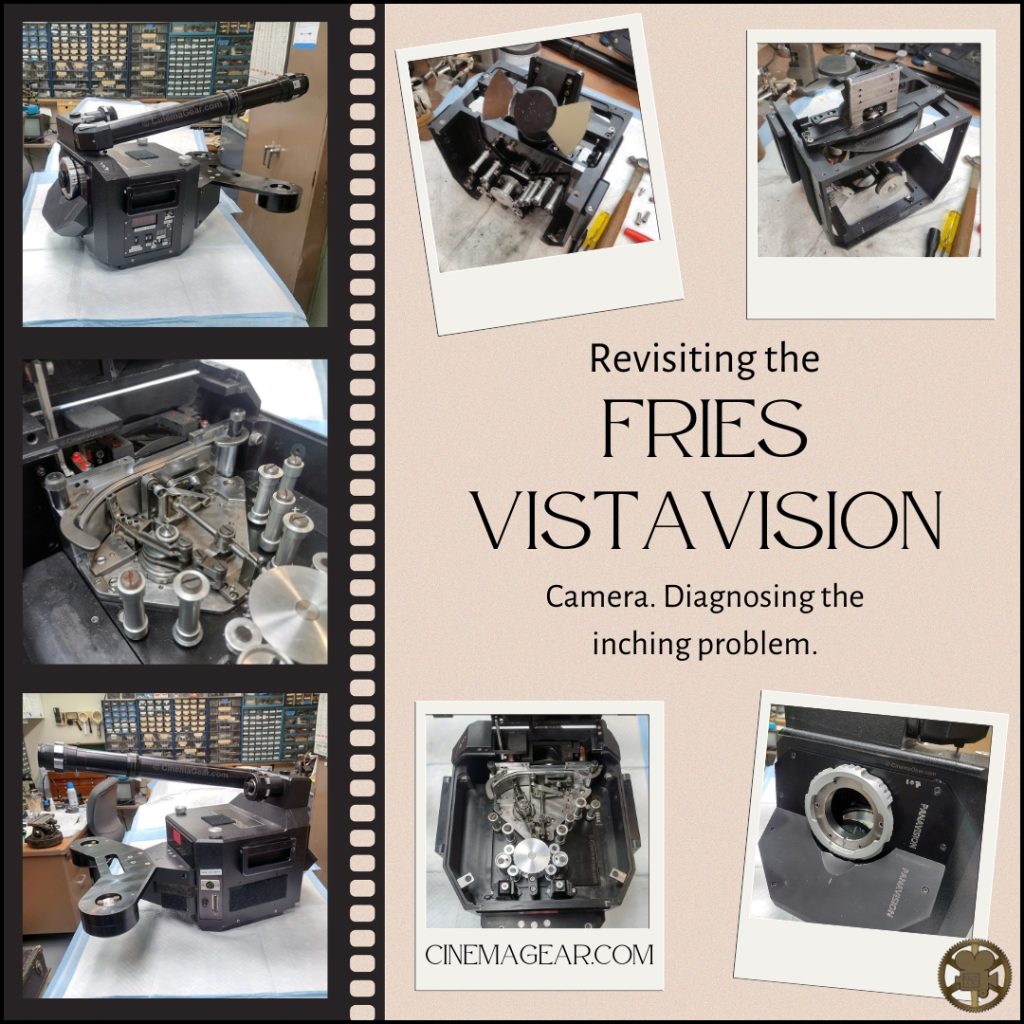

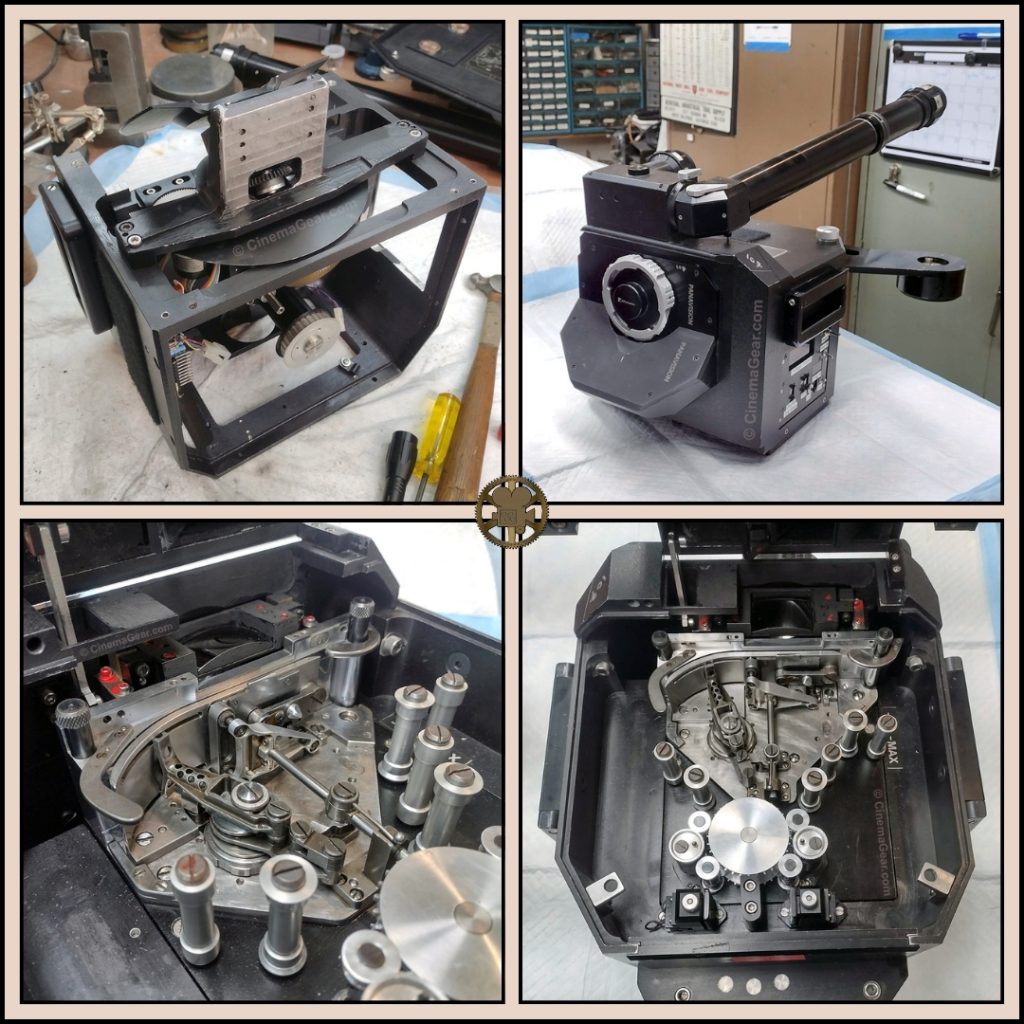

I know I said it was going to be a couple of weeks before I reported back on the problem with this Fries VistaVision camera, and at the time, it seemed it was going to take a lot more detective work. It turns out that the problems were simpler than I feared. The first problem turned out to be a combination of dirt and wear and tear. The focal plane shutter and the mirrored shutter are part of one assembly that has a set of angled gears that drive the mirrored shutter from the focal plane shutter’s driveshaft. It appears that over time, the screws that hold this shutter assembly to the main body of the camera had become ever so slightly loosened, causing one of the tight spots that could be felt when inching the camera. Additionally, it appears that it had been quite a long time since the camera was last cleaned and lubricated, so there was quite a bit of dirt and debris mixed into the grease on the gears. That accentuated this tight spot when inching. Tightening the screws and cleaning and re-lubricating the angled gears in the shutter drive assembly resolved two of the problems.

The third problem was between the movement, the flywheel, and the bearing assembly that operates the pull-down claw. There are a couple of precision ground spacers that keep all these components spaced correctly for smooth operation. At some point in the past, one of these spacers was left out, probably during servicing. With a couple of quick measurements with a height gauge and figuring out what the spacing should be, I was able to replace the missing spacer. This resolved the last of the tight spots I felt when inching the camera. Fresh grease and oil on everything, a quick check of the timing, and now the camera seems to be working correctly. It is currently off to Arnold Peterson so he can go through all of the electronics and make sure that is all working properly. Next stop, out on production! I am still out of town at my daughter’s law school graduation, so that is all for now.