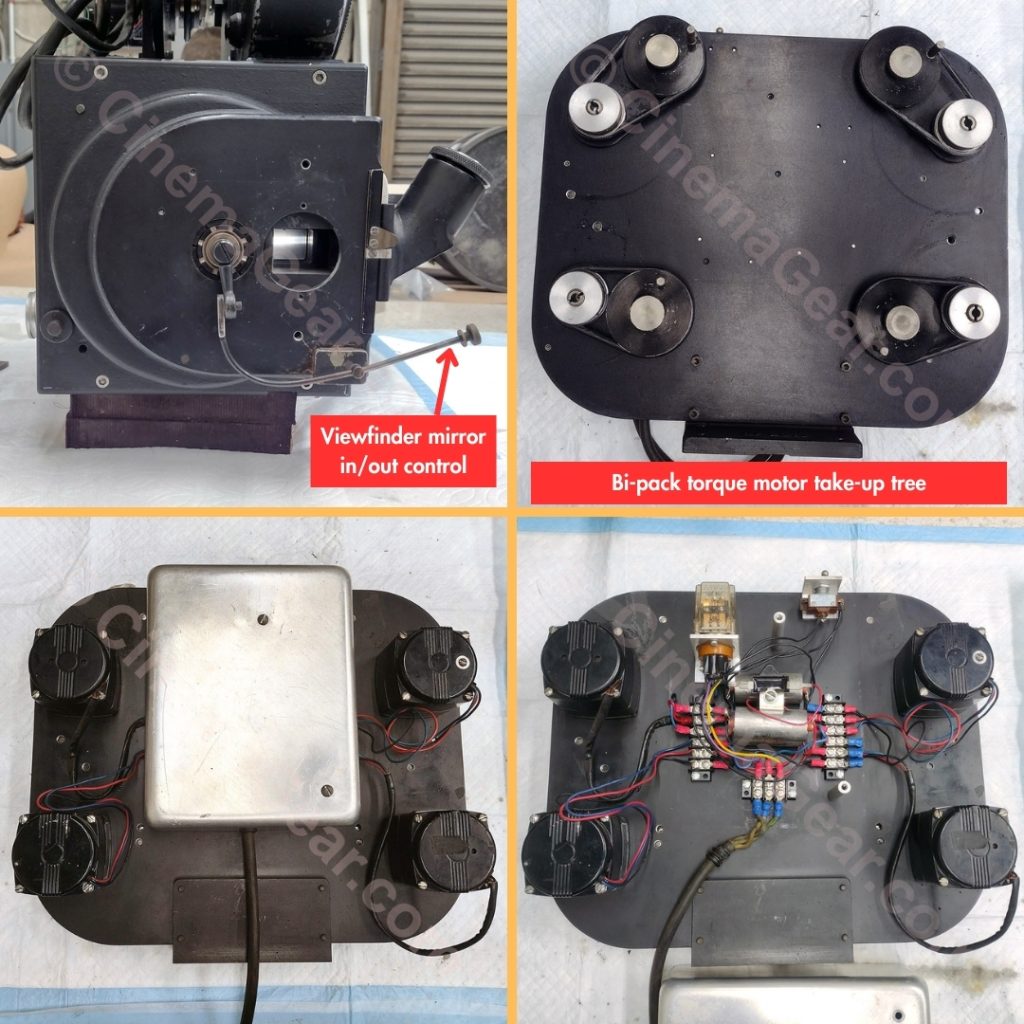

The camera I am working on here has been converted for bi-pack and has a torque motor driven bi-pack take-up tree in place of the original gear driven single magazine drive. I cleaned and lubricated all the moving parts of the camera and I thought I would share the proper way to lubricate the movement and the cams.

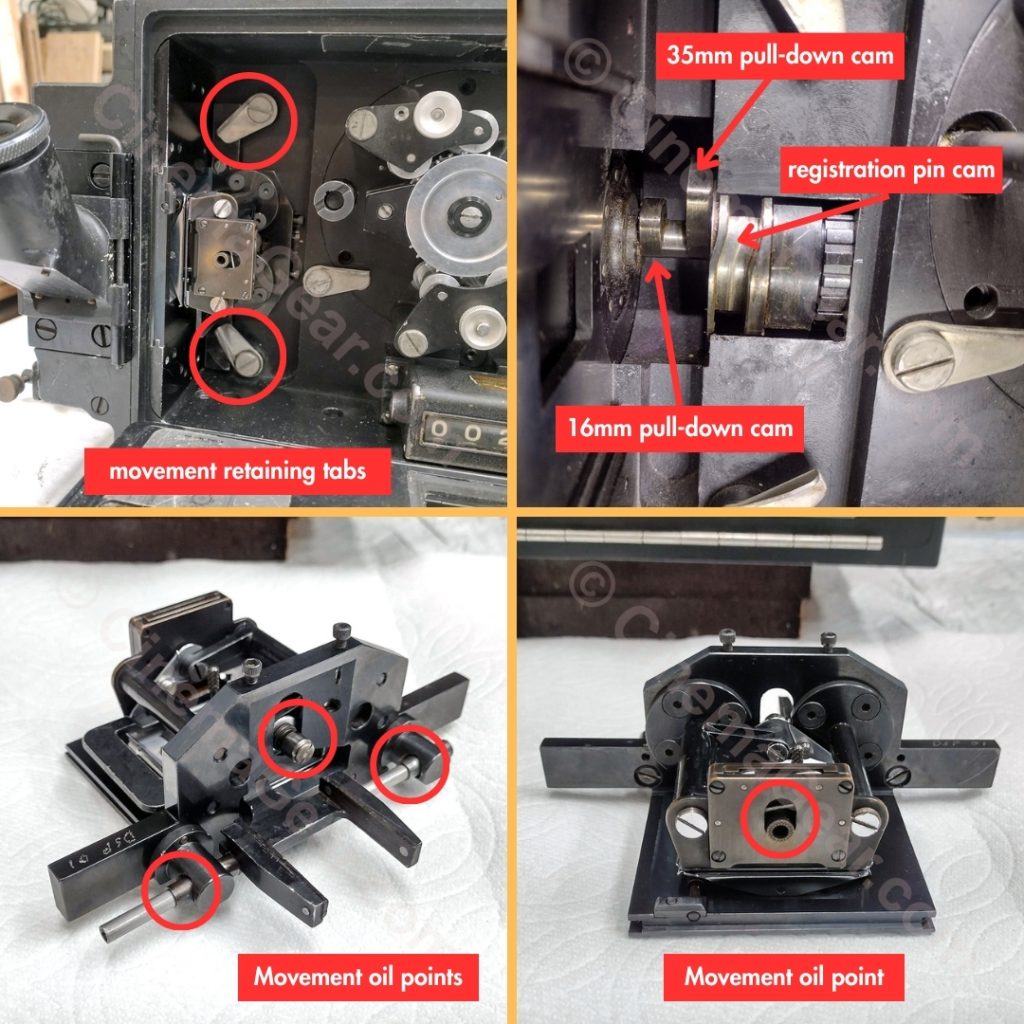

There are some places where grease is appropriate, and other places where grease should never be used. As the camera is run, it will inevitably make film chips and fine film dust from the action of the registration pins and the pull-down claws. Grease attracts this type of dirt, so grease should only be used on the pull-down claw cam and the registration pin cam because they are semi-protected when the movement is installed in the camera.

The movement, however, should never have grease on any of its moving parts. Beginning on the back of the movement, there are two bushings that support the pull-down claw guide rail. A small drop of oil should be placed on the guide rail at the front and back of each bushing, being careful not to over oil. There is a small flathead screw that holds a roller on the registration pin assembly. The roller engages with the slot-shaped cam inside the camera. This screw and roller should be removed and a small drop of oil put on the shaft that holds the roller in place, then both should be returned to their places, being careful not to over tighten the screw.

On the front side of the movement, there is a small button that disengages the pull-down claw from the film path. This should be pushed all the way to its top most position so the pull-down claw is retracted. Using a cotton swab soaked in oil, carefully wipe a thin coating of oil on the now-exposed moving part. Once done, this part should retract on its own, and then the movement is ready to reinstall in the camera. Another Acme Model 6 brought back to life!