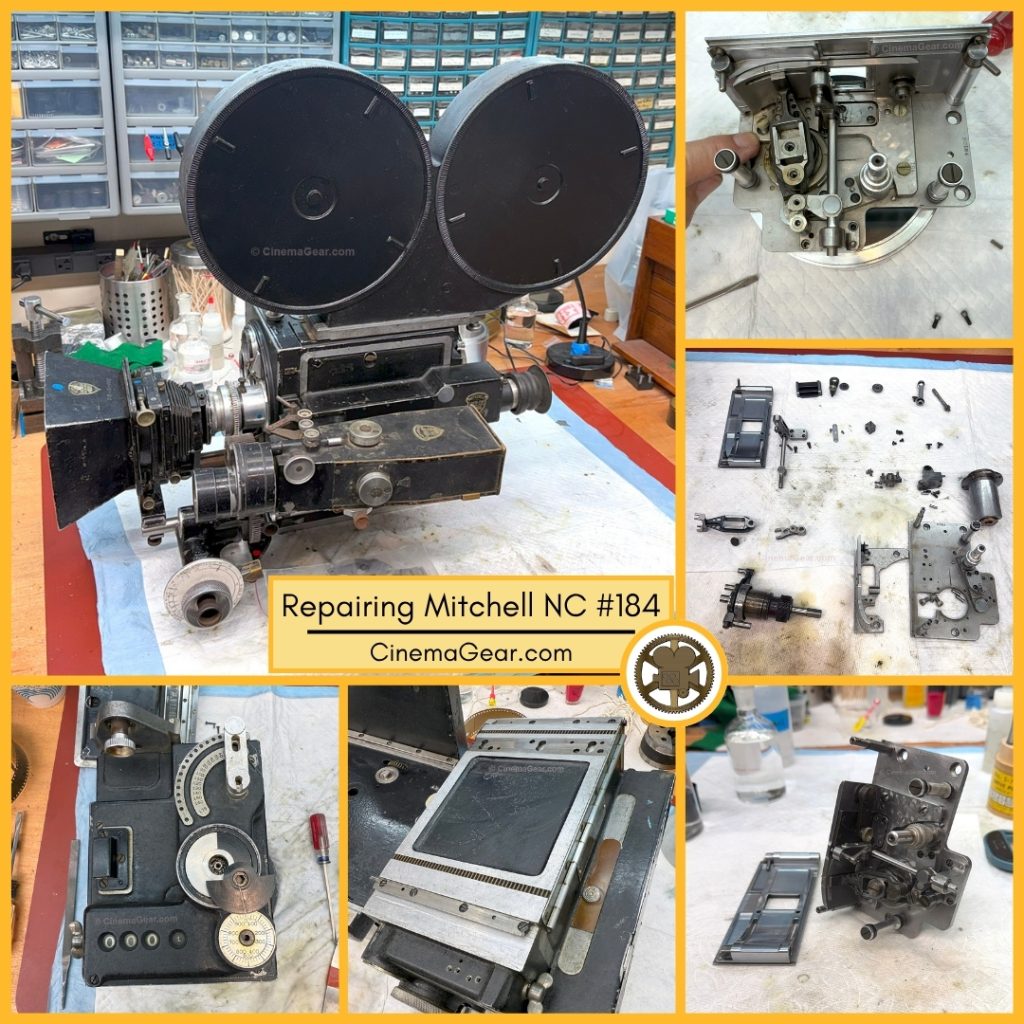

Recently I shared this amazing Mitchell NC camera with the most unusual follow focus system I have seen in a long time. The camera came here with the idea that I would find it a new home. To begin assessing its condition, I tried to turn the camera over by hand. This was not possible because everything was frozen.

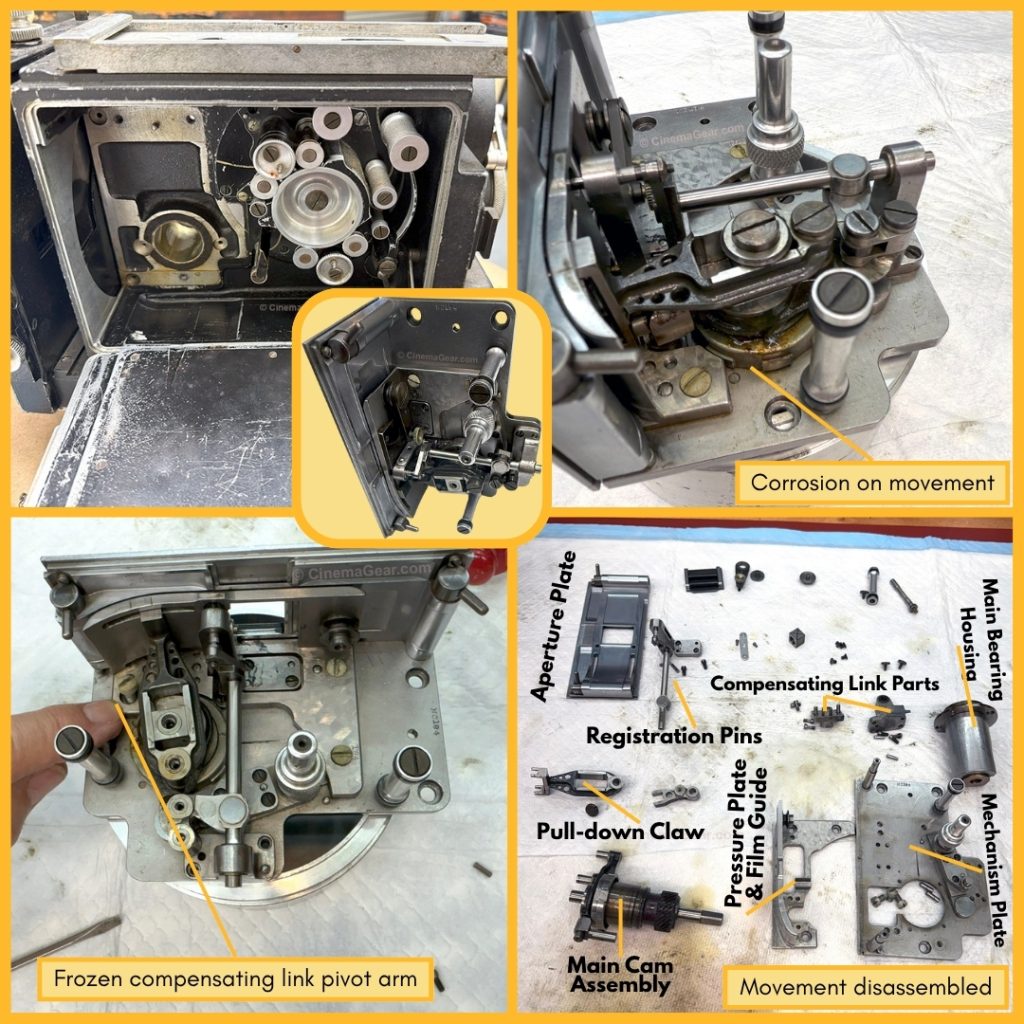

Sometime in this camera’s history, Zerk fittings had been installed in the lubrication ports for the shutter shaft, so I suspected that the grease in there had solidified, and that’s why everything was frozen. I pulled the movement from the camera, hoping it would be easy to service, but to my horror, it was locked up as well. Mitchell NC cameras are fitted with Mitchell compensating link movements, which can’t be disassembled unless the pull-down claw and registration pin assemblies are in the loading position so the aperture plate can be removed.

Because the movement was so frozen, I could not remove the aperture plate, which meant I was unable to disassemble the movement in the usual way. After much consideration and tinkering, I decided I could remove the compensating link pivot arm assembly. This would then let me move the registration pins and pull-down claws as far away from the aperture plate as possible so the aperture plate could be removed. With the aperture plate removed, the dowel pins and screws that hold the pressure/backing plate assembly in place were removed and that assembly slid forward and off the movement. Finally, I could proceed with the mostly normal disassembly for the rest of the movement parts.

The major damage was in the compensating link pivot arm assembly. With this highly irregular method of removing the compensating link pivot arm assembly from the movement complete, I soaked it in penetrating oil, applied heat a few times until I could get the pivot arm free from its bearings, and assessed the damage. These 5 parts are hand fitted and lapped at the factory for absolute precision movement of the pull-down claw and registration pin assemblies. I found that rust had settled into where the parts fit together, seizing them together and causing some pitting. Hats off to my dear friend Peter Anderson, he and I have been trying to convince our colleagues that regular maintenance is an absolute must for machines like this in order to preserve them. I stoned and lapped the damaged parts to where they would fit together reasonably well and operate smoothly, and finally reassembled the movement.

Then I took the shutter shaft and dissolve assemblies out of the camera, cleaned out all the petrified grease, re-lubricated and reassembled the shutter mechanism, reinstalled the movement, and timed the camera. Lastly, the dovetails on the L-base were not set correctly, so that was adjusted so the camera would rackover smoothly. With this labor of love completed, we now had a working Mitchell NC camera. And I am delighted that it has already found a loving new home with a dedicated collector.