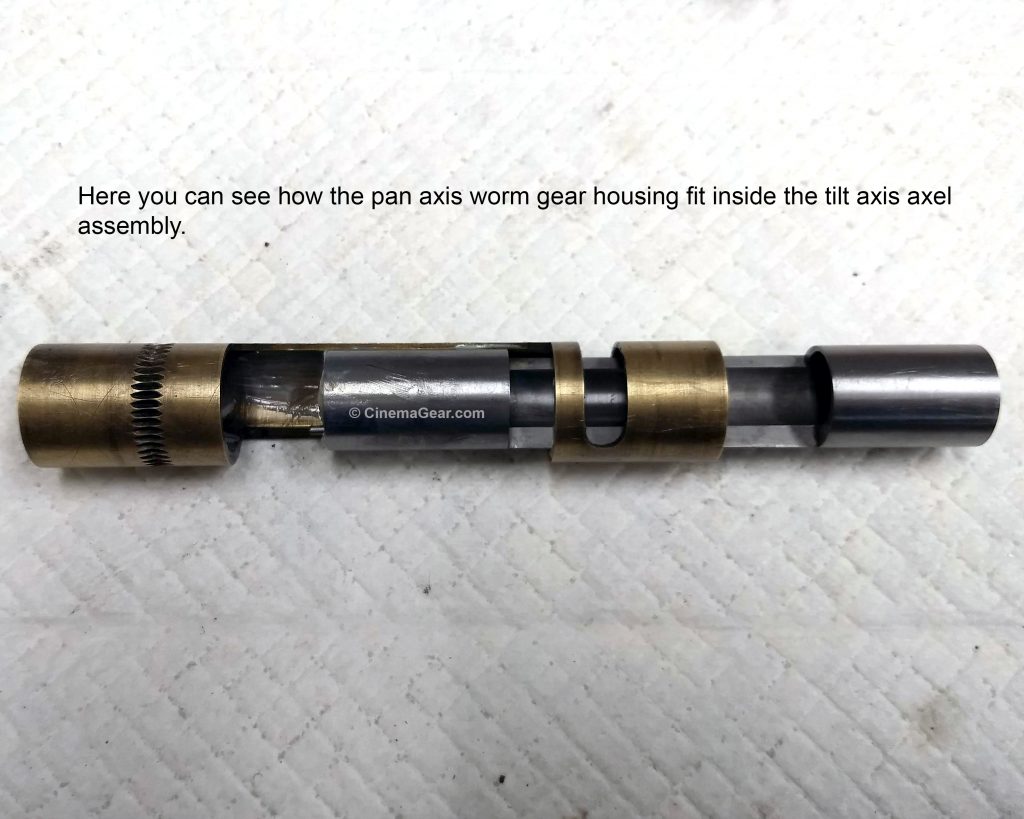

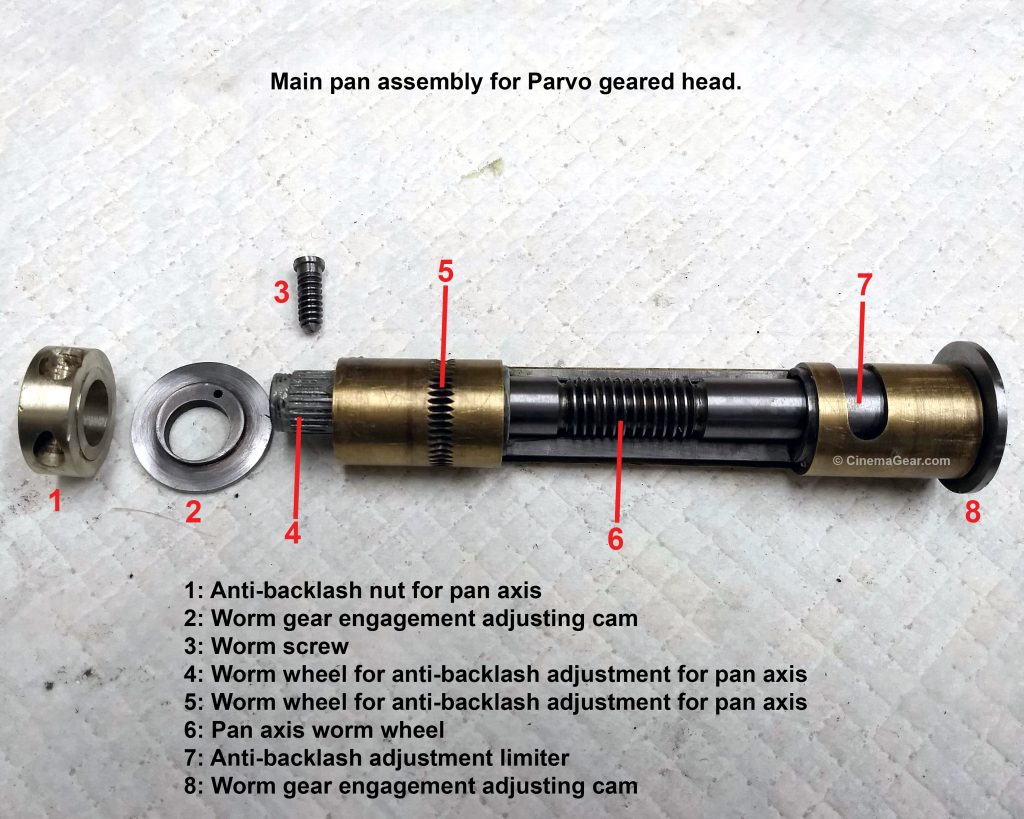

During the disassembly, de-greasing, and reassembly of the Parvo pan tilt head, I was fascinated by the unique anti-backlash adjustment features of the pan and tilt axes. This geared head only tilts down from the horizontal position, an interesting limitation. The hinge point for tilt and the worm gear that operates pan live in the same housing, making for a very compact unit. Most interesting is how the designers solved the endplay backlash, as well as the engagement of the worm gears in the pan drive assembly. The ingenious solution was to use a jam nut that is operated by a worm screw to take out endplay, and a set of end-cap cams that are also adjusted by a worm screw to adjust the engagement between the worm gear and worm wheel that run the pan.

Take a look at parts 1, 3, and 4 in photo 3. Part 1 is the jam nut, part 3 is a worm screw, and part 4 is one of two worm wheels. When assembled, the jam nut threads on the end of the pan drive shaft and the worm screw engages with the threads machined in the main drive shaft to adjust endplay and remove as much backlash as possible. Parts 2 and 8 are off-set cams that fit like hubs in the brass tilt axel. Another worm screw engages in part 5 to rotate the whole housing, which brings the worm gear and worm wheel for the pan axis closer together or further apart for proper engagement.