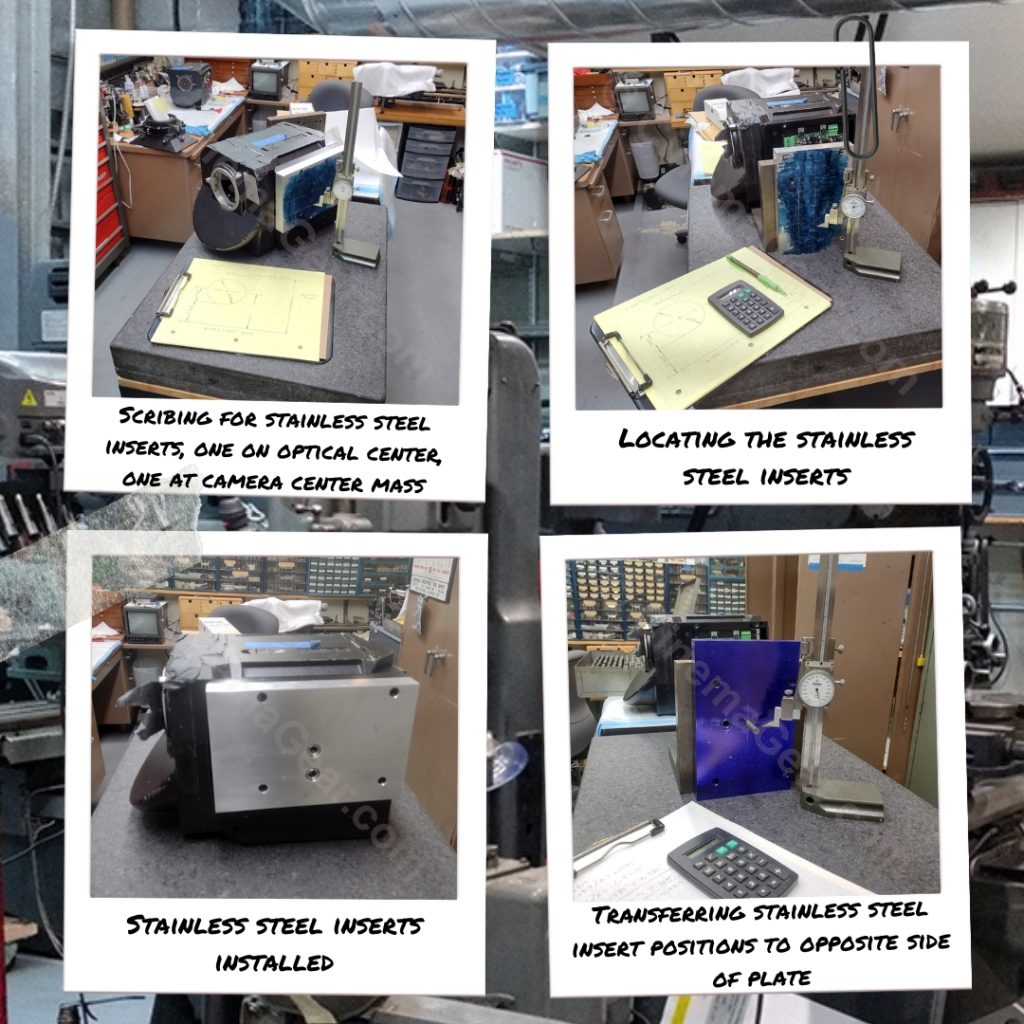

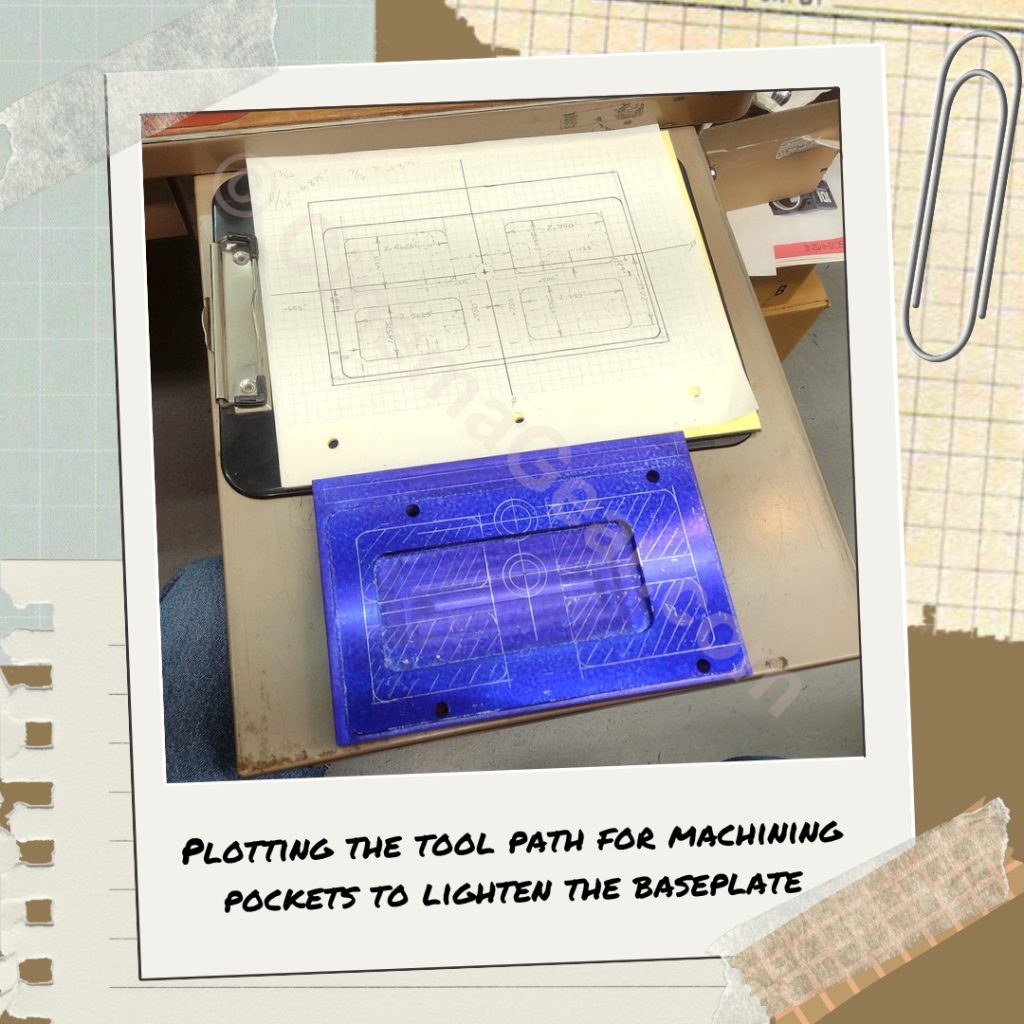

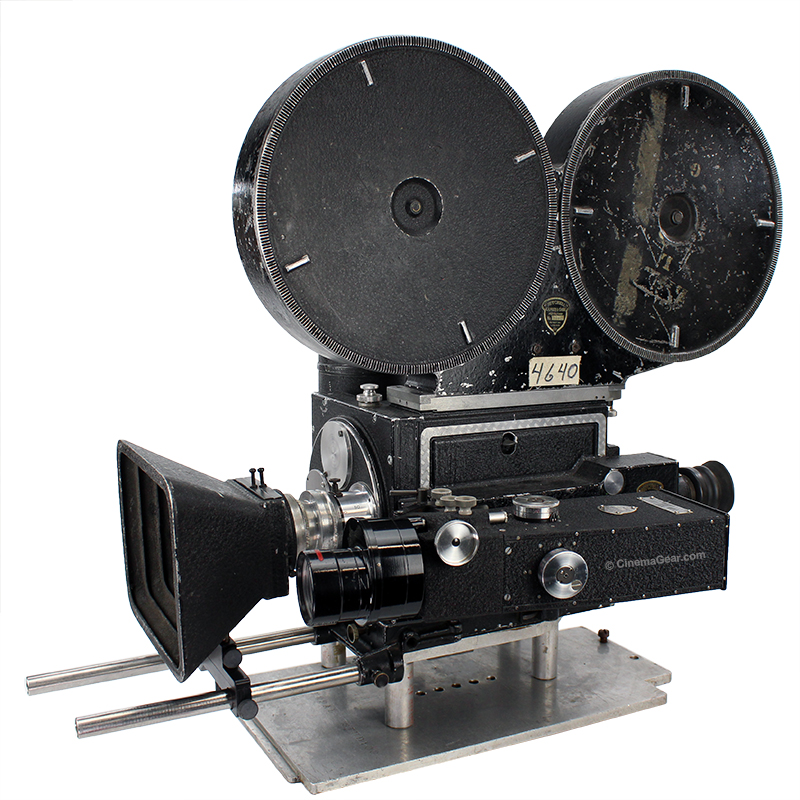

In the past, I have shown you the CP65 ShowScan cameras that I am helping to rebuild and make production ready. My friend Arnold Peterson is just about finished with redesigning the electronics, so my job is to get the cameras ready mechanically for him to test. After several meetings discussing what the look and feel of the cameras should be, I took on two projects. The first project is to make new, improved baseplates so the cameras can be tied down to modern pan tilt heads. The next project will be to service the movements and make sure they are ready for electronics testing. This week, I have been laying out and machining the baseplates. I designed the baseplates based on my experience as a visual effects cameraman. I found that it was very useful when the cameras were designed to have multiple tie down points, some on optical center, and some as close to the center of mass of the camera as possible. Working with that in mind, I machined the baseplate to have the same basic footprint as the camera itself. Originally, I was going to put multiple threaded inserts on the two centers, but the structure of the camera wouldn’t allow for that, so I settled for two tie down points. Working this project in with the other projects that are ongoing in the shop, I only had time to do the basic machining so far. I didn’t want the lightening pockets to show when the baseplates are installed, so they will be machined on the side of the baseplate that sits against the camera body. I laid out the necessary tool paths and hope to have time to complete his work in the next couple of days.